Preparation method of composite magnesium oxide powder for dental alginate impression material

A technology of magnesium oxide powder and dental alginate, applied in the direction of dental impression materials, magnesium oxide, dental preparations, etc., can solve the problem that the activity of a single magnesium oxide product is not well controlled and the performance indicators of magnesium oxide powder The requirements are not uniform, and it is difficult to accurately control the solidification time of the final impression material, so as to achieve the effect of accurate target solidification time, easy demolding, and complete impression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

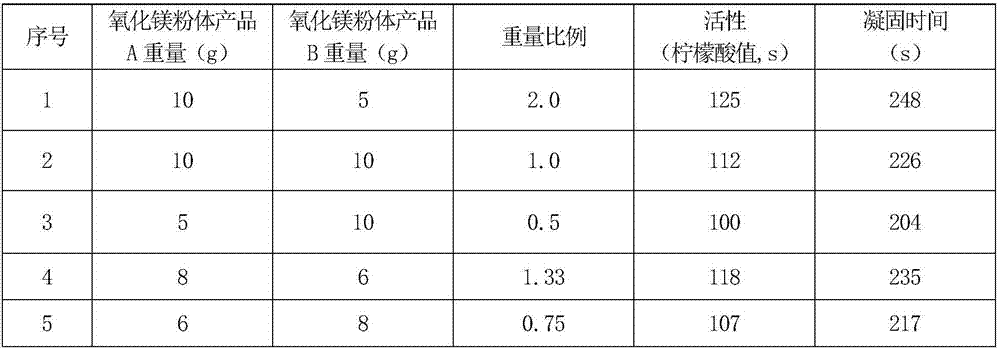

Embodiment 1

[0032] A preparation method of composite magnesium oxide powder for dental alginate impression material, comprising the following steps:

[0033] (1) Select magnesium hydroxide powder raw material, its main content Mg(OH) 2 97.3%, the impurity content CaO is 1.3%, SO 4 -2 0.3%, Cl - 0.10%, 9ppm for heavy metals, 2ppm for As, 0.08% for acid insolubles, 31.5% for loss on ignition, 1.8μm for laser particle size D50, and 96 for whiteness.

[0034] (2) Add the magnesium hydroxide powder raw material into the rotary kiln calciner, control the temperature range from the front part to the rear part in the rotary kiln to be 600°C to 625°C, and control the residence time of the material in the calciner to 1.4h . The magnesia powder after calcining was passed through a vibrating sieve to obtain a magnesia powder product A with 325 meshes passing through. The range of citric acid value for chemical detection of magnesium oxide A's reactivity is 145s, and the bulk density is 0.31g / cm...

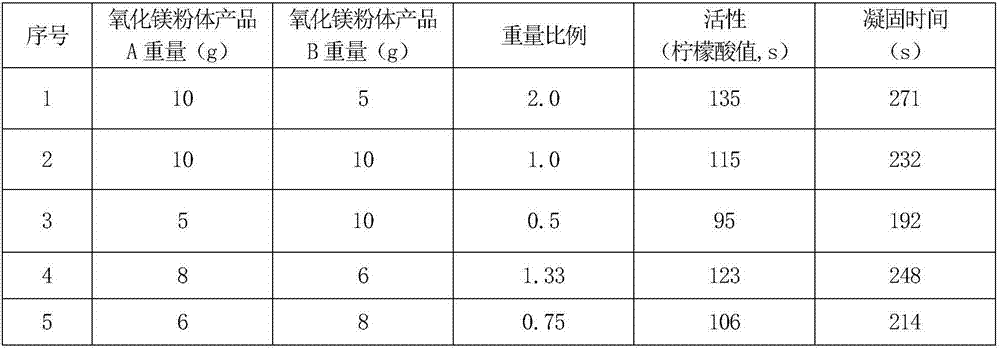

Embodiment 2

[0041] A preparation method of composite magnesium oxide powder for dental alginate impression material, specifically comprising the following steps:

[0042] (1) Select magnesium hydroxide powder raw material, its main content Mg(OH) 2 98.0%, the impurity content CaO is 1.0%, SO 4 -2 0.42%, Cl - 0.11%, 8ppm for heavy metals, 3ppm for As, 0.09% for acid insolubles, 32% for loss on ignition, 1.6μm for laser particle size D50, and 97 for whiteness.

[0043] (2) Add the magnesium hydroxide powder raw material into the rotary kiln calciner, control the temperature range from the front part to the rear part in the rotary kiln to be 700°C to 740°C, and control the residence time of the material in the calciner to 1.2h . The magnesia powder after calcining was passed through a vibrating sieve to obtain a magnesia powder product A with 325 meshes passing through. The range of citric acid value for chemical detection of magnesium oxide A reactivity is 175s, and the bulk density i...

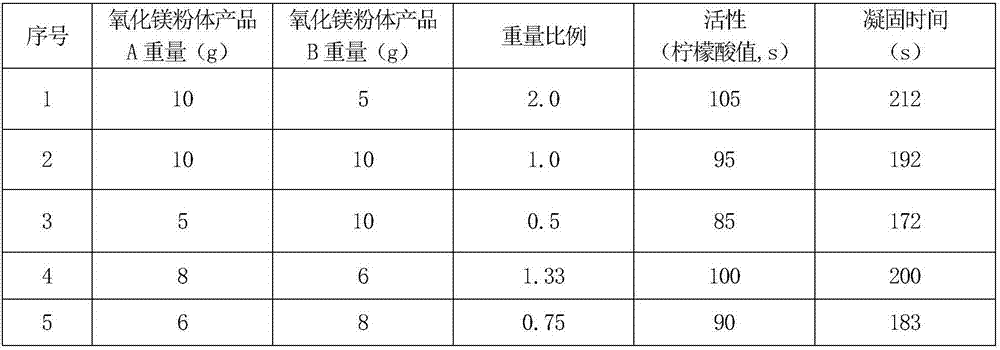

Embodiment 3

[0050] A preparation method of composite magnesium oxide powder for dental alginate impression material, comprising the following steps:

[0051] (1) Select magnesium hydroxide powder raw material, its main content Mg(OH) 2 99.0%, impurity content CaO is 0.5%, SO 4 -2 0.32%, Cl - 0.10%, 6ppm for heavy metals, 2ppm for As, 0.08% for acid insolubles, 31.5% for loss on ignition, 1.8μm for laser particle size D50, and 97 for whiteness.

[0052] (2) Add the magnesium hydroxide powder raw material into the rotary kiln calciner, control the temperature range from the front part to the rear part in the rotary kiln to be 520°C to 550°C, and control the residence time of the material in the calciner to 1.5h . The magnesia powder after calcining was passed through a vibrating sieve to obtain a magnesia powder product A with 325 meshes passing through. The range of citric acid value for chemical detection of magnesium oxide A reactivity is 125s, and the bulk density is 0.30g / cm 3 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com