Reinforced composite membranes and method for manufacturing the same

A technology for enhancing composite and composite membranes, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of long engineering time, limited thin film, difficult large-scale manufacturing, etc., to save production time and production. Cost, improvement in mechanical strength, and the effect of realizing large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

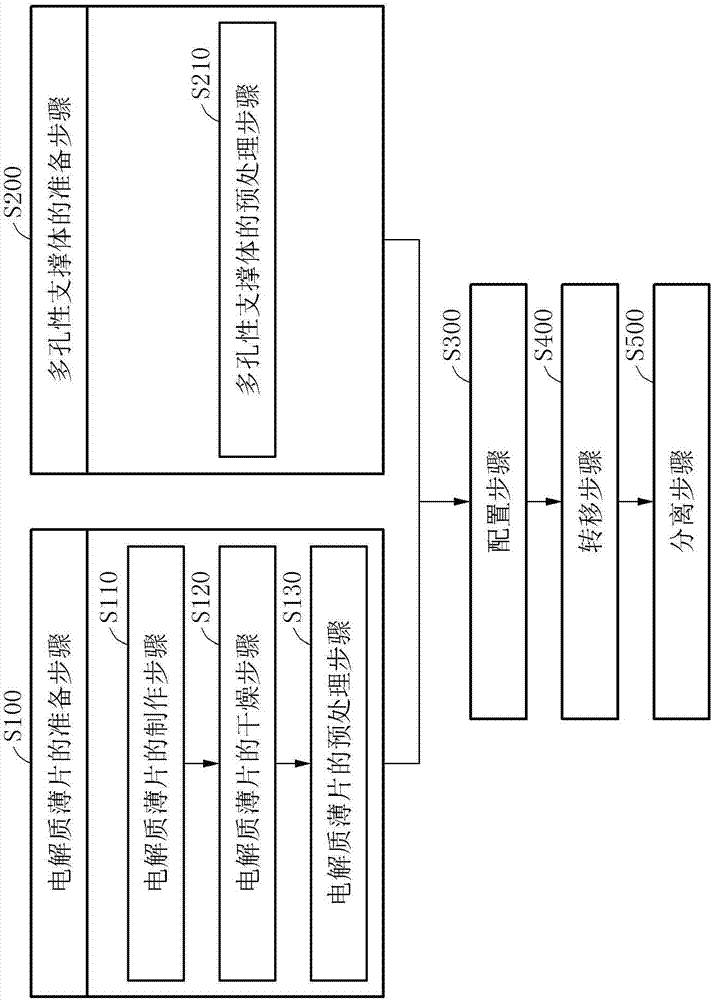

[0059] The invention relates to a method for preparing a reinforced composite membrane. The preparation method can improve the interface stability between electrolytes or reinforced supports, improve the penetration force in the reinforced support body of the electrolyte, and provide reinforced composite membranes with a high electrolyte impregnation rate. membrane. The preparation method refers to Figure 2 to Figure 6 Be explained.

[0060] According to one embodiment of the present invention, figure 2 It is a flow chart exemplarily showing a method for preparing a reinforced composite membrane according to an embodiment of the present invention. exist figure 2 Among them, the preparation method may include: preparation step S100 of the electrolyte sheet; preparation step S200 of the porous support; configuration step S300; transfer step S400 and separation step S500.

