Calcium sulfosilicate sulfoaluminate cement and preparation method thereof

A technology of calcium sulfosilicate sulfoaluminate and cement, which is applied in cement production, clinker production, etc., can solve the problems of increasing energy consumption in the preparation of sulfur-containing calcium sulfoaluminate cement clinker, and achieve easy grinding Good performance, reduced CO2 emissions, and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Calcium sulfosilicate sulfoaluminate cement was prepared as follows:

[0033] A. Preparation of cement raw meal

[0034] Mix 71.39 parts by mass of limestone, 43.34 parts by mass of phosphogypsum, 6.22 parts by mass of kaolin, and 18.24 parts by mass of fly ash, and then grind the prepared raw meal through a 100-mesh sieve to obtain cement raw meal.

[0035] B. Preparation of cement clinker

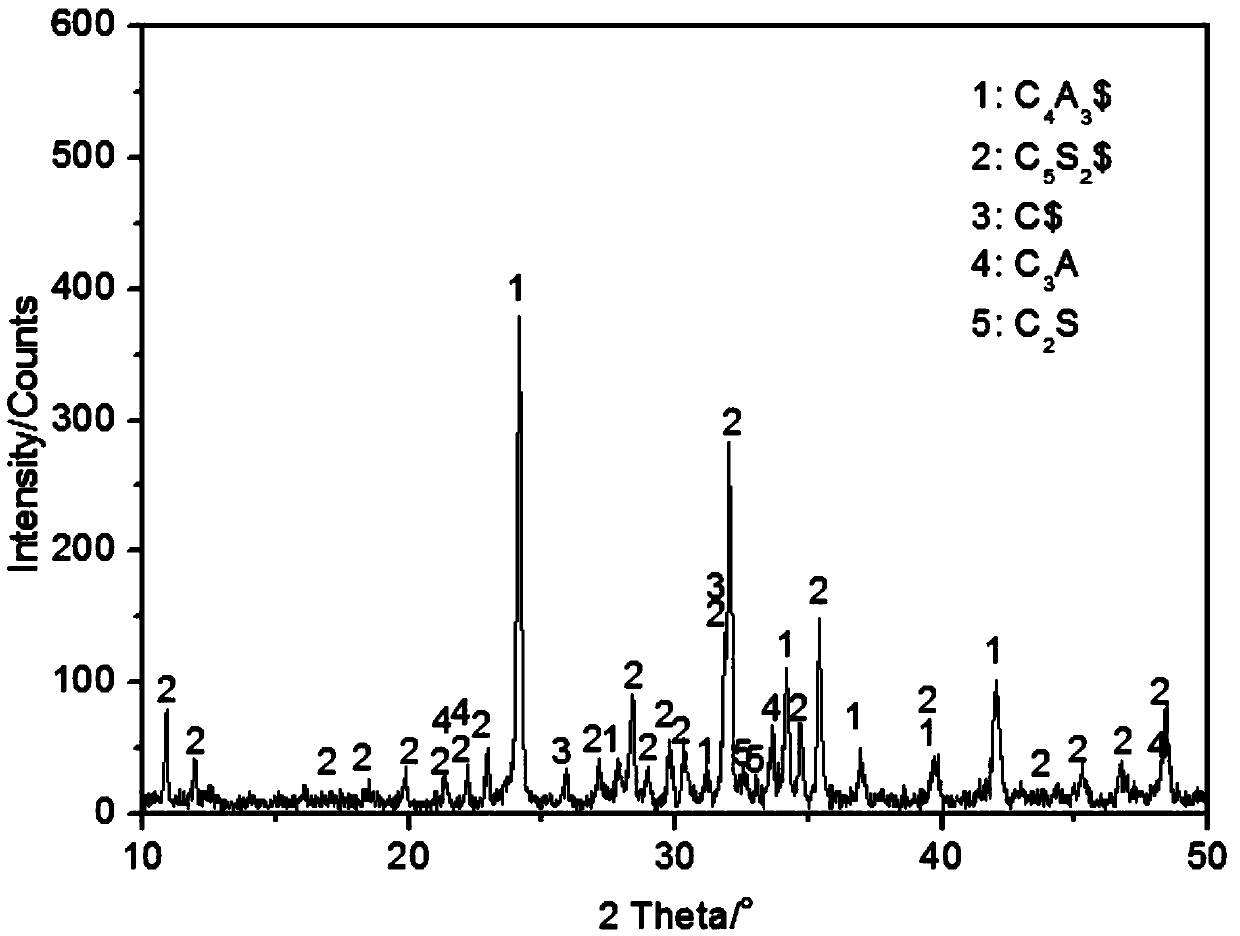

[0036] Put the raw material obtained in A into a high-temperature furnace for calcination, and the high-temperature furnace is raised from room temperature to 1130°C, and kept at 1130°C for 30 minutes, then the clinker is taken out of the high-temperature furnace and quenched in air to obtain calcium sulfosilicate Sulphoaluminate cement clinker, figure 1 It is the XRD spectrum of the cement clinker of this implementation. According to Rietveld quantitative analysis, the mineral composition of cement clinker is: C 4 A 3 $: 21.26%, C 5 $ 2 S: 60.41%, C 3 A: 8.05% C$: 7.79, C ...

