A method for fabricating durable micro-nano structures on curved glass

A technology of curved glass and micro-nano structure, which is applied in the direction of photolithography, nanotechnology, optomechanical equipment, etc. on the patterned surface to achieve high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

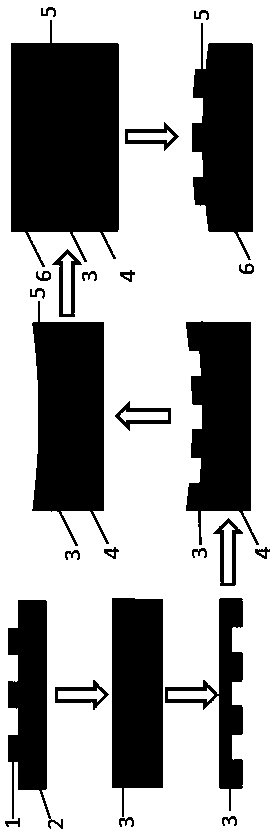

[0024] Specific implementation methods: such as figure 1 As shown, a method for preparing durable micro-nano structures on curved glass is completed by the following steps:

[0025] S1: Synthesis of a new photosensitive sol-gel hybrid glass material, the synthesis steps are as follows:

[0026] S11: Mix 3-(trimethoxysilyl)propylmethacrylate (3-trimethoxysilyl propylmethacrylate) with isopropanol and water in a molar ratio of 0.04:0.048:0.053, and hydrolyze it to form a first solution;

[0027] S12: making metal organic tetraisopropoxytitanium and acetylacetone in a nitrogen environment at a molar ratio of 1:4 to prepare a second solution;

[0028] S13: After standing still for 30 minutes, mix the prepared two solutions according to a specific ratio, and prepare sol-gel mixed glass materials with different refractive indices by adjusting the proportion of the second solution in the mixed solution. 1.46-2.95, making it the same as the refractive index of the curved glass used;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com