A Synthetic Method of Three-dimensional Radial Sn-Ni Alloy Loaded Platinum Nanoparticles Composite

A technology of tin-nickel alloy and composite materials, which is applied in the field of synthesis of three-dimensional radial tin-nickel alloy-loaded platinum nanoparticle composite materials, can solve the problem of expensive Pt, limited resource reserves, cost, electrode activity and stability that are difficult to meet fuel cells, etc. problems, to achieve convenient and concise product processing, high purity, and good catalytic effect of methanol oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

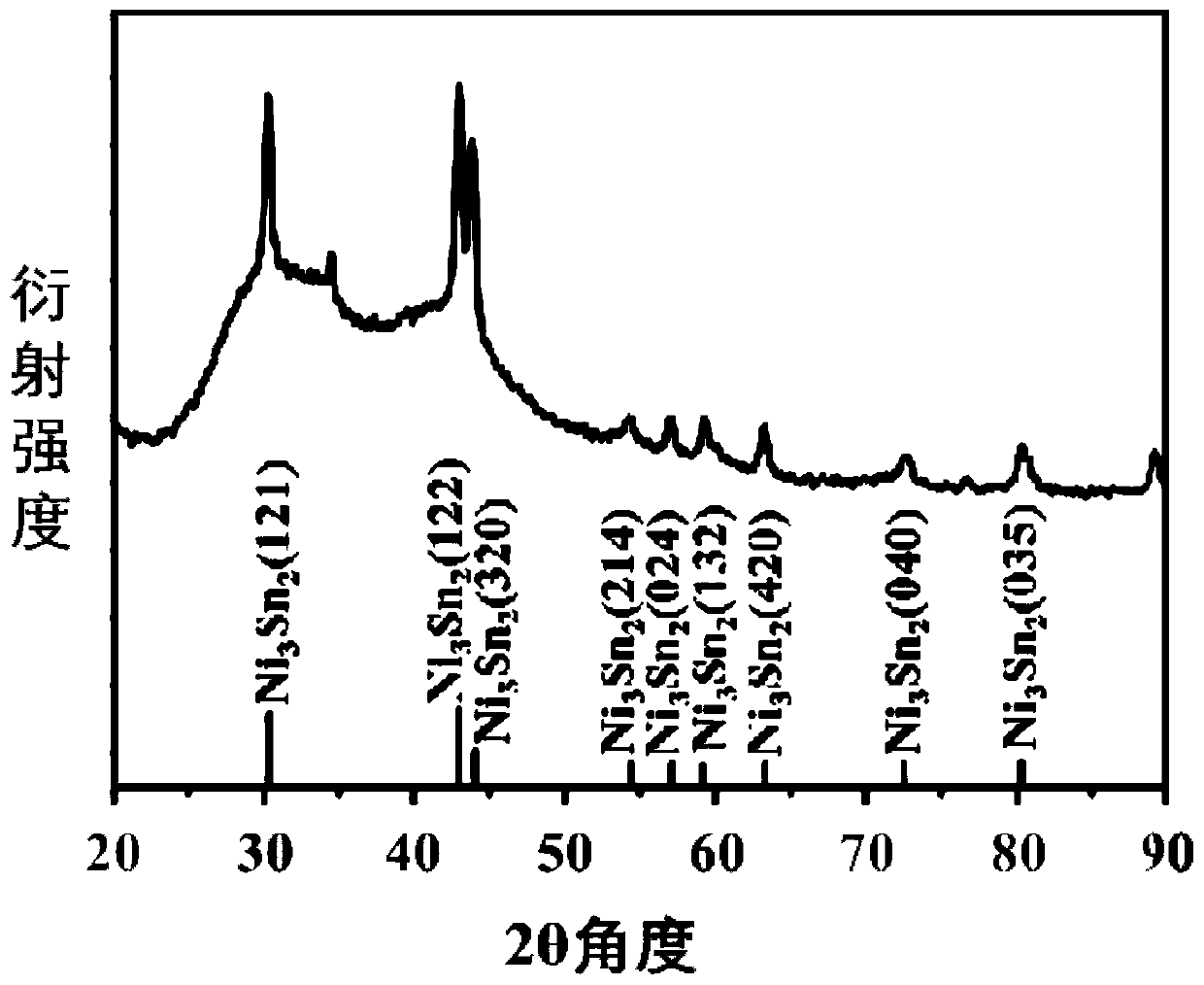

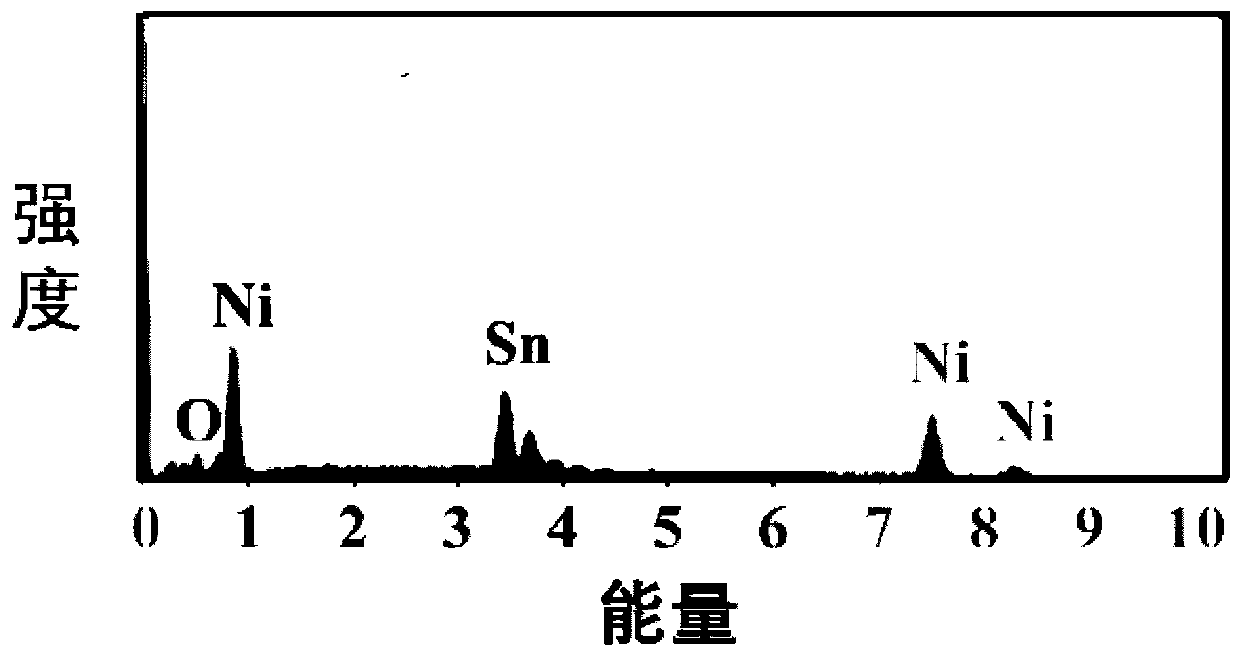

Embodiment 1

[0033] The first step, accurately weigh 0.0338g SnCl 2 2H 2 O, prepare 100mL solution with ethylene glycol, the concentration is 1.5mmol / L, accurately weigh 0.0357g NiCl 2 ·6H 2 O, prepare 100mL solution with ethylene glycol, the concentration is 1.5mmol / L, take the prepared 1.5mmol / L SnCl 2 2H 2 O and NiCl 2 ·6H 2 Put 5 mL of each ethylene glycol solution of O in a 30 mL reaction kettle, add 0.03 g of hexadecylamine and 2 mL of deionized water, and stir for 1 h.

[0034] In the second step, NaOH solution and 200 uL hydrazine hydrate were added to the reaction kettle, and after stirring evenly, the reaction kettle was put into an oven at 200° C. for 8 hours.

[0035] In the third step, the product is collected after the reaction, centrifuged, washed alternately with absolute ethanol and deionized water for several times, and dried in a vacuum oven to obtain a three-dimensional radial tin-nickel alloy.

[0036] In the fourth step, 1.0 mg of the three-dimensional radial t...

Embodiment 2

