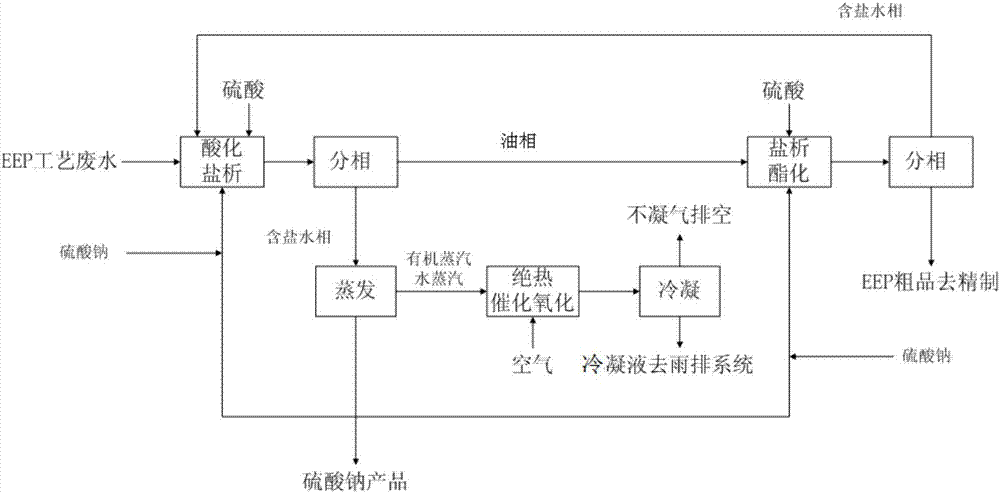

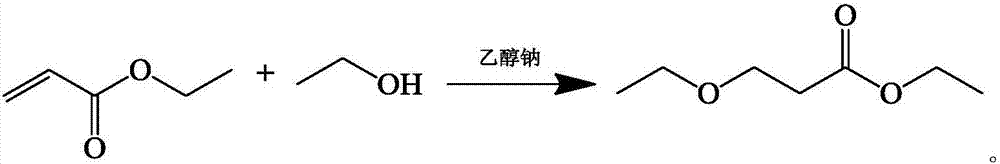

Recycling and purifying treatment method of sodium ethoxypropionate-containing wastewater

A technology of sodium ethoxypropionate and purification treatment, which is applied in the directions of oxidized water/sewage treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of unstable membrane performance, difficulty in meeting discharge standards, cumbersome processes, etc. To achieve the effect of resource reuse and purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The concentration of EEP in the wastewater containing sodium ethoxy propionate produced during the EEP production process is 5 wt%, the concentration of ethanol is 20 wt%, the concentration of 3-ethoxy sodium propionate is 10 wt%, and the rest is water. The above-mentioned waste water containing ethoxypropionate sodium salt is used as a resource and purified, and the steps are as follows:

[0038] Acidification and salting out: Take 1000g of the above process wastewater as a raw material and place it in an acidification and salting out kettle. After adjusting the pH of the wastewater to 3 with 35.7g of concentrated sulfuric acid (concentration 98wt%), add 400g of anhydrous sodium sulfate to stir and salt out. After stirring for 15 minutes, stand still and separate the phases to obtain 1100.7g of the first salt-containing phase and 328.9g of oil phase. In the oil phase, there is 50g of EEP, 194.6g of ethanol, and 84.3g of ethoxypropionic acid.

[0039] Salt-out esterific...

Embodiment 2

[0043] The concentration of EEP in the wastewater containing sodium ethoxypropionate produced during the production of EEP is 2wt%, the concentration of ethanol is 22wt%, the concentration of 3-ethoxysodium propionate is 13wt%, and the rest is water. The above-mentioned waste water containing ethoxypropionate sodium salt is used as a resource and purified, and the steps are as follows:

[0044] Acidification and salting-out: take 1000g of the above-mentioned wastewater process wastewater as a raw material and place it in an acidification and salting-out kettle, after adjusting the pH to 2 with 46.4g of concentrated sulfuric acid (concentration 98wt%), add 450g of anhydrous sodium sulfate to stir and salt-out, at 40°C After stirring for 15 minutes, stand still and separate the phases to obtain 955.9 g of the first salt-containing phase and 342.7 g of oil phase. In the oil phase, there are 20 g of EEP, 213.1 g of ethanol, and 109.6 g of ethoxypropionic acid.

[0045] Salting out...

Embodiment 3

[0049] In the wastewater containing sodium ethoxypropionate produced during the production of EEP, the concentration of EEP is 3wt%, the concentration of ethanol is 23wt%, the concentration of 3-ethoxysodium propionate is 11wt%, and the rest is water. The above-mentioned waste water containing ethoxypropionate sodium salt is used as a resource and purified, and the steps are as follows:

[0050] Acidification and salting out: Take 1000g of the above-mentioned process wastewater as a raw material and place it in an acidification and salting out kettle, adjust the pH to 3 with 39.3g of concentrated sulfuric acid (98wt%), add 280g of anhydrous sodium sulfate to stir and salt out, and stir at 50°C for 15min After standing still, the phases were separated to obtain 965.8g of the first salt-containing phase and 343.1g of the oil phase. In the oil phase, there was 30g of EEP, 220.4g of ethanol, and 92.7g of ethoxypropionic acid.

[0051] Salting out, esterification, and phase separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com