Carbon-nano-tube composite microwave absorbing material and preparation method thereof

A carbon nanotube composite and wave-absorbing material technology, which is applied in the direction of carbon compounds, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of low purity, poor wave-absorbing performance, and stable environment Poor performance and other problems, to achieve the effect of high purity, light weight, and improved wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

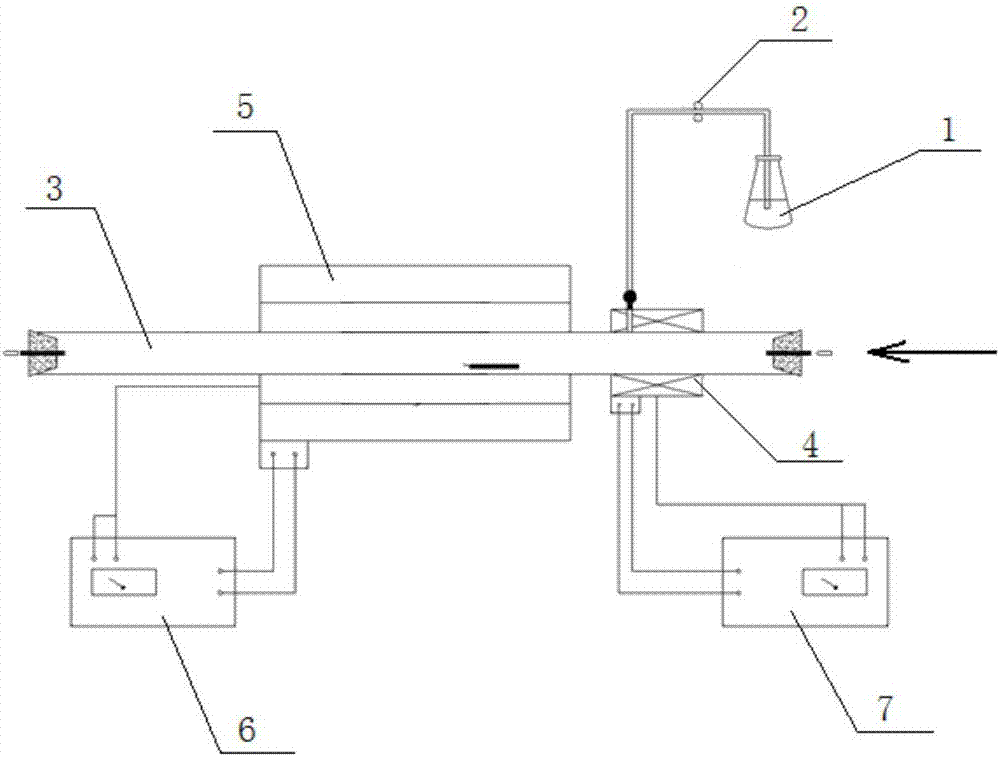

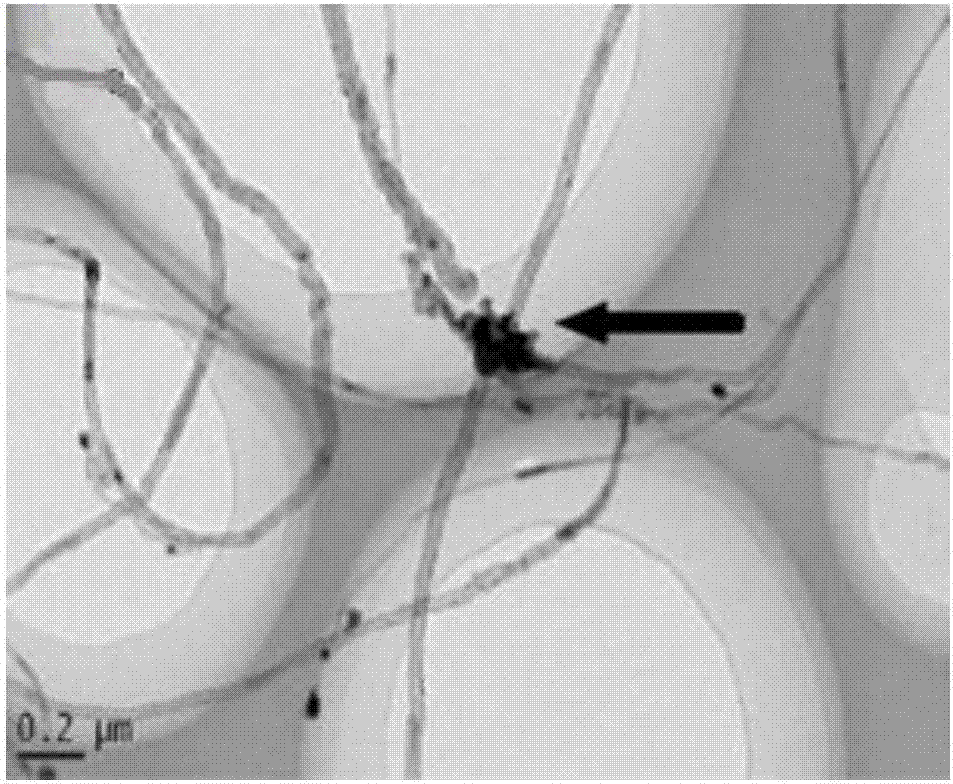

[0034] Such as figure 1 , figure 2 and Figure 4 As shown, a carbon nanotube composite wave-absorbing material, the material is a precursor solution 1 prepared by dissolving a catalyst in a liquid carbon source containing additives, and then made by a pressureless sintering method with carbon nanotubes as a matrix 1. Add iron particles and cobalt-nickel alloy particles to the inner wall of the carbon nanotubes, and a composite wave-absorbing material with rare earth compounds attached to the outer wall; the liquid carbon source is 1,2-dichloroethane solution, and the additive is Lanthanum nitrate, ethanol that promotes the dissolution of lanthanum nitrate is also added in the liquid carbon source; the volume ratio of the 1,2-dichloroethane solution to ethanol is 9:1, and the catalyst contains: 33.93wt% dichloromethane Iron, 33.19 wt% cobaltocene and 32.88 wt% nickelocene.