Embodiment 2

[0038] Calcium sulfosilicate sulfoaluminate cement was prepared as follows:

[0039] A. Preparation of cement raw meal

[0040]Mix 67.64 parts by mass of limestone, 40.67 parts by mass of phosphogypsum, 38.84 parts by mass of bauxite, and 0.48 parts by mass of fly ash, and then grind the prepared raw meal through a 100-mesh sieve to obtain cement raw meal.

[0041] B. Preparation of cement clinker

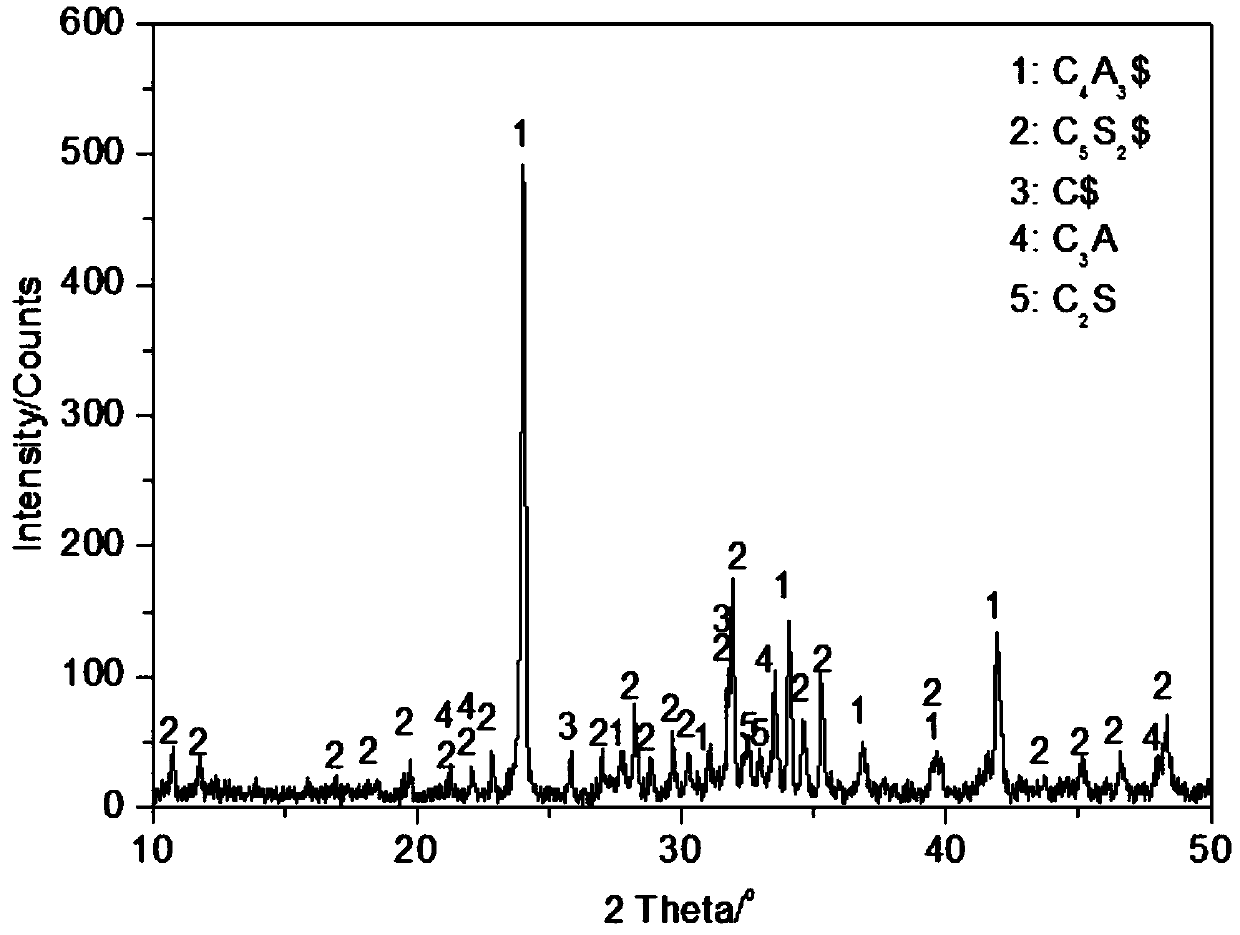

[0042] The raw material obtained in A is calcined in a high-temperature furnace, and the high-temperature furnace is raised from room temperature to 1130°C, and kept at 1130°C for 60 minutes, and then the clinker is taken out of the high-temperature furnace and quenched in air to obtain calcium sulfosilicate Sulphoaluminate cement clinker, figure 2 It is the XRD spectrum of the cement clinker of this implementation. According to Rietveld quantitative analysis, the mineral composition of cement clinker is: C 4 A 3 $: 36.21%, C 5 $ 2 S: 42.00%, C 3 A: 9.21 C$: 5.83%, C 2 S:...

