An anti-condensation coating and a radiation terminal with the coating on its surface and an air-conditioning system

An anti-condensation coating and radiation terminal technology, applied in the field of coatings and anti-condensation coatings that reduce the dew point of water vapor on the surface of cold radiant panels, can solve problems such as high cost, increased actual energy consumption, and heat transfer effects, and achieve Enhanced hydrophobic performance, avoid condensation, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add a certain amount of polytetrafluoroethylene powder, fluorine-containing wax powder, fluorocarbon resin, methyl silicone oil, organic bentonite and BYK410 anti-sedimentation agent to the mixture of acetone, propylene glycol methyl ether acetate, xylene and cyclohexanone according to the 2; 2; 2; 1 in the mixed solvent, first disperse at high speed for 30 minutes, then use a ball mill to grind the mixture to a white slurry with a fineness of less than 35 microns, as component A. Then mix it with component B (moisture-curing polyurethane 7360) according to a certain proportion, and cure it at room temperature for 15 minutes before construction.

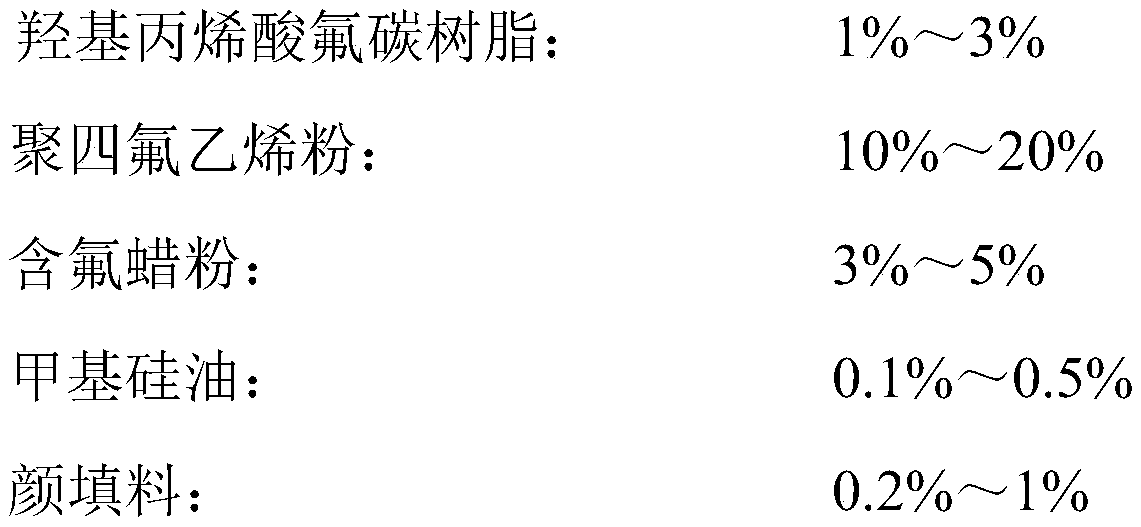

[0047] The composition ratio of the anti-condensation coating in this example is as follows:

[0048]

Embodiment 2

[0050] The anti-condensation coating preparation process of this example is the same as that of Example 1.

[0051] The composition ratio of the anti-condensation coating in this example is as follows:

[0052]

[0053]

Embodiment 3

[0055] The anti-condensation coating preparation process of this example is the same as that of Example 1.

[0056] The composition ratio of the anti-condensation coating in this example is as follows:

[0057]

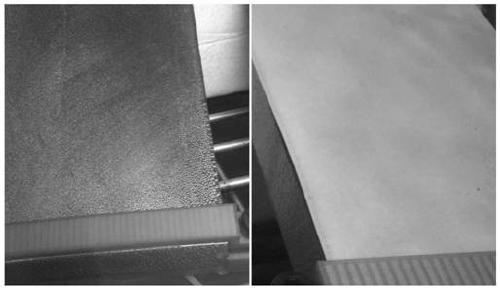

[0058] In order to better evaluate the effect of the anti-condensation coating of the present invention, the anti-condensation coating was coated on a tinplate sheet by spraying means to make a sample, and after being fully dried and cured at room temperature, an anti-condensation experiment was carried out. At the same time, the commonly used polyurethane varnish is applied on the tinplate sheet of the same specification as a control model. Place the two samples in a constant temperature and humidity chamber to investigate their anti-condensation performance. Such as figure 1 As shown, under the same conditions (the sample surface temperature is 18±0.2°C, the ambient temperature is 24.1±0.2°C, and the relative humidity is 79%), the dew condensation on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com