Self-stabilized carbon dioxide/ammonia water switch foam system

A foam system, carbon dioxide technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature resistance of foam, poor foam stability, insensitive switch, etc., and achieve simplified operation and good foaming. stability and foam stability, and the effect of a wide range of working environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment tests the CO of the foaming agent erucamide propyl-N,N-dimethyl tertiary amine 2 Response behavior and its foaming and foam stabilizing properties.

[0033] The composition of the foaming liquid is as follows:

[0034]

[0035]

[0036] experimental method:

[0037] (1) Weigh 5g of erucamidopropyl-N,N-dimethyl tertiary amine and mix it with 95g of deionized water, heat and stir in a water bath at 90°C, and inject 1L / min of CO into the mixture 2 , until a uniformly dispersed milky white dispersion is obtained. Weigh 10g of the dispersion and dilute it to a concentration of 0.5%, and feed CO at 0.4L / min 2 Pretreatment for 3 minutes to obtain CO 2 Pretreatment liquid, another 10g of dispersion liquid was weighed and diluted to 0.5% concentration, and N was passed through at 0.4L / min 2 Pretreatment for 3min to get N 2 Pretreatment solution.

[0038] (2) Measure 20ml of CO respectively 2 Pretreatment solution, N 2 Use Anton Paar MCR302 rheometer ...

Embodiment 2

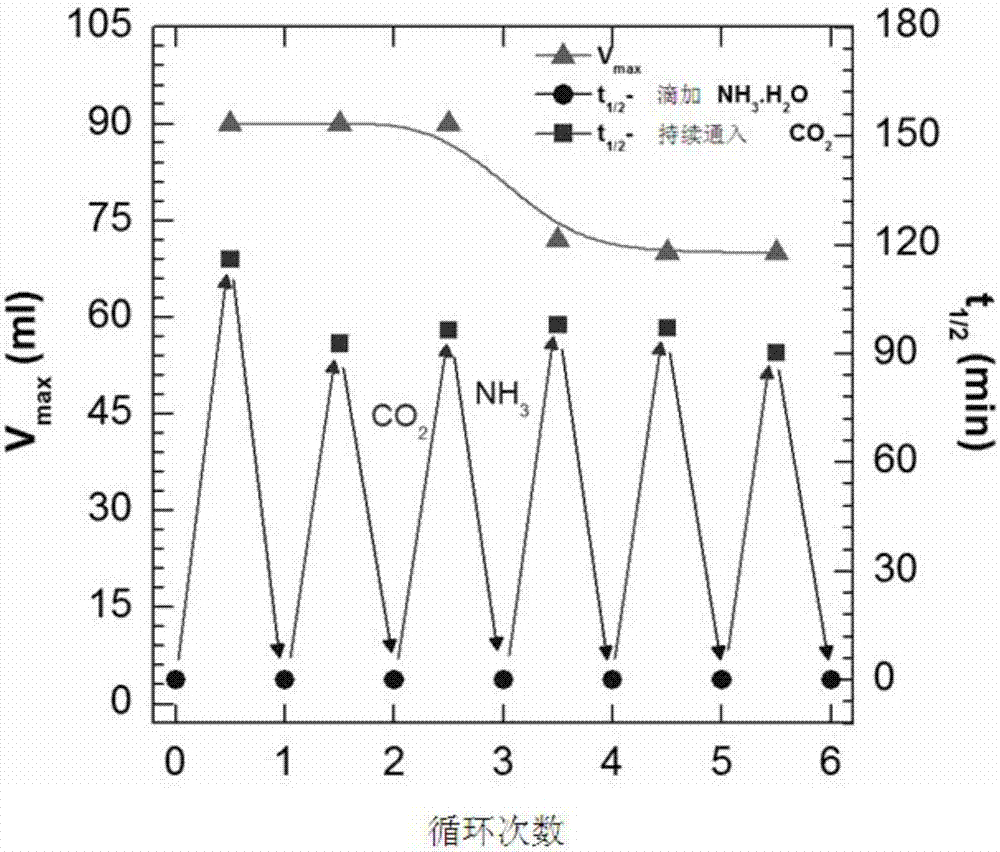

[0044] In this example, the foaming agent erucamide propyl-N,N-dimethyl tertiary amine and CO 2 On-off properties of the foam formed by the reaction.

