Chlorine dioxide gas-phase oxidation desulfurization and denitrification integrated device and process thereof

A chlorine dioxide, oxidative desulfurization technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of oxidation speed and oxidation efficiency, increase the consumption of CLO oxidant, etc., to achieve simple implementation, convenient operation, equipment, etc. The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

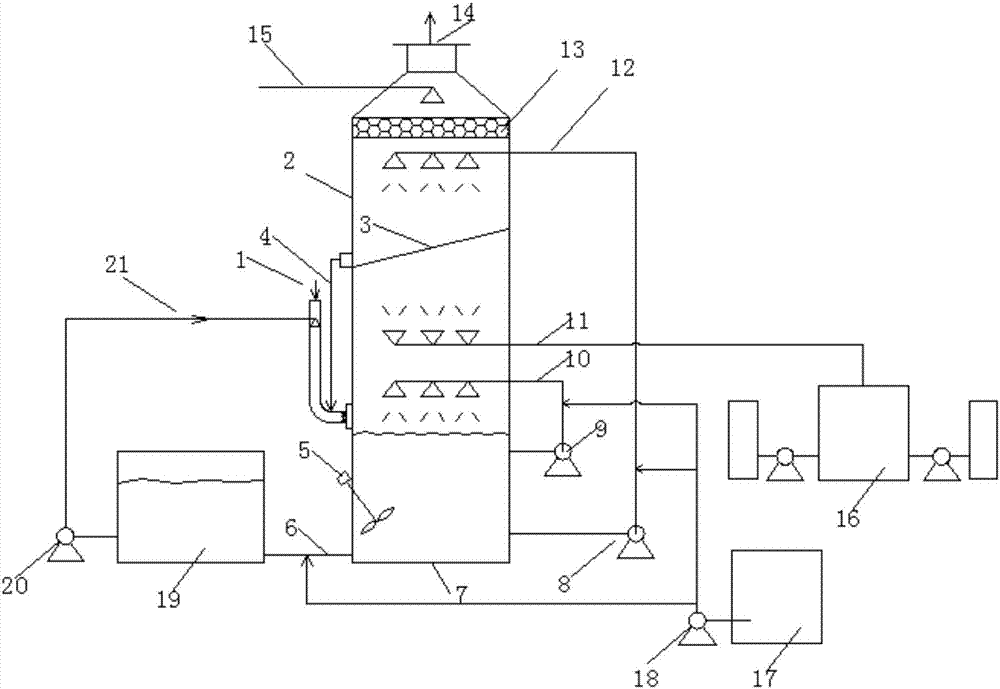

[0015] Such as figure 1 , the chlorine dioxide gas-phase oxidative desulfurization and denitrification integrated device of the present invention, its main body is an oxidation absorption tower 2, and the main body includes a two-stage tower body, and a liquid material pool 7 is arranged at the bottom of the tower body, which is located in the liquid material pool The side wall of the tower body above 7 is provided with a flue gas inlet 1; a desulfurization spray pipe 10 is arranged above the flue gas inlet 1, and a chlorine dioxide gasification spray pipe 11 is arranged above the desulfurization spray pipe 10; Above the pipe 11, there is a partition 3 that divides the inner cavity of the tower into upper and lower parts. The lower part is the desulfurization and NO gas phase oxidation tower section, and the upper part is the denitrification tower section; above the partition 3, there is a denitrification spray pipe 12. The partition 3 is set at an inclined angle, and the deni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com