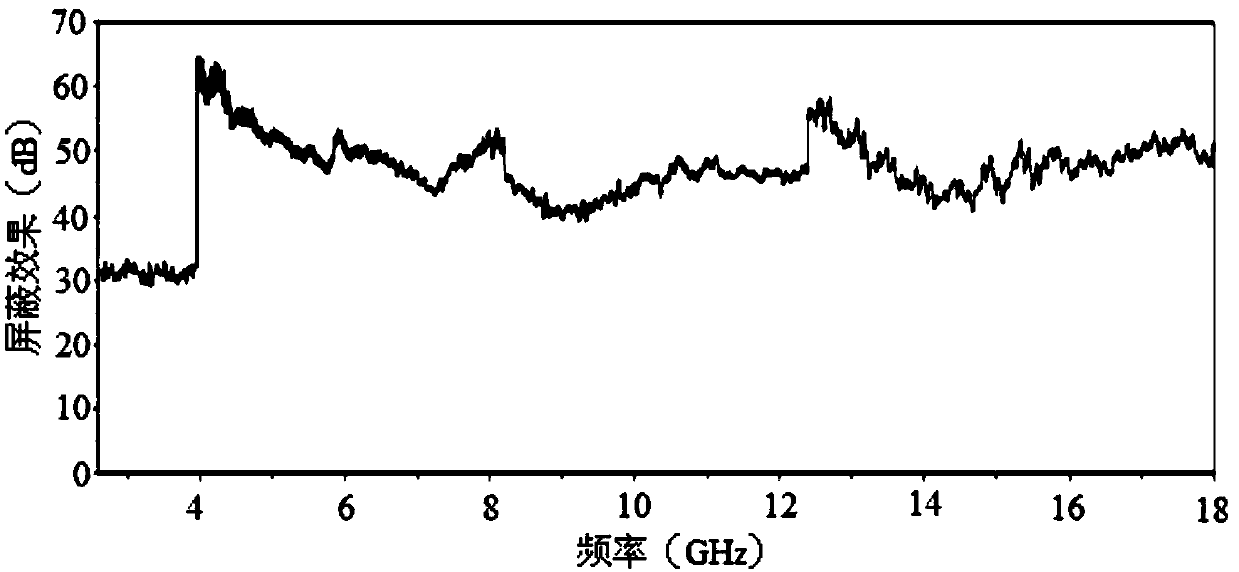

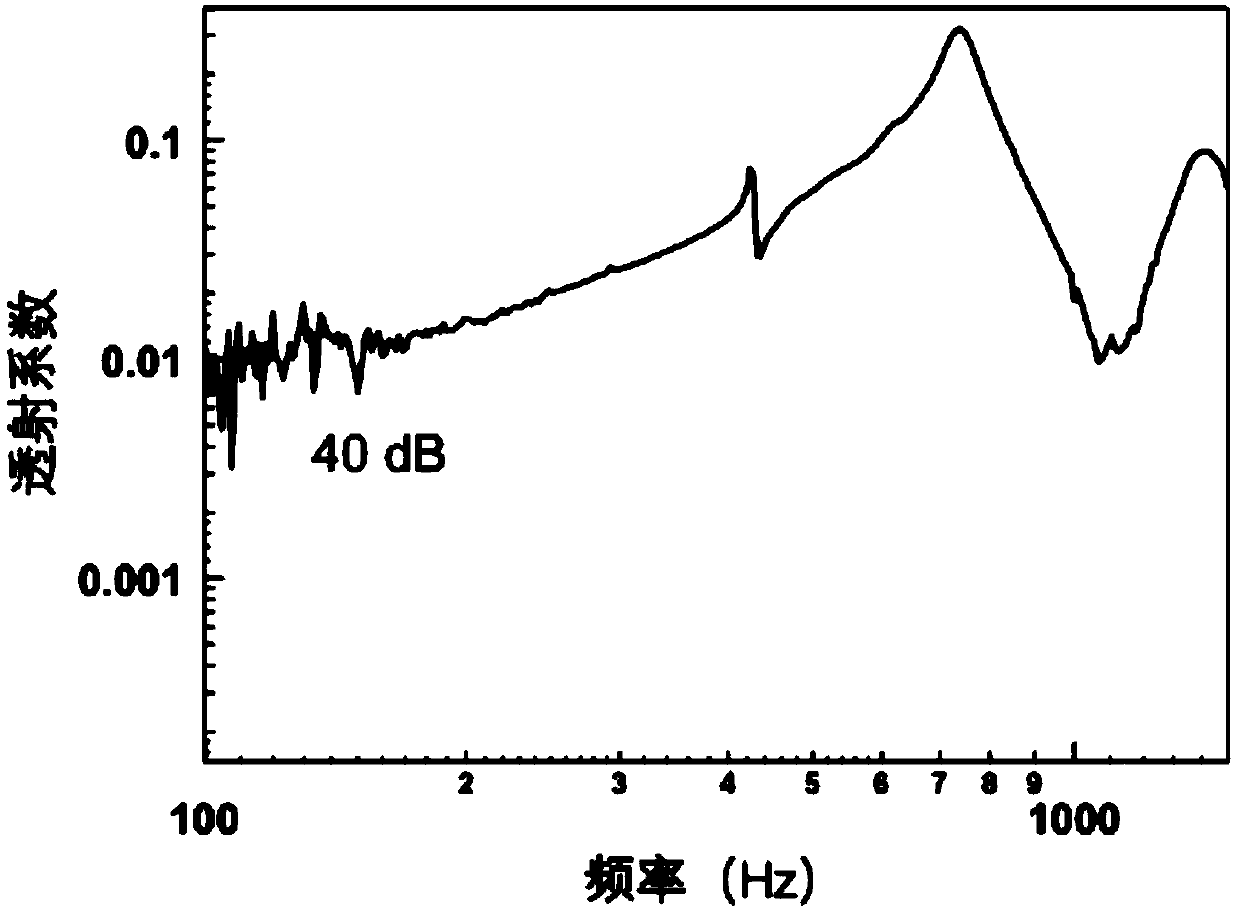

A preparation method of double-functional graphene paper that takes into account both sound insulation and electromagnetic shielding

A graphene paper, electromagnetic shielding technology, applied in graphene, chemical instruments and methods, nano-carbon and other directions, can solve the problems of complex preparation process, single performance, product size limited by equipment, etc., to achieve simple process, electrical conductivity and thermal conductivity. Excellent and promising results for a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Specific implementation mode one: a kind of preparation method that considers sound insulation and electromagnetic shielding bifunctional graphene paper described in this implementation mode is specifically carried out according to the following steps:

[0029] 1. Synthesis of graphene oxide: Add 5g of natural flake graphite to 400mL of sulfuric acid and phosphoric acid mixed acid to prepare a mixture. Stir the mixture for 30min at a stirring speed of 450r / min, and then add 5 to the stirred mixture. Subequal amounts of potassium permanganate were added at equal time intervals (the time interval was 5 minutes) to obtain the mixture after the addition of potassium permanganate, and then in a water bath at a temperature of 50°C, stirring at a constant temperature of 450r / min and a stirring speed of 6h, Then add ice water, and add hydrogen peroxide with a mass fraction of 40% to the ice water to obtain a suspension, suction filter, centrifugal washing, and dry at 80° C. for ...

specific Embodiment approach 2

[0042] Specific embodiment two: a kind of preparation method that considers sound insulation and electromagnetic shielding dual-function graphene paper described in this embodiment is specifically carried out according to the following steps:

[0043] 1. Synthesis of graphene oxide: add 10g of natural flake graphite to 300mL of sulfuric acid and phosphoric acid mixed acid to prepare a mixture, stir the mixture for 30min at a stirring speed of 700r / min, and then divide 6 into the stirred mixture Subequal amounts of potassium permanganate were added at equal time intervals (the time interval was 10 min) to obtain the mixture after the addition of potassium permanganate, and then in a water bath at a temperature of 60 ° C, stirred at a constant temperature of 550 r / min and a stirring speed of 8 h, Then add ice water, and add hydrogen peroxide with a mass fraction of 40% to the ice water, bright yellow to obtain a suspension, suction filter, centrifugal washing, and dry at 80° C. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com