Microcapsule water permeable brick and preparation method thereof

A technology of microcapsules and permeable bricks, which is applied in the field of permeable bricks for municipal construction, which can solve the problems of uneven voids, sticky stagnation, and easy agglomeration of the mixture, and achieve optimized pore distribution, improved water permeability, and good response environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

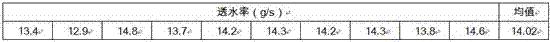

Embodiment 1

[0027] A microcapsule permeable brick and a preparation method thereof, comprising: a film-coated aggregate, a bonding substance, a curing agent and a solvent.

[0028] The film-coated aggregate uses natural quartz sand with a particle size of 0.1-0.3 mm, the film-covered resin uses bisphenol A epoxy resin E12 (softening point is 85-95 °C, average molecular weight is 1400), and the solvent uses hexane ( The boiling point is 68.7°C).

[0029] a. Heat the natural quartz sand with a particle size of 0.1-0.3mm to 150°C, put the hot sand and resin into the sand mixer for coating for 1min according to the mass ratio, mix evenly and add the hardener urotropine aqueous solution, When the sand temperature drops, add additive calcium stearate and mix evenly, and the molding sand is unloaded from the sand mixer, further crushed and cooled, and then sieved;

[0030] B, select modified epoxy curing agent T-31, adopt interfacial polymerization method, 100 parts of curing agent correspond t...

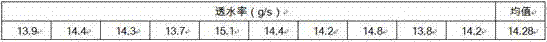

Embodiment 2

[0039] A microcapsule permeable brick and a preparation method thereof, comprising: a film-coated aggregate, a bonding substance, a curing agent and a solvent.

[0040] The coated aggregate uses natural quartz sand with a particle size of 0.1-0.3 mm, the coated resin uses bisphenol A epoxy resin E12 (softening point is 85-95 °C, average molecular weight is 1400), and the solvent uses trifluoro Acetic acid (boiling point 71.1°C)

[0041] a. Heat the natural quartz sand with a particle size of 0.1-0.3mm to 150°C, put the hot sand and resin into the sand mixer for coating for 1min according to the mass ratio, mix evenly and add the hardener urotropine aqueous solution, When the sand temperature drops, add additive calcium stearate and mix evenly, and the molding sand is unloaded from the sand mixer, further crushed and cooled, and then sieved;

[0042] B, select modified epoxy curing agent T-31, adopt interfacial polymerization method, 100 parts of curing agent correspond to 3 p...

Embodiment 3

[0051] A microcapsule permeable brick and a preparation method thereof, comprising: a film-coated aggregate, a bonding substance, a curing agent and a solvent.

[0052] The film-coated aggregate uses natural quartz sand with a particle size of 0.1-0.3 mm, the film-covered resin uses bisphenol A epoxy resin E12 (softening point is 85-95 °C, average molecular weight is 1400), and the solvent uses hexane ( The boiling point is 68.7°C)

[0053] a. Heat the natural quartz sand with a particle size of 0.1-0.3mm to 150°C, put the hot sand and resin into the sand mixer for coating for 1min according to the mass ratio, mix evenly and add the hardener urotropine aqueous solution, When the sand temperature drops, add additive calcium stearate and mix evenly, and the molding sand is unloaded from the sand mixer, further crushed and cooled, and then sieved;

[0054] b, select modified epoxy curing agent H-113, adopt interfacial polymerization method, 100 parts of curing agent correspond t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap