Strain for directly producing butanol by utilizing xylan as sole carbon source and application of strain

A technology for producing butanol and xylan, applied in the field of microorganisms, can solve problems such as increased production cost, unfavorable industrial production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Isolation and screening of thermophilic strain Thermoanaerobacterium thermosaccharolyticum M5 using xylan as the sole carbon source:

[0029] Weigh 1 g of soil samples taken from Inner Mongolian haystacks, dilute them with physiological saline, draw 200 μL onto a plate with xylan as the sole carbon source, and culture them anaerobically at 60°C for 5 days. The grown colonies were streaked and purified for 5 generations to screen out the strains that can directly utilize xylan and are thermophilic.

[0030] The medium formula of above-mentioned flat plate is NaCl 1g / L, K2 HPO 4 0.75g / L, KH 2 PO 4 0.75g / L, yeast powder 3g / L, CaCl 2 ·2H 2 O 0.015g / L, FeCl 2 ·4H 2 O 1.5g / L, KCl 0.3g / L, adjust pH to 6.5, xylan 30g / L, add agar powder 15-20g / L to solid medium, pass nitrogen for 10-20min, sterilize at 121°C for 15min.

Embodiment 2

[0032] Identification and growth characteristics of a thermophilic strain Thermoanaerobacterium thermosaccharolyticum M5 using xylan as the sole carbon source:

[0033] Identification of M5:

[0034] 16S rDNA identification of DL-10: The 16S rDNA of strain M5 was amplified using primers 27F: 5'-AGAGTTTGATCCTGGCTCAG-3' and 1492R: 5'-TACCTTGTTACGACTT-3', and ligated to the cloning vector pMD19T by means of T / A cloning , construct the recombinant cloning vector pMD19T-16S, transform it into the cloned host strain Escherich coli DH5α to obtain the recombinant microorganism Escherich coli DH5α (pMD19T-16S), sequence the obtained exogenous fragments of the recombinant microorganism, and compare the 16S rDNA in the NCBI database. Sequence, the strain M5 was identified to the genus Thermoanaerobacterium thermosaccharolyticum at the molecular level, and the nucleotide sequence of its 16S rDNA is shown in SEQ ID NO: 1 in the sequence listing.

[0035] M5 Growth and Metabolic Properties...

Embodiment 3

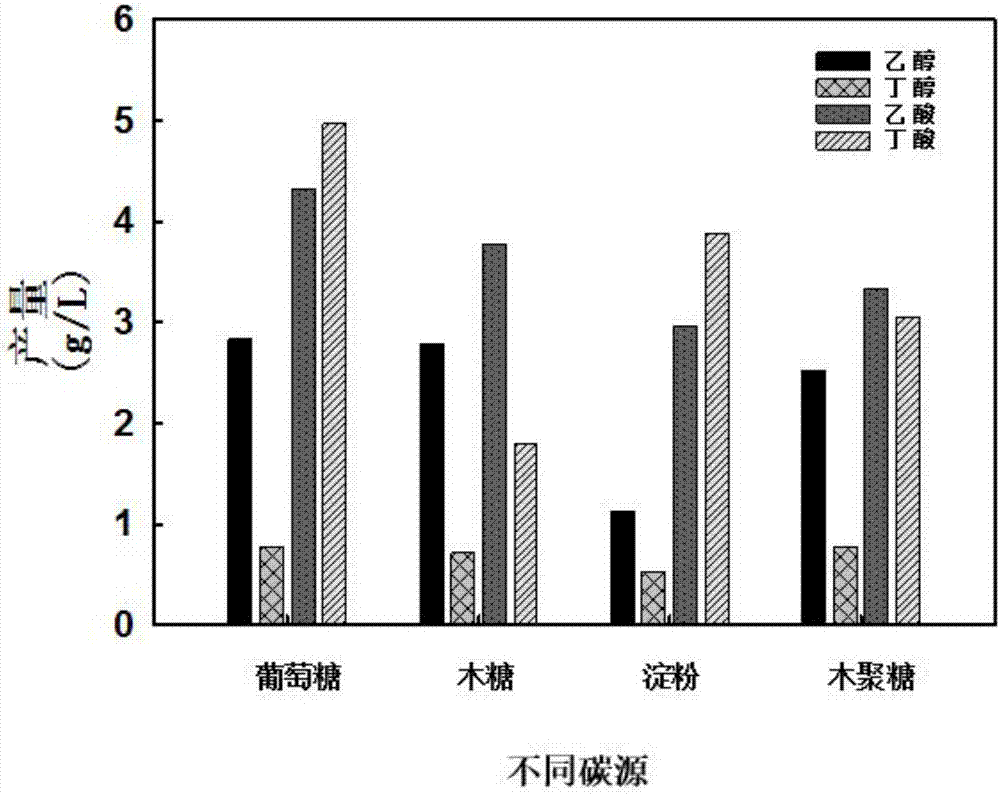

[0038] The thermophilic strain Thermoanaerobacterium thermosaccharolyticum M5 using xylan as the sole carbon source utilizes different carbon sources for growth and fermentation characteristics:

[0039] The strain Thermoanaerobacterium thermosaccharolyticum M5 can use glucose, xylose, starch, xylan and other monosaccharides or polysaccharides as carbon sources for growth ( figure 1 ). Strain Thermoanaerobacterium thermosaccharolyticum M5 Pick a single colony of strain M5 from the plate and inoculate it into 5ml fermentation medium, 60℃, 120r·min -1 Cultured for 48h, then inoculated into the fermentation medium with an inoculum volume of 5% v / v, 60°C, 120r·min -1 The culture was shaken, the pH was adjusted to 6.0-6.2 every 24h, and the concentrations of various products were measured by GC after 72h. The concentration of fermentation products after 120h fermentation was as follows: ethanol 2.52g / L, butanol 0.78g / L, acetic acid 3.34g / L, butyric acid 3.05g / L.

[0040] Above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com