Slow aromatic polyelectrolyte microcapsule with casein-sodium alginate serving as compound wall materials and preparation method of microcapsule

A technology of sodium alginate and polyelectrolyte, which is applied in the fields of cosmetics, food and coatings, can solve problems such as complicated operation, and achieve the effects of simple experimental conditions, convenient operation and increased added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

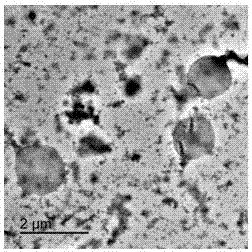

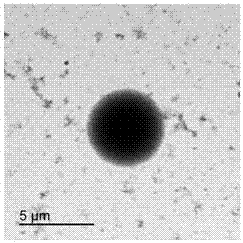

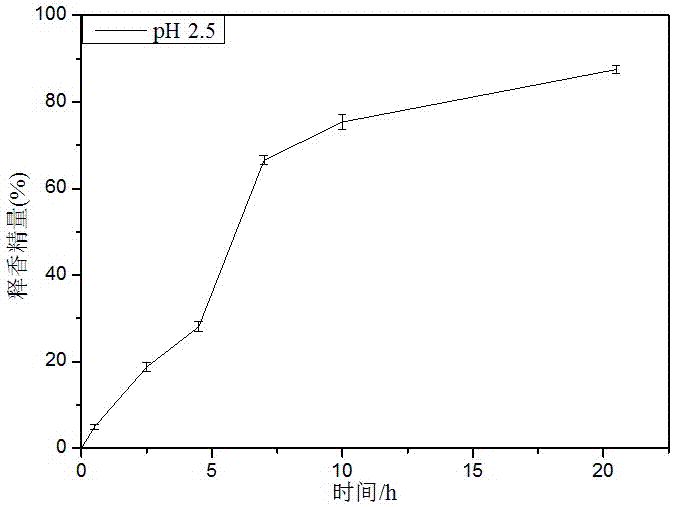

[0026] The preparation method of the fragrance-slowing polyelectrolyte microcapsule using casein-sodium alginate as the composite wall material involved in the present invention uses casein and sodium alginate as the wall material, essence as the core material, and obtains slow-flavoring polyelectrolyte microcapsules through a composite coacervation method. Fragrant casein-sodium alginate composite microcapsules. The prepared fragrance-sustaining polyelectrolyte microcapsules have a uniform spherical structure, and the diameter of the capsules is on the order of nanometers to micrometers, which effectively coats the essence. The inner wall material of the system is a natural polymer material, and there is no organic solvent, template and cross-linking agent, which avoids organic solvents and templates in traditional methods, and omits the cumbersome process of removing templates and solvents; the reaction conditions are mild, and it is easy to realize large-scale production ch...

Embodiment 1

[0038] Step 1: Preparation of Casein / Essence Mixture and Sodium Alginate Solution

[0039] Add 0.0165 g of casein powder (casein concentration is 0.33%, w / v) into the aqueous solution containing acid medium with a pH value of 2.5, and then add 0.1000 g of flavor powder (flavor concentration is 2.00%, w / v), allowed to mix well, and stirred overnight to obtain casein / flavor blend A. Dissolve 0.0835 g of sodium alginate in pure water (the concentration of sodium alginate is 1.67%, w / v), and stir overnight to obtain sodium alginate solution B.

[0040] Step 2: Preparation of fragrance-loaded slow-flavor casein-sodium alginate composite microcapsules

[0041] Place the casein / essence mixture A in step 1 in a water bath at 30°C for stirring at a speed of 13 rpm. During this process, start adding the sodium alginate solution B in step 1 dropwise until the addition is complete Afterwards, stirring was continued for 30 min to obtain fragrance-loaded slow-flavor casein-sodium alginate...

Embodiment 2

[0043] Step 1: Preparation of casein / essence mixture and sodium alginate solution

[0044] Add 0.0500 g of casein powder (concentration of casein is 1.00%, w / v) into an aqueous solution containing an acidic medium with a pH value of 2.5, and after it dissolves, add 0.1000 g of powdered essence (concentration of essence is 2.00%, w / v), allowed to mix well, and stirred overnight to obtain casein / flavor blend A. Dissolve 0.0500 g of sodium alginate in pure water (the concentration of sodium alginate is 1.00%, w / v), and stir overnight to obtain sodium alginate solution B.

[0045] Step 2: Preparation of fragrance-loaded slow-flavor casein-sodium alginate composite microcapsules

[0046] Place the casein / essence mixture A in step 1 in a water bath at 30°C for stirring at a speed of 13 rpm. During this process, start adding the sodium alginate solution B in step 1 dropwise until the addition is complete Afterwards, stirring was continued for 30 min to obtain fragrance-loaded slow-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com