[0042] The first step, accurately weigh 0.0338g SnCl 2 2H 2O, prepare 100mL solution with ethylene glycol, the concentration is 1.5mmol / L, accurately weigh 0.0357g NiCl 2 ·6H 2 O, prepare 100mL solution with ethylene glycol, the concentration is 1.5mmol / L, take the prepared 1.5mmol / L SnCl 2 2H 2 O and NiCl 2 ·6H 2 Put 5 mL of each ethylene glycol solution of O in a 30 mL reaction kettle, add 0.03 g of hexadecylamine and 2 mL of deionized water, and stir for 1 h.

[0043] In the second step, NaOH solution and 200 uL hydrazine hydrate were added to the reaction kettle, and after stirring evenly, the reaction kettle was put into an oven at 200° C. for 4 hours.

[0044] In the third step, the product is collected after the reaction, centrifuged, washed alternately with absolute ethanol and deionized water for several times, and dried in a vacuum oven to obtain a three-dimensional radial tin-nickel alloy.

[0045] In the fourth step, 1.0 mg of the three-dimensional radial ti...

Embodiment 3

[0051] The first step, accurately weigh 0.0338g SnCl 2 2H 2 O, prepare 100mL solution with ethylene glycol, the concentration is 1.5mmol / L, accurately weigh 0.0357g NiCl 2 ·6H 2 O, prepare 100mL solution with ethylene glycol, the concentration is 1.5mmol / L, take the prepared 1.5mmol / L SnCl 2 2H 2 O and NiCl 2 ·6H 2 Put 5 mL of each ethylene glycol solution of O in a 30 mL reaction kettle, add 0.03 g of hexadecylamine and 2 mL of deionized water, and stir for 1 h.

[0052] In the second step, NaOH solution and 200 uL hydrazine hydrate were added to the reaction kettle, and after stirring evenly, the reaction kettle was put into an oven at 200° C. for 12 hours.

[0053] In the third step, the product is collected after the reaction, centrifuged, washed alternately with absolute ethanol and deionized water for several times, and dried in a vacuum oven to obtain a three-dimensional radial tin-nickel alloy.

[0054] In the fourth step, 1.0 mg of the three-dimensional radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com