Flexible substrate repair structure, manufacturing method, and detection and repairing method

A technology of flexible substrates and manufacturing methods, applied in semiconductor/solid-state device manufacturing, circuit bendable/stretchable parts, circuits, etc. Waste and other problems, to achieve the effect of reducing manufacturing costs, good adhesion, and reducing color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

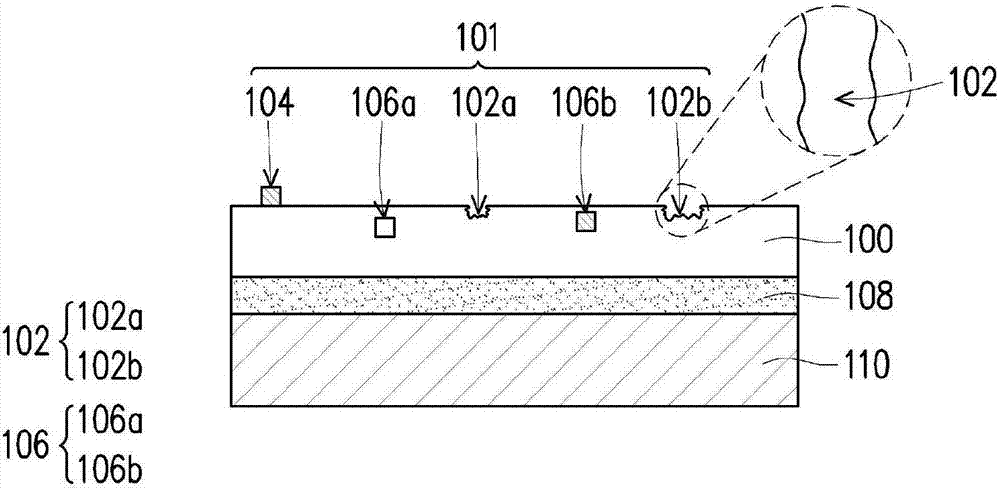

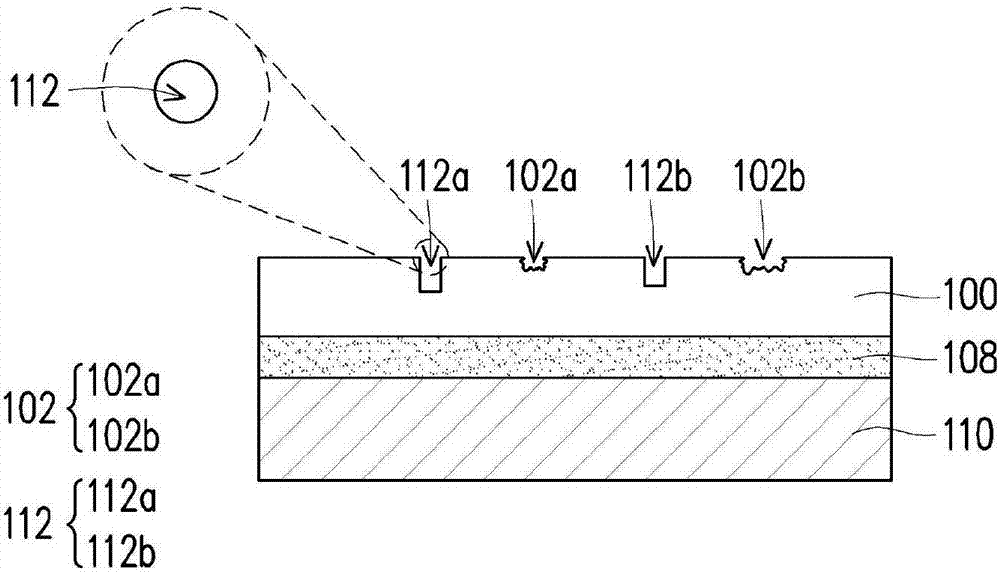

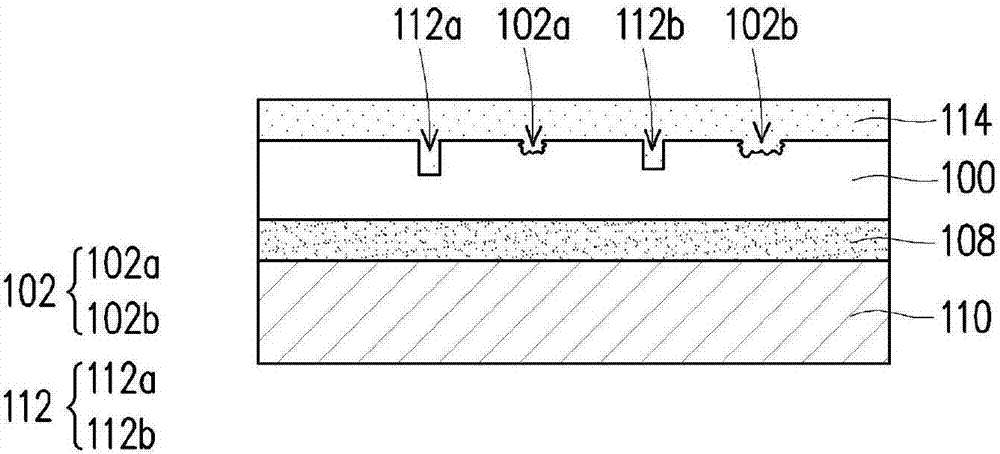

[0048] Please also refer to Figure 1A and figure 2 , The method for detecting and repairing a flexible substrate in this embodiment includes the following steps. Step S200 is performed to provide a flexible substrate 100 . The material of the flexible substrate 100 is, for example, polyimide (Polyimide; PI), polymethylmethacrylate (Polymethylmethacrylate; PMMA), polycarbonate (Polycarbonate; PC), polyethersulfone (Polyethersulfone; PES), polyamide (polyamide; PA), polynorbornene (polynorbornene; PNB), polyethylene terephthalate (polyethylene terephthalate; PET), polyether ether ketone (Polyether etherketone; PEEK), polyethylene naphthalate ( polyethylene naphthalate; PEN), polyethyleneimine (Polyethyleneimine; PEI) or a combination thereof.

[0049]In some embodiments, the flexible substrate 100 is formed on a rigid carrier 110 , and a de-bonding layer 108 has been formed on the rigid carrier 110 . In addition, the release layer 108 of a suitable material can be selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com