Preparation method of walnut meat and glutinous rice nutrition vinegar powder

A technology of walnut meal powder and walnut meal, which is applied in the field of preparation of nutritional vinegar powder, walnut meal glutinous rice nutritional vinegar powder, can solve the problems of not easy to carry and store, complex production process, inconvenient use, etc., and achieve convenient transportation and easy storage , Ease of use and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

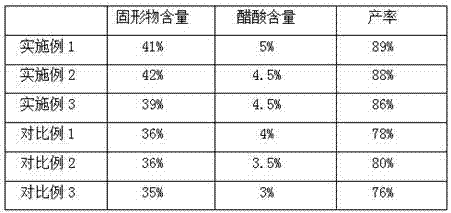

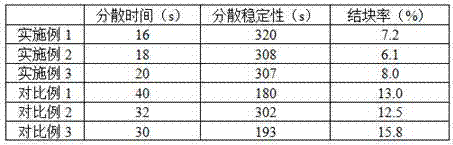

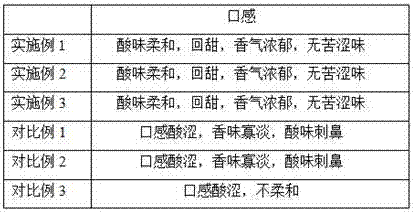

Examples

Embodiment 1

[0033] (1) Blast-dry the cold-pressed walnut meal at a temperature of 40°C until the moisture content is 5%;

[0034] (2) Coarsely crush the dried jujube granules at a temperature of -4°C, and then dry them at a temperature of 40°C until the jujube granules have a moisture content of 5%;

[0035] (3) Grind the dry walnut meal powder and glutinous rice in step (1) at room temperature to a particle size of 500 mesh for later use; use a low-temperature vibrating mill to pulverize the coarse jujube particles in step (2) at a temperature below zero At 10°C, pulverize jujube superfine powder with a particle size of 200 mesh; freeze the raisins thoroughly at minus -18°C, and then crush them at minus 15°C to 500 mesh to obtain fine raisin powder for later use;

[0036] (4) According to the number of parts by weight, take 40 parts of walnut meal powder, 30 parts of red date superfine powder, 10 parts of raisin fine powder and 25 parts of glutinous rice flour, add 60% water and heat at ...

Embodiment 2

[0043] (1) Dry the cold-pressed walnut pulp at a temperature of 40°C to a moisture content of 5%.

[0044] (2) Coarsely crush the dried jujube granules at a temperature of -4°C, and then dry them at a temperature of 40°C until the jujube granules have a moisture content of 5%;

[0045] (3) Grind the dry walnut meal powder and glutinous rice in step (1) at room temperature to a particle size of 500 mesh for later use; use a low-temperature vibrating mill to pulverize the coarse jujube particles in step (2) at a temperature below zero At 10°C, pulverize jujube superfine powder with a particle size of 200 mesh; freeze the raisins thoroughly at minus -18°C, and then crush them at minus 15°C to 500 mesh to obtain fine raisin powder for later use;

[0046] (4) According to the number of parts by weight, take 30 parts of walnut meal powder, 20 parts of jujube superfine powder, 15 parts of raisin fine powder and 40 parts of glutinous rice flour, add 60% water and heat at 95 ° C for 30 m...

Embodiment 3

[0053] (1) Dry the cold-pressed walnut pulp at a temperature of 40°C to a moisture content of 5%.

[0054] (2) Coarsely crush the dried jujube granules at a temperature of -4°C, and then dry them at a temperature of 40°C until the jujube granules have a moisture content of 5%;

[0055] (3) Grind the dry walnut meal powder and glutinous rice in step (1) at room temperature to a particle size of 350 mesh for later use; use a low-temperature vibrating mill to pulverize the coarse jujube particles in step (2) at a temperature below zero At 10°C, pulverize the jujube superfine powder with a particle size of 350 mesh; freeze the raisins thoroughly at minus -18°C, and then crush them at minus 8°C to 300 mesh to obtain raisin fine powder, which is set aside;

[0056] (4) According to the number of parts by weight, take 35 parts of walnut meal powder, 25 parts of red date superfine powder, 12 parts of raisin fine powder and 30 parts of glutinous rice flour, add 50% water and heat at 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com