Haze-removal and carbon-reduction micro-algae cultivation system for flue gas and flue gas treatment method

A haze-reducing carbon-reducing microalgae and culture system technology, applied in the field of flue gas treatment equipment using microalgae, can solve problems such as aggravation of haze and greenhouse effect, flue gas pollution environment, and environmental changes of algae open-air cultivation, so as to avoid Haze and greenhouse effect, improving breeding efficiency, reducing haze and greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

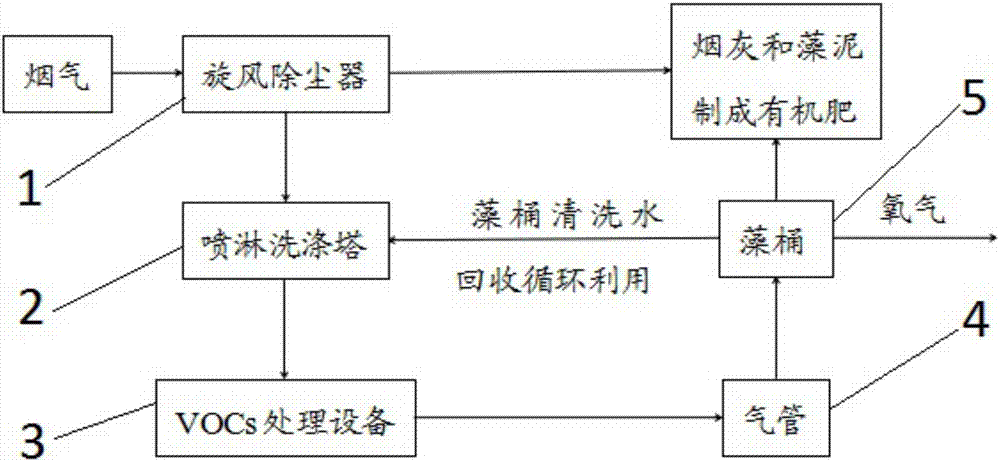

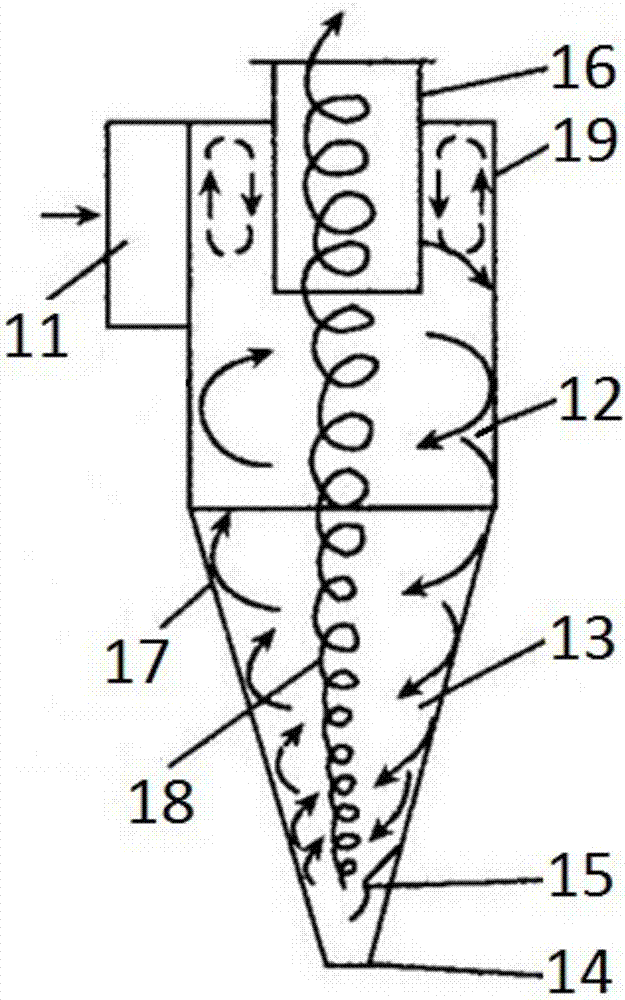

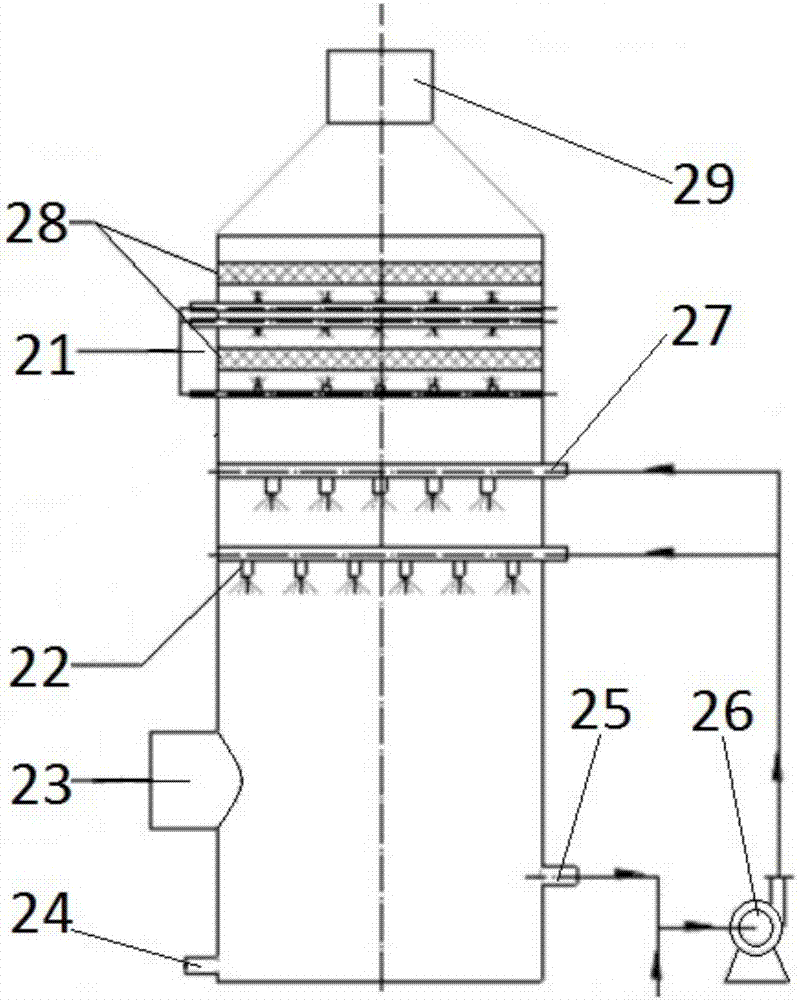

[0030] figure 1 Schematically shows the flow chart of the microalgae cultivation system for gas removal, haze reduction and carbon reduction according to the present invention. As shown in the figure, the flue gas haze removal and carbon reduction microalgae cultivation system includes sequentially connected cyclone dust collectors, spray scrubbers, VOCs treatment equipment, air pipes and algae barrels and other components. The industrial flue gas discharged from the chimney of the factory passes through the cyclone dust collector, spray scrubber and VOCs treatment equipment in sequence to remove various dust, smoke and acid gas and other pollutants, and the remaining CO2 gas is input into the algae tank through the trachea In it, it is used to supply microalgae to carry out photosynthesis, produce and output fresh oxygen. In addition, the soot in the cyclo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com