Oxidation ditch river water denitrification process and its equipment

An oxidation ditch and process technology, applied in the direction of aerobic and anaerobic process treatment, water pollutants, chemical instruments and methods, etc., can solve the problem of failure to effectively improve the self-purification capacity and load resistance capacity of the river, which is not suitable for popularization and application, treatment The effect of improving impact resistance and pollution holding capacity, improving reaction efficiency and removal efficiency, and efficient denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

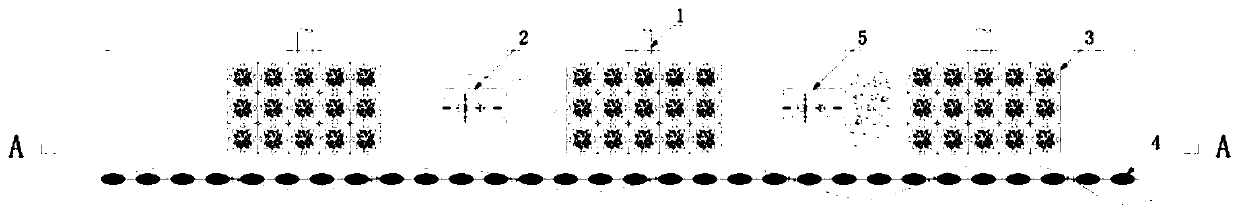

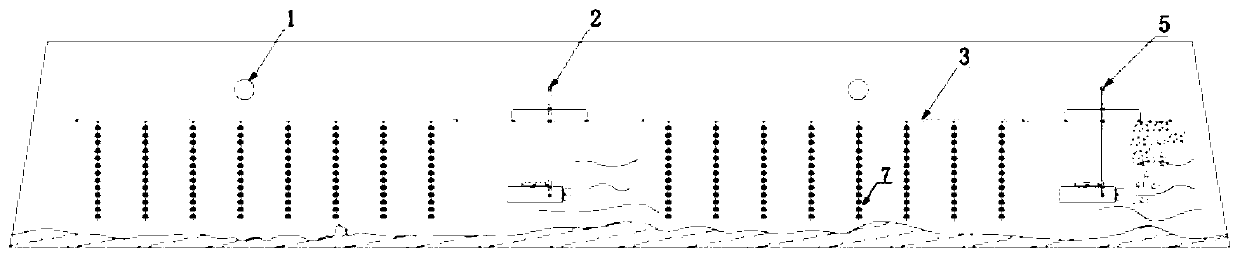

[0047] see Figure 1-2 As shown, it is a structural schematic diagram of a preferred embodiment of the present invention, a kind of oxidation ditch river water denitrification equipment, and the soft open channel sewage interception net 4 arranged in it forms a water passageway with the coast, and there are respectively arranged in the water passageway. Flow mixer 2, push flow aerator 5, ecological floating bed 3, biological filler 7 suspended below the ecological floating bed 3, the restriction of the water passageway makes the pollutants in the water passageway less diluted and the load is larger, plus the ecological floating bed The layout makes the dissolved oxygen consumption in the watershed faster, forming an anoxic / anaerobic section. The mixed flow state is formed in the corridor through the plug-flow mixer, and then the concentration of dissolved oxygen is increased by the plug-flow aerator to form an aerobic section. , repeating the arrangement of equipment in the co...

Embodiment 2

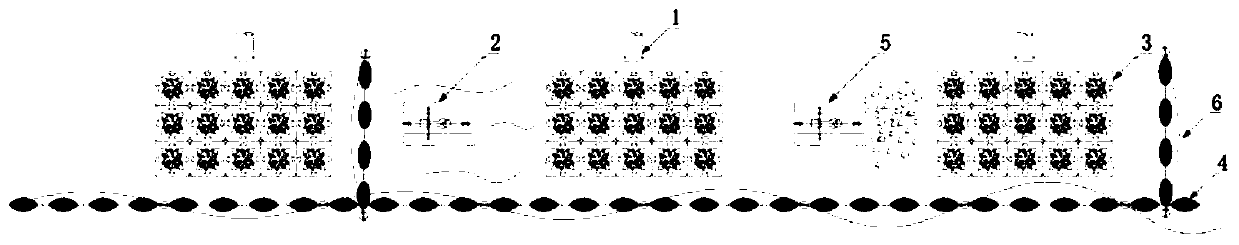

[0050] refer to image 3 As shown, the sequence relationship between the plug flow mixer and 2, the plug flow aerator 5 and the two ecological floating beds 3 is the plug flow mixer and 2, the ecological floating bed, the plug flow aerator 5, and the ecological floating bed, and the horizontal sewage interception is used Net 6 separates it from other equipment to form a separate space. Isolate the corridor into multiple purification areas to maximize the working efficiency of the equipment, avoid affecting the deamination effect due to excessive purification range, and reduce interference factors caused by other spaces.

[0051] Equipment performance parameters:

[0052]

[0053]

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com