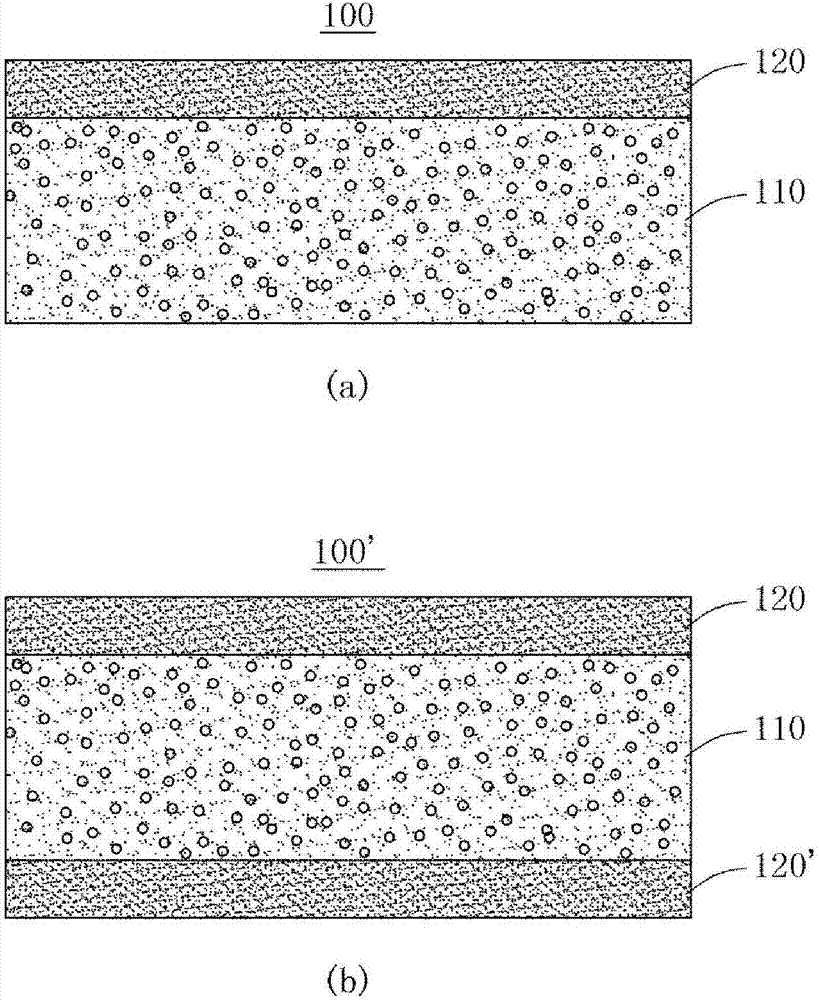

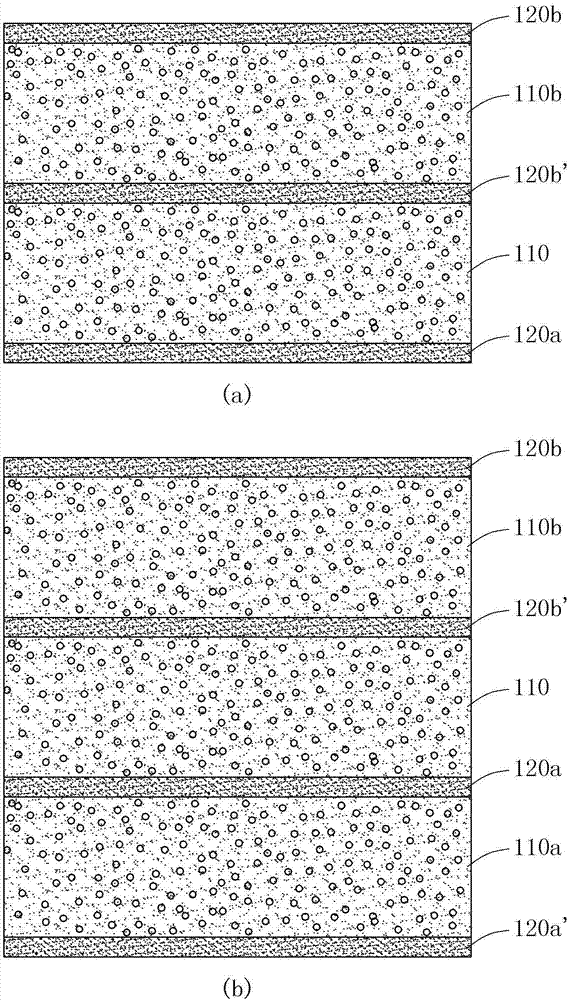

[0061] refer to image 3 Be explained, image 3 It exemplarily shows the preparation process of th...

Embodiment 1-4

[0090] As shown in Table 1, after thinly spraying 0.3ml of butanol on the electrolyte membrane of the electrolyte sheets of production examples 1 and 2, a pressure of 3 bar was applied at 80-100°C by a roller press, thereby Three-layer reinforced composite membranes in which the electrolyte membranes of Production Examples 1 and 2 were formed were prepared on both sides of the pretreated porous supports of Production Examples 3 and 4. For the prepared reinforced composite membrane, the solvent was removed at a temperature of 70° C. for 8 hours to obtain a reinforced composite membrane with a thickness of 20±5 μm (Table 2).

[0091] 【Table 1】

[0092]

[0093] 【Table 2】

[0094] Thickness of reinforced composite film (μm) Example 1 21 Example 2 19 Example 3 20 Example 4 22

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com