Binary metal sulfide/carbon nitride composite photocatalytic material and preparation method thereof

A composite photocatalysis, binary metal technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high cost and limited development, and achieve low synthesis cost, easy storage, Excellent Visible Light Photocatalytic Decomposition of Water for Hydrogen Production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

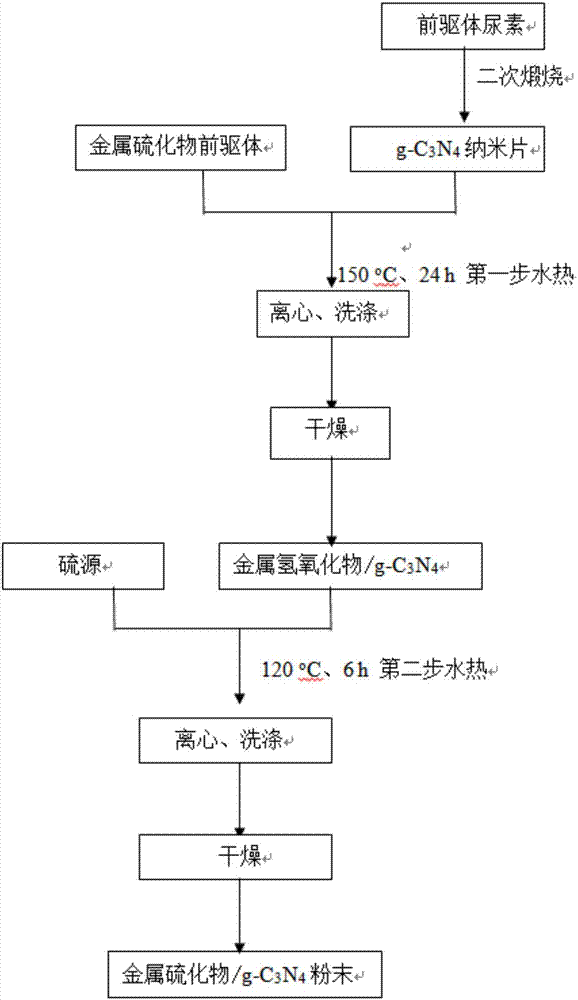

[0037] refer to figure 1 , Take a certain amount of urea and put it in an alumina crucible, cover it and place it in a muffle furnace, heat it to 550°C at a heating rate of 5°C / min and keep it at this temperature for 2h. When the temperature dropped to room temperature, the obtained solid was ground into powder, and then 0.1 g of the above-prepared powder was placed in a muffle furnace for the second temperature-programmed calcination, and heated to 420 °C at a heating rate of 5 °C / min. And keep at this temperature for 2 hours, then raise the temperature to 600°C at a heating rate of 5°C / min and hold for 3h. When the temperature drops to room temperature, the obtained light yellow powder is g-C 3 N 4 Nanosheets. Take 0.145mL of 0.05mol / L ferric nitrate solution, 1.45mL of 0.05mol / L nickel chloride solution, 5.6mL of 0.025mol / L urea solution, and 2mL of 0.0005mol / L trisodium citrate solution in a beaker, add 70.8mL of water, stirred for 10min, then take 1g of g-C 3 N 4 The...

Embodiment 2

[0039] Take a certain amount of urea in an alumina crucible, cover it and place it in a muffle furnace, heat it to 550°C at a heating rate of 5°C / min and keep it at this temperature for 2h. When the temperature dropped to room temperature, the obtained solid was ground into powder, and then 0.1 g of the above-prepared powder was placed in a muffle furnace for the second temperature-programmed calcination, and heated to 420 °C at a heating rate of 5 °C per minute And keep it at this temperature for 2 hours, then raise the temperature to 600 ℃ at a rate of 5 ℃ / min and keep it for 3 hours. When the temperature drops to room temperature, the obtained light yellow powder is g-C 3 N 4 Nanosheets. Take 0.145mL of 0.1mol / L ferric nitrate solution, 1.45mL of 0.1mol / L nickel chloride solution, 5.6mL of 0.05mol / L urea solution, and 2mL of 0.001mol / L trisodium citrate solution in a beaker, add 70.8mL of water, stirred for 10min, then take 1g of g-C 3 N 4 The nanosheets were ultrason...

Embodiment 3

[0044] Take a certain amount of urea in an alumina crucible, cover it and place it in a muffle furnace, heat it to 550°C at a heating rate of 5°C / min and keep it at this temperature for 2h. When the temperature dropped to room temperature, the obtained solid was ground into powder, and then 0.1 g of the above-prepared powder was placed in a muffle furnace for the second temperature-programmed calcination, and heated to 420 °C at a heating rate of 5 °C / min. And keep it at this temperature for 2 hours, then raise the temperature to 600 ℃ at a rate of 5 ℃ / min and keep it for 3 hours. When the temperature drops to room temperature, the obtained light yellow powder is g-C 3 N 4 Nanosheets. Take 0.145mL of 0.25mol / L ferric nitrate solution, 1.45mL of 0.25mol / L nickel chloride solution, 5.6mL of 0.125mol / L urea solution, and 2mL of 0.0025mol / L trisodium citrate solution in a beaker, add 70.8mL of water, stirred for 10min, then take 1g of g-C 3 N 4 The nanosheets were ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com