Embodiment 3

[0044] Calcium sulfosilicate sulfoaluminate cement was prepared as follows:

[0045] A. Preparation of cement raw meal

[0046] Mix 67.64 parts by mass of limestone, 40.67 parts by mass of fluorogypsum, 38.84 parts by mass of bauxite, and 0.48 parts by mass of fly ash, and then grind the prepared raw meal through a 100-mesh sieve to obtain cement raw meal.

[0047] B. Preparation of cement clinker

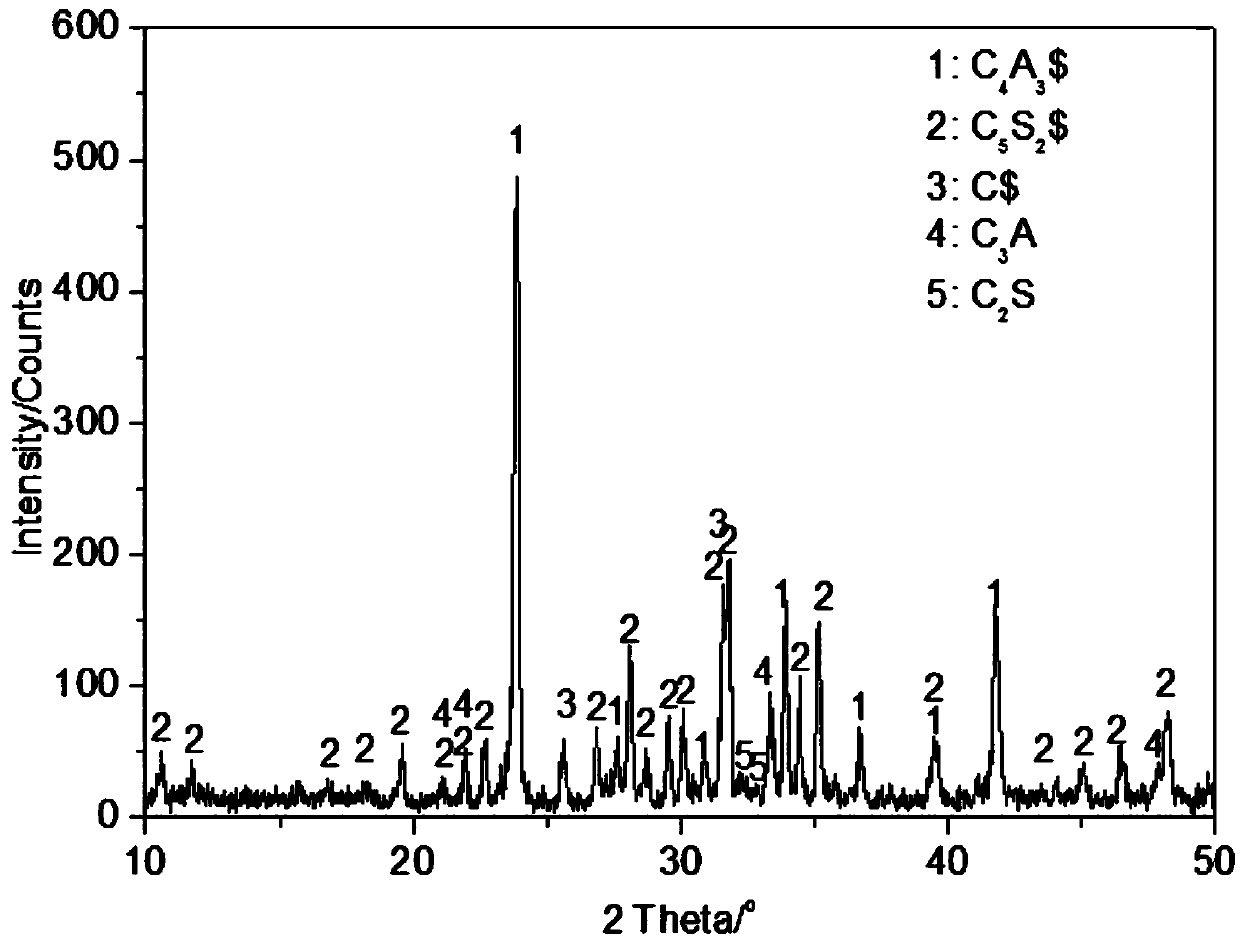

[0048] Put the raw material obtained in A into a high-temperature furnace for calcination, and the high-temperature furnace is raised from room temperature to 1150°C, and kept at 1150°C for 60 minutes, then the clinker is taken out of the high-temperature furnace and quenched in air to obtain calcium sulfosilicate Sulphoaluminate cement clinker, image 3 It is the XRD spectrum of the cement clinker of this implementation. According to Rietveld quantitative analysis, the mineral composition of cement clinker is: C 4 A 3 $: 35.17%, C 5 $ 2 S: 45.58%, C 3 A: 10.02 C$: 8.79, C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com