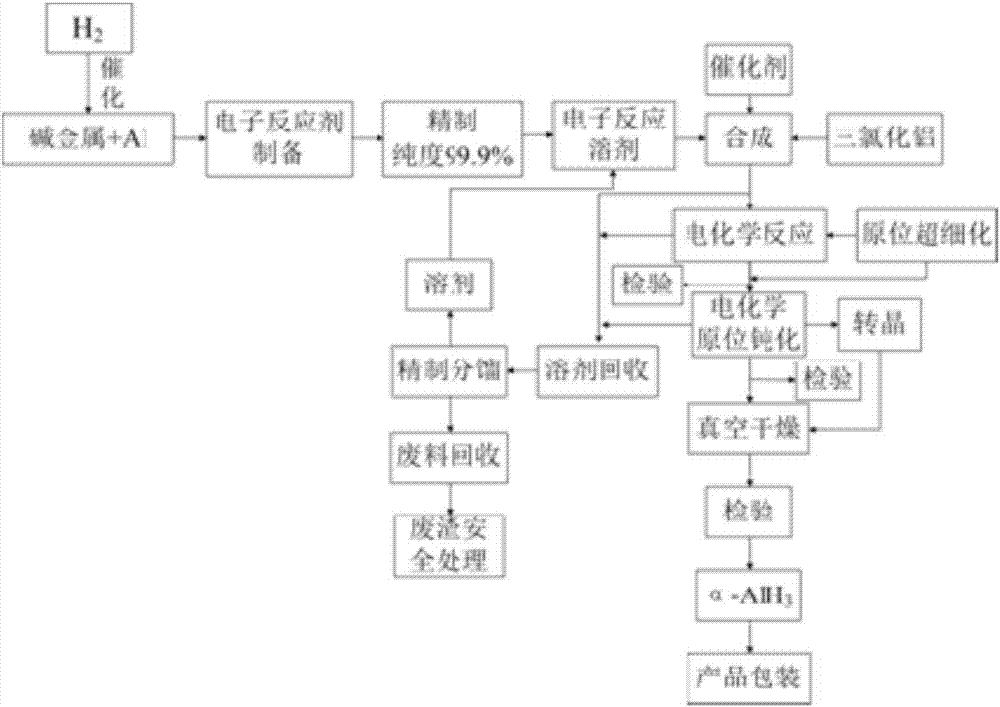

Method for preparing alpha-aluminum trihydride through electrochemical catalytic deposition

A kind of aluminum trihydride, electrochemical technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of high environmental requirements, can not meet the weapons and equipment, slow gas release, decomposition and other problems, achieve high yield and selectivity, direct reaction. The effect of low cost and low energy consumption of electrolysis reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing α-aluminum hydride by electrochemical catalytic deposition, comprising the following steps:

[0021] (1) Refining of sodium aluminum hydride: take 500g of sodium aluminum hydride, add 0.8L of refined anhydrous ether, stir, then add 2L of unrefined anhydrous ether, continue stirring for 3min, then add 1.0L of unrefined toluene, stir 5min, stand still for 8h; filter the mixed solution after standing still under reduced pressure, distill the filtrate under normal pressure at 90°C, distill off the solvent and recover it for later use, then filter the distilled product with suction and dry under vacuum conditions of 280mmHg and 40°C for 5h to obtain Refined sodium aluminum hydride.

[0022] (2) Electrochemical catalysis prepares α-aluminum trihydride: get the refining sodium aluminum hydride that step (1) obtains and dissolve in ether, carry out vacuum distillation, form electrolytic solution, the concentration of electrolytic solution is 0.05mol / L; T...

Embodiment 2

[0025] A method for preparing α-aluminum hydride by electrochemical catalytic deposition, comprising the following steps:

[0026] (1) Refining of sodium aluminum hydride: Take 1000g of sodium aluminum hydride, add 2.5L of refined anhydrous ether, stir, then add 2L of unrefined anhydrous ether, continue stirring for 3min, then add 3.0L of unrefined toluene, stir 25min, stand still for 16h; filter the mixed solution after standing still under reduced pressure, distill the filtrate under normal pressure at 140°C, distill off the solvent and recover it for later use, then filter the distilled product with suction, under the condition of vacuum degree of 495mmHg and 75°C Dry for 2h to obtain refined sodium aluminum hydride.

[0027] (2) Electrochemical catalysis prepares α-aluminum trihydride: get the refining sodium aluminum hydride that step (1) obtains and dissolve in ether, carry out vacuum distillation, form electrolytic solution, the concentration of electrolytic solution is...

Embodiment 3

[0030] A method for preparing α-aluminum hydride by electrochemical catalytic deposition, comprising the following steps:

[0031] (1) Refining of sodium aluminum hydride: Take 750g of sodium aluminum hydride, add 1.5L of refined anhydrous ether, stir, then add 2L of unrefined anhydrous ether, continue stirring for 3min, then add 2.0L of unrefined toluene, stir 15min, stand still for 12h; filter the mixed solution after standing still under reduced pressure, carry out atmospheric distillation at 120°C for the filtrate, distill off the solvent and recover it for later use, then filter the distillation product with suction, and put it under the condition of vacuum degree of 380mmHg and 60°C Dry for 3.5h to obtain refined sodium aluminum hydride.

[0032] (2) Preparation of α-aluminum trihydride by electrochemical catalysis: get the refined sodium aluminum hydride obtained in step (1) and dissolve it in ether, carry out vacuum distillation to form electrolyte, and the concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com