[0045] The composition of the foaming liquid is as follows:

[0046]

[0047] experimental method:

[0048] (1) Weigh 5g of erucamidopropyl-N,N-dimethyl tertiary amine and mix it with 95g of deionized water, heat and stir in a water bath at 90°C, and inject 1L / min of CO into the mixture 2 , until a uniformly dispersed milky white dispersion is obtained. Weigh 10g of the dispersion and dilute to a mass concentration of 0.5%, then measure 100ml and inject it into the kettle of the high-temperature and high-pressure foam generator. Set the temperature of the instrument to 80°C, preheat at 80°C for 30 minutes, and then pass CO into the kettle 2 Until the pressure balance is 3MPa, then start the test, foam for 3min under high-speed stirring (1020r / min), record the maximum foaming volume V max and the foam half-life t 1 / 2 , ...

Embodiment 3

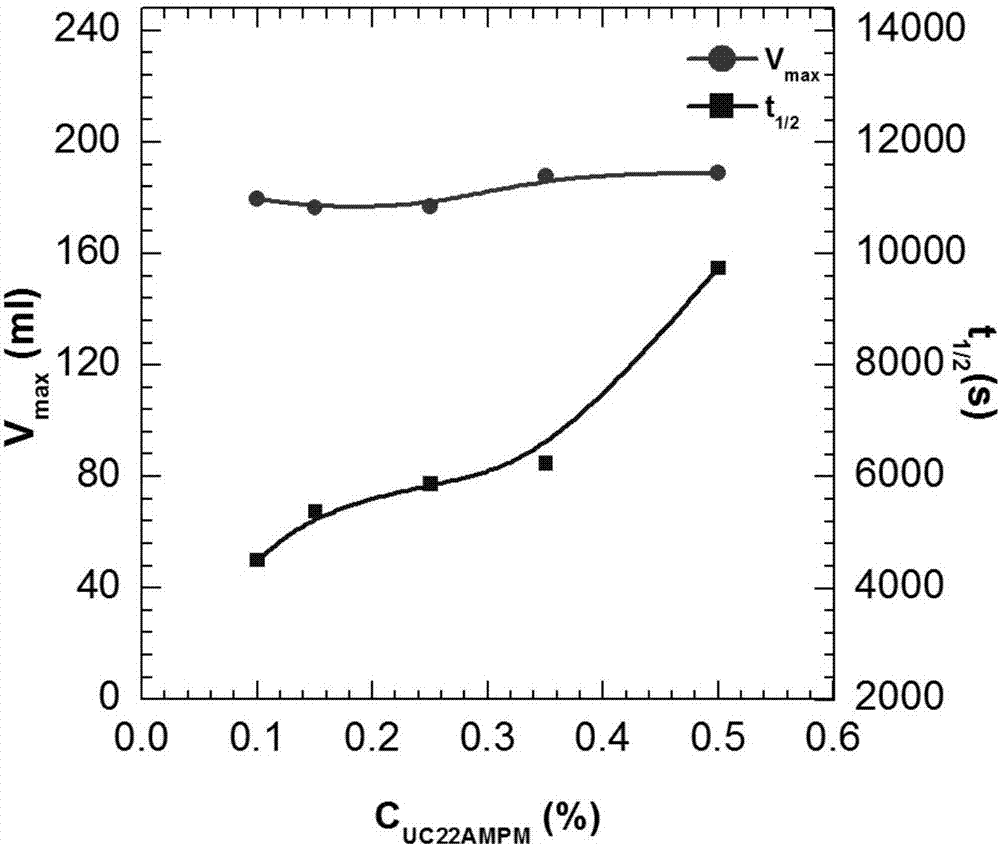

[0056] In this example, the effect of the concentration of the foaming agent erucamide propyl-N,N-dimethyl tertiary amine on the foam performance (foaming performance and foam stabilizing performance) was tested.

[0057] The composition of the foaming liquid is as follows:

[0058]

[0059] experimental method:

[0060] (1) Weigh 5g of erucamidopropyl-N,N-dimethyl tertiary amine and mix it with 95g of deionized water, heat and stir in a water bath at 90°C, and inject 1L / min of CO into the mixture 2 , until a uniformly dispersed milky white dispersion is obtained. A certain amount of dispersion liquid was weighed and diluted to 0.10%, 0.15%, 0.25%, 0.35% and 0.50% of the mass concentration of erucamide propyl-N,N-dimethyl tertiary amine (UC22AMPM). Take 100mL of the dispersion liquid of each concentration and pass through CO at 0.4L / min 2 Pretreatment for 3 minutes to form a pretreatment solution.

[0061] (2) Measure 20mL of pretreatment solution of each concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com