Preparation method of di-N-octyltin oxide

A technology of dioctyltin oxide and dioctyltin dichloride, which is applied in the field of preparation of dioctyltin oxide, can solve the problems of many steps, high toxicity of organotin chloride, and high additional cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

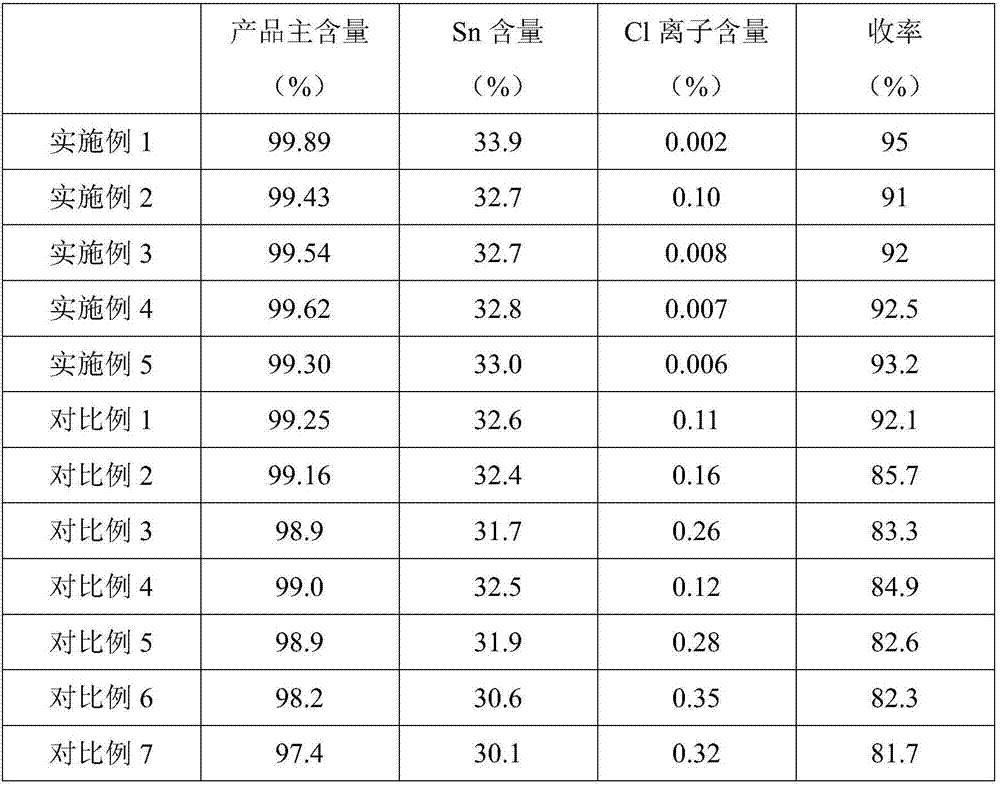

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of dioctyltin oxide, comprises the following steps:

[0029] (1) Add tetraoctyltin chloride, activated clay, modified diatomite in the reactor, feed nitrogen, after stirring evenly, slowly add tin tetrachloride dropwise, after the dropwise addition, stir for 30min, heat up to 160-190°C, heat preservation reaction for 4-8h, filter to obtain dioctyltin dichloride;

[0030] (2) Add isopropanol and surfactant to step (1), slowly add sodium hydroxide solution dropwise, after the dropwise addition, heat up to 75-80°C, keep the temperature for 4-6h, cool down to room temperature, filter, To obtain the crude dioctyltin oxide, wash the crude dioctyltin oxide with water until it becomes neutral, and dry it under reduced pressure at 80°C for 12 hours to obtain dioctyltin oxide;

[0031] Wherein, the modified diatomite is dodecylamine polyoxyethylene ether modified diatomite; the surfactant is chitosan modified imidazoline amphot...

Embodiment 1

[0069] The preparation method of described dioctyltin oxide comprises the following steps:

[0070] (1) Add tetraoctyltin chloride, activated clay, modified diatomite in the reactor, feed nitrogen, after stirring evenly, slowly add tin tetrachloride dropwise, after the dropwise addition, stir for 30min, heat up to 180°C, keep warm for 6 hours, filter to obtain dioctyltin dichloride;

[0071] (2) Add isopropanol and surfactant to step (1), and slowly add sodium hydroxide solution dropwise. After the dropwise addition, heat up to 80°C, keep the temperature for 5 hours, cool down to room temperature, and filter to obtain dioctyl For crude tin oxide, wash the crude dioctyltin oxide with water until neutral, and dry under reduced pressure at 80°C for 12 hours to obtain dioctyltin oxide;

[0072] Wherein, the weight ratio of tetraoctyltin chloride to the activated clay and the modified diatomite in the step (1) is 1:0.09:0.13; the tetraoctyltin chloride in the step (1) The mol rat...

Embodiment 2

[0084] The preparation method of described dioctyltin oxide comprises the following steps:

[0085] (1) Add tetraoctyltin chloride, activated clay, modified diatomite in the reactor, feed nitrogen, after stirring evenly, slowly add tin tetrachloride dropwise, after the dropwise addition, stir for 30min, heat up to 180°C, keep warm for 6 hours, filter to obtain dioctyltin dichloride;

[0086] (2) Add isopropanol and surfactant to step (1), and slowly add sodium hydroxide solution dropwise. After the dropwise addition, heat up to 80°C, keep the temperature for 5 hours, cool down to room temperature, and filter to obtain dioctyl For crude tin oxide, wash the crude dioctyltin oxide with water until neutral, and dry under reduced pressure at 80°C for 12 hours to obtain dioctyltin oxide;

[0087] Wherein, the weight ratio of tetraoctyltin chloride to the activated clay and the modified diatomite in the step (1) is 1:0.05:0.2; the tetraoctyltin chloride in the step (1) The mol rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com