Underground water nitrate removal method and denitrification reactor

A groundwater and nitrate technology, applied in the direction of contaminated groundwater/leachate treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of excessive pollutants and achieve the effect of improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a method for removing groundwater nitrates, comprising the following steps:

[0044] In the first step, anode electrolysis produces oxygen and CO 2 , anodic heterotrophic aerobic denitrifying bacteria preliminarily reduced nitrate in groundwater in the anode area;

[0045] In the second step, cathode electrolysis produces hydrogen, and hydrogen autotrophic denitrifying bacteria further reduce the groundwater obtained in the first step in the cathode area.

[0046] The nitrate removal rate of the groundwater entering the cathode reaction zone is over 82%.

Embodiment 2

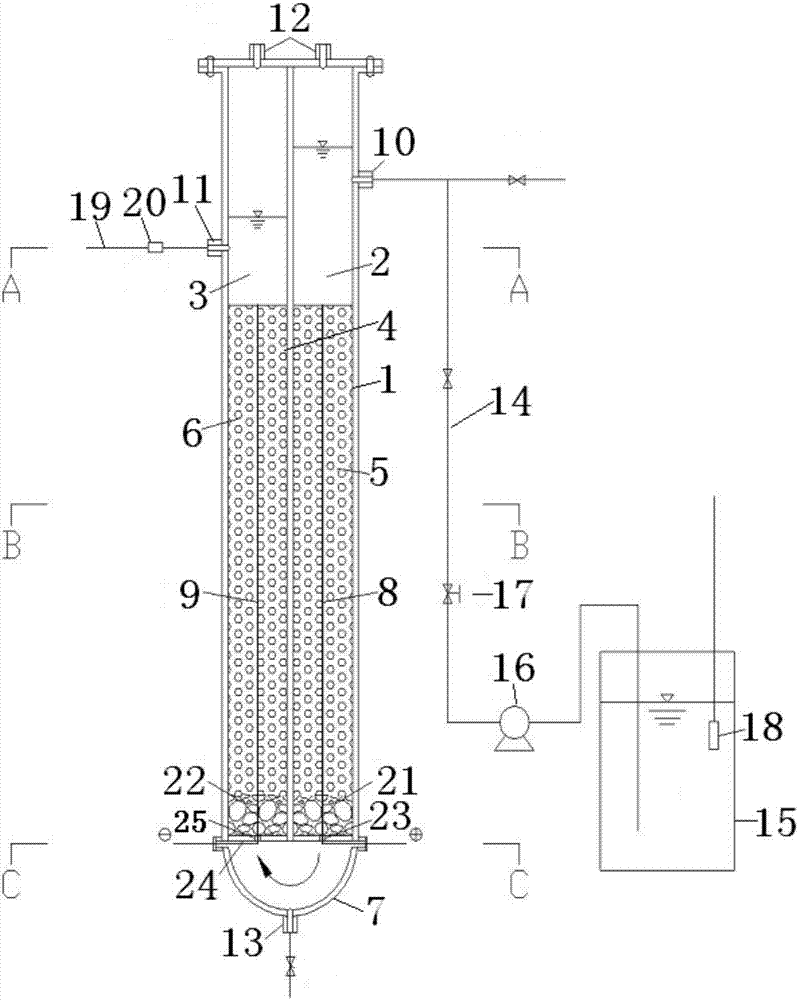

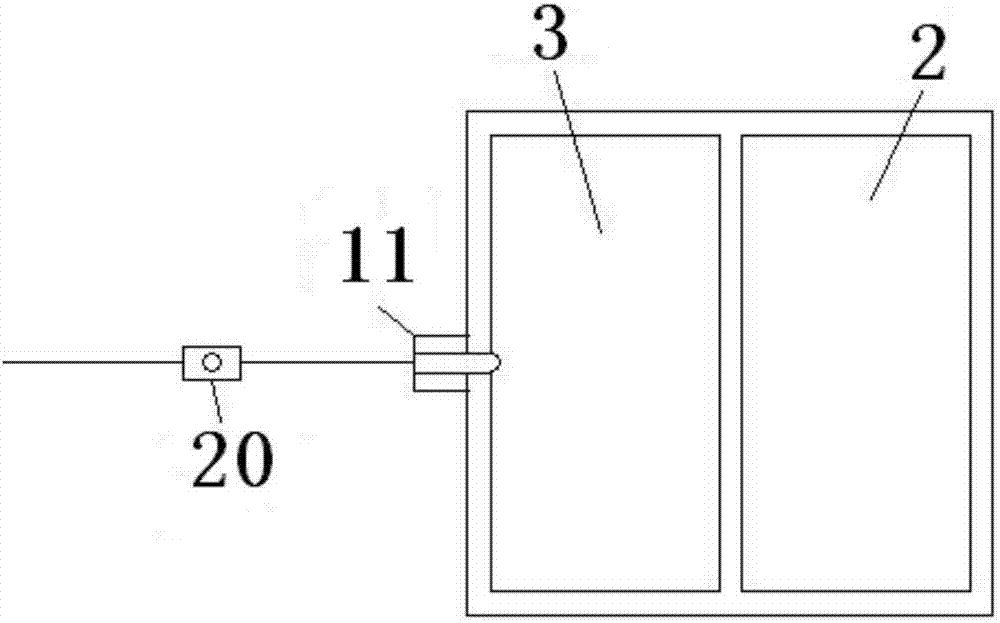

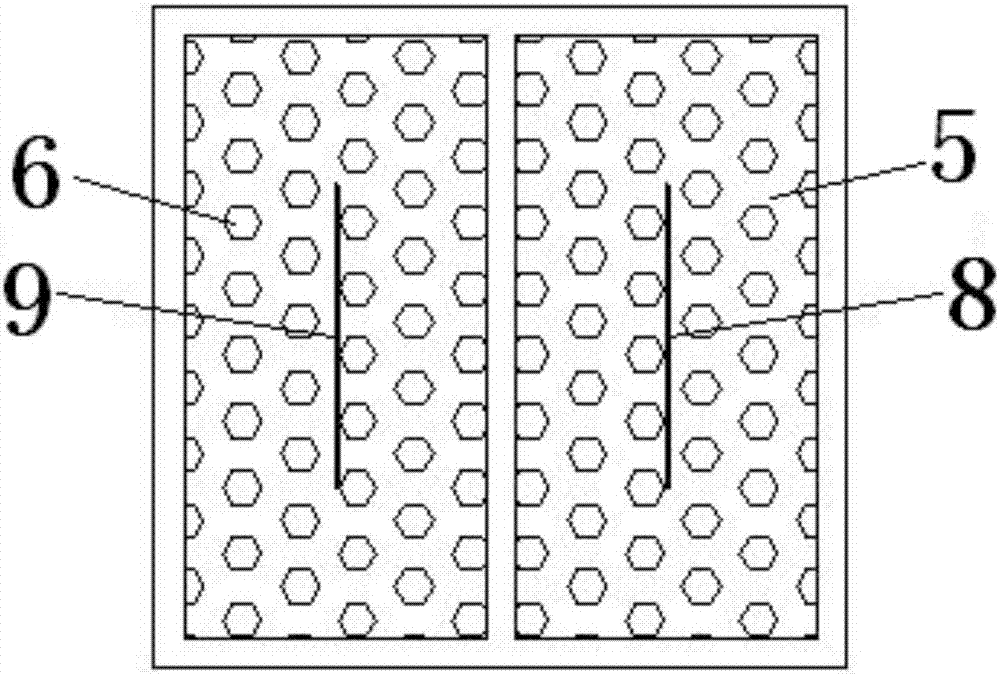

[0048] This embodiment provides a denitrification reactor, such as Figure 1-4 As shown, a housing 1 comprising a lower opening, the housing 1 is vertically provided with an anode reaction zone 2 and a cathode reaction zone 3, and the anode reaction zone 2 and the cathode reaction zone 3 are separated by a separator 4; the anode reaction zone 2 The anode filler 5 and the cathode filler 6 are respectively included in the cathode reaction zone 3, and the anode filler 5 and the cathode filler 6 are respectively attached with heterotrophic aerobic denitrifying bacteria and hydrogen autotrophic denitrifying bacteria, and the lower part of the housing 1 is connected with a semi-cylindrical Bottom cover7. The groundwater first enters the anode reaction zone 2, and the heterotrophic aerobic denitrifying bacteria use the oxygen produced by the anode electrolysis as the oxygen source to initially reduce the nitrate in the groundwater, and the reduced groundwater enters the cathode react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com