[0035] The rare earth compound is LaOCl (lanthanum oxychloride).

[0036] The component ratio of th...

Embodiment 2

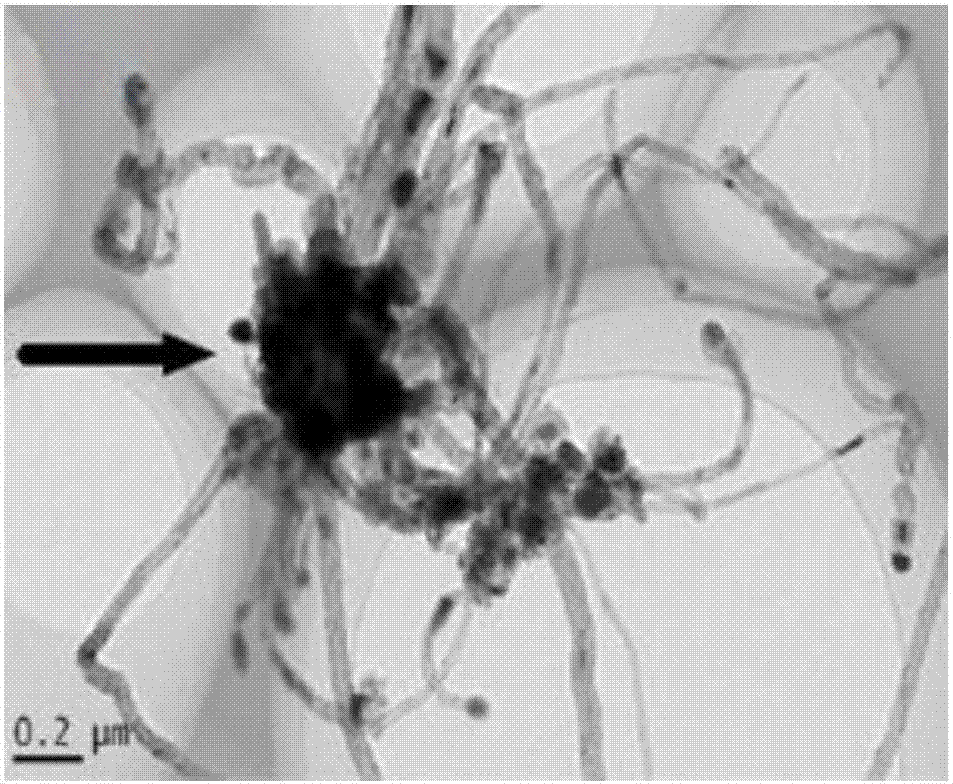

[0049] Such as figure 1 , image 3 and Figure 5 As shown, in this embodiment, the step (1) of the preparation method of the carbon nanotube composite wave-absorbing material is: dissolving 0.82g ferrocene, 0.80g ferrocene cobalt, and 0.78g ferrocene in 54ml of 1,2-dichloroethane and 6ml of ethanol in the mixed solution, mix well and then add 0.24g lanthanum nitrate to the mixed solution, after ultrasonic vibration evenly, make the precursor solution 1;

[0050] Other than that, other contents are the same as those in Embodiment 1.

Embodiment 3

[0052] In this embodiment, in the step (3) of the preparation method of the carbon nanotube composite wave-absorbing material, the temperature of the preheating zone 4 is kept at 220° C., and the reaction zone of the tube furnace 5 is heated so that The reaction zone temperature was maintained at 750°C.

[0053] Other than that, other contents are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com