Ship and naval vessel wall surface wall-climbing cleaning robot

A technology for cleaning robots and cleaning mechanisms, which is applied to grinding frames, grinding machine parts, grinding machines, etc. It can solve the problems of lack of self-adaptive structural design, inability to adapt to large curvature hull surfaces, and unreliable adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

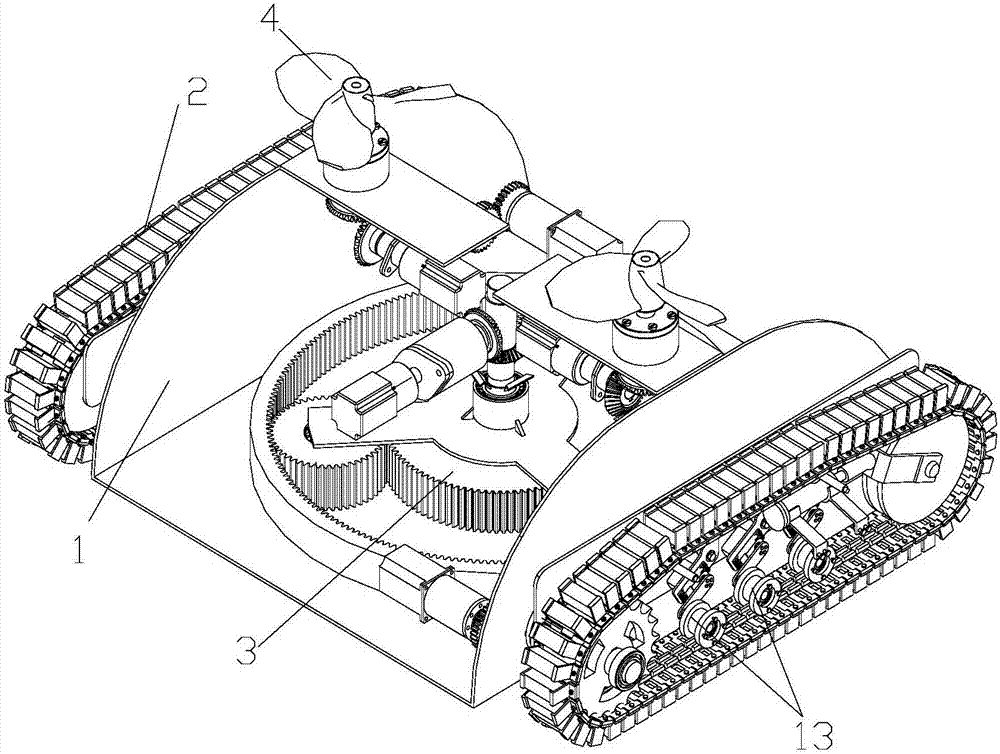

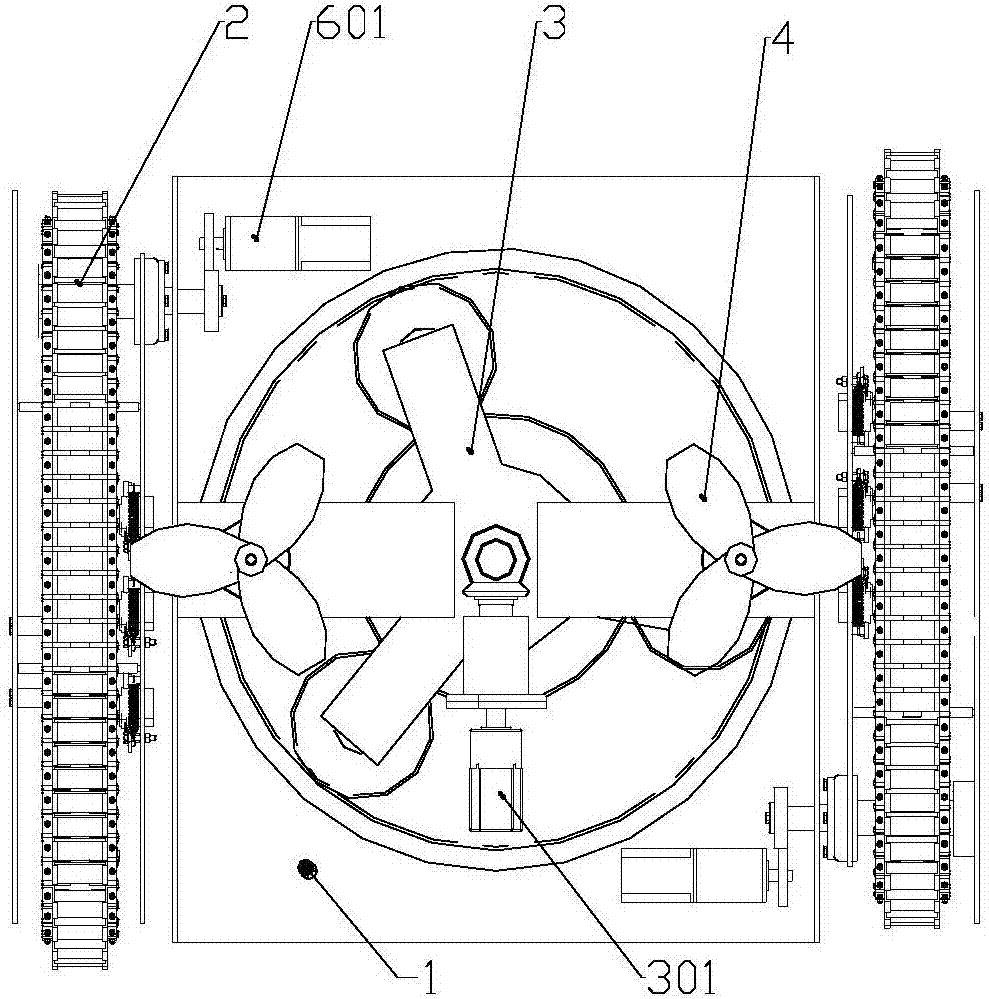

[0031] Such as Figure 1-Figure 2 A wall-climbing cleaning robot for ships and warships shown includes a vehicle frame 1 on which a walking adaptive mechanism 2 , a cleaning mechanism 3 and a thrust adsorption mechanism 4 are installed.

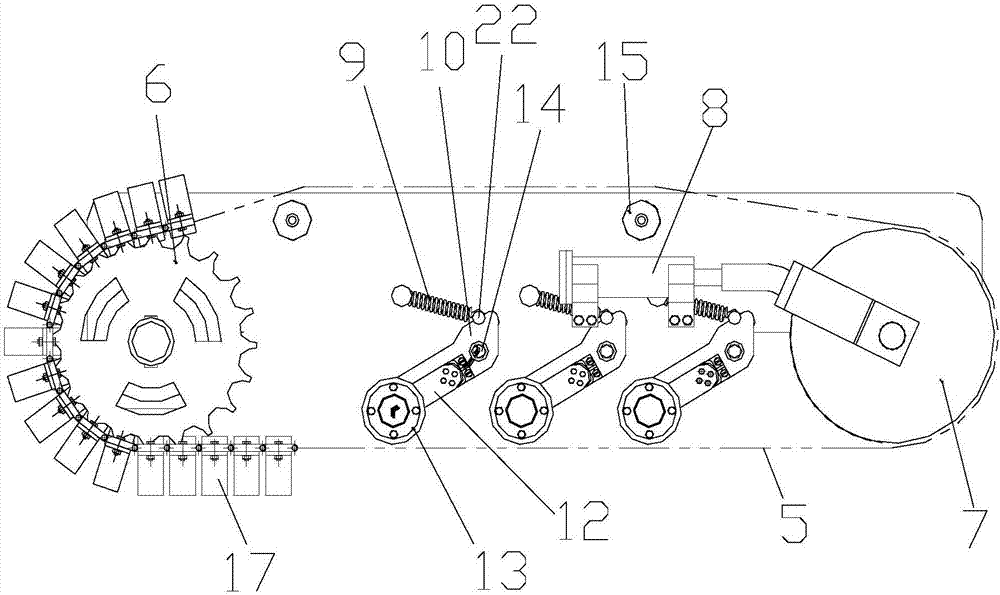

[0032] Such as image 3 with Figure 4 As shown, the walking adaptive mechanism 2 includes a crawler belt 5, and the crawler belt 5 is set on the driving wheel 6 and the tensioning wheel 7; the tensioning wheel 7 is connected with a telescopic adjustment mechanism 8, and the telescopic adjustment mechanism 8 is a hydraulic cylinder or other telescopic device. Such as cylinders, etc. An adaptive mechanism is installed between the driving wheel 6 and the tensioning wheel 7; the adaptive mechanism includes a spring 9, one end of the spring 9 is connected to the vehicle frame 1, and the other end is connected to the upper support plate 10, and the support plate 10 is connected to the vehicle frame 1 shaft through the rotating shaft 14. Connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com