Method for preparing submicron order rare-earth zirconate ceramic bulk material

A sub-micron, zirconate technology, applied in the preparation of sub-micron rare earth zirconate ceramic bulk materials, in the field of preparation of rare earth zirconate ceramic bulk materials, can solve the problem of grain growth and inability to form nanometer Ceramic blocks and other problems, to achieve the effect of short heating time, short preparation cycle and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

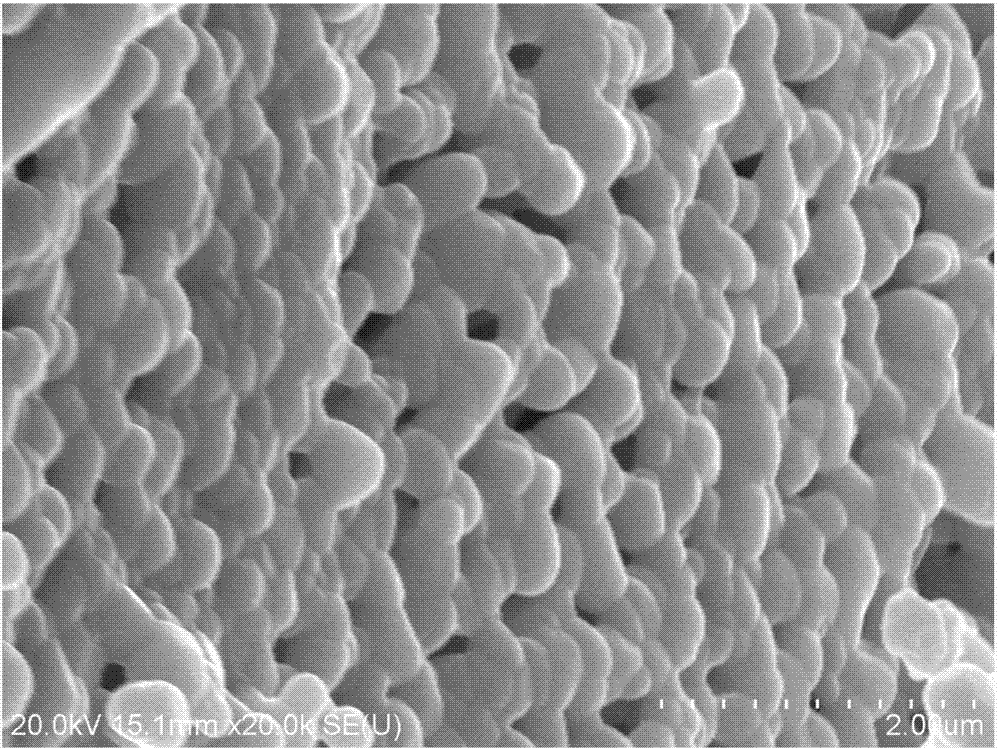

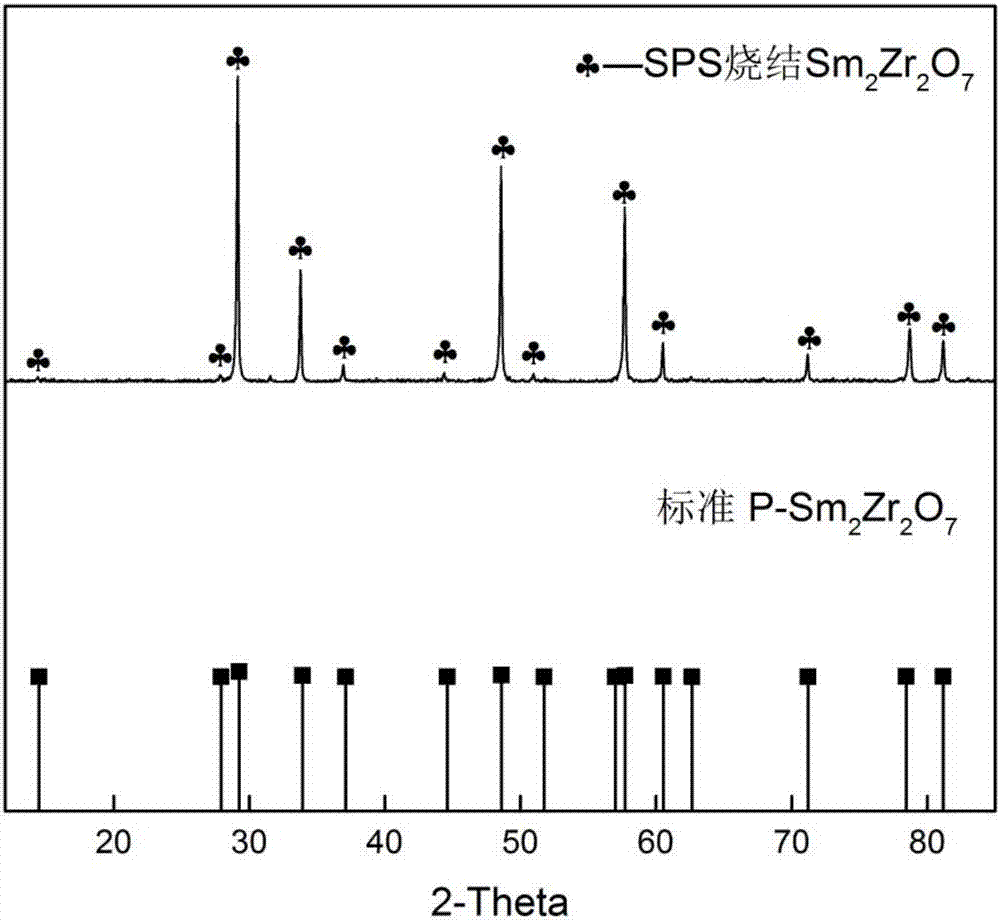

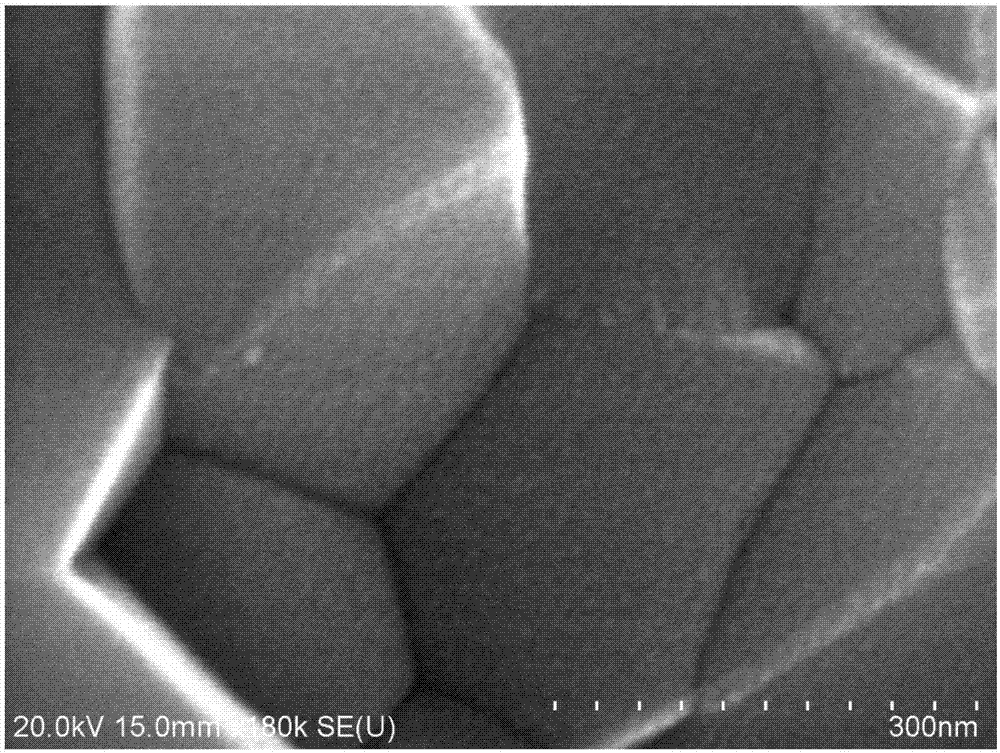

[0029] Submicron Sm 2 Zr 2 o 7 Preparation of ceramic bulk materials:

[0030] (1) 1000g ZrOCl 2 ·8H 2 O dissolved in 950 mL deionized water, 540 g Sm 2 o 3 Dissolve in 3000mL of dilute nitric acid with a mass fraction of 30%, then mix the aqueous solution of zirconium oxychloride with the nitric acid solution of samarium oxide to obtain a mixed solution; then add the mixed solution dropwise to 2000mL of ammonia water with a mass fraction of 17%. Chemical co-precipitation reaction, and the pH of the reaction system is 10 after the reaction is completed, the precipitate produced by the reaction is washed, filtered and dried in an oven to obtain the precursor powder;

[0031] (2) Place the obtained precursor powder in a planetary ball mill with a ball-to-material ratio of 4:1. After ball milling at 300r / min for 20 minutes, the ball-milled powder is passed through a test sieve to obtain a particle size of 20 μm to 80 μm. The powder; then calcined the powder at 1250 °C for ...

Embodiment 2

[0036] Submicron La 2 Zr 2 o 7 Preparation of ceramic bulk materials:

[0037] (1) 1000g ZrOCl 2 ·8H 2 O was dissolved in 950mL deionized water, 505g La 2 o 3 Dissolve in 3200mL of dilute nitric acid with a mass fraction of 30%, then mix the aqueous solution of zirconium oxychloride with the nitric acid solution of lanthanum oxide to obtain a mixed solution; then add the mixed solution dropwise to 2100mL of ammonia water with a mass fraction of 17%. Chemical co-precipitation reaction, and the pH of the reaction system is 10.7 after the reaction is completed, the precipitate produced by the reaction is washed, filtered and dried in an oven to obtain the precursor powder;

[0038] (2) Place the obtained precursor powder in a planetary ball mill with a ball-to-material ratio of 4:1. After ball milling at 400r / min for 10 minutes, the ball-milled powder is passed through a test sieve to obtain a particle size of It is a powder of 20 μm to 80 μm; then the powder is calcined a...

Embodiment 3

[0043] Submicron Gd 2 Zr 2 o 7 Preparation of ceramic bulk materials:

[0044] (1) 1000g ZrOCl 2 ·8H 2 O dissolved in 950 mL deionized water, 580 g Gd 2 o 3 Dissolve in 3400mL of dilute nitric acid with a mass fraction of 30%, then mix the aqueous solution of zirconium oxychloride with the nitric acid solution of gadolinium oxide to obtain a mixed solution; then add the mixed solution dropwise to 2400mL of ammonia water with a mass fraction of 17%. Chemical co-precipitation reaction, and the pH of the reaction system is 10.3 after the reaction is completed, the precipitate produced by the reaction is washed, filtered and dried in an oven to obtain the precursor powder;

[0045] (2) Place the obtained precursor powder in a planetary ball mill with a ball-to-material ratio of 4:1. After ball milling at 300r / min for 20 minutes, the ball-milled powder is passed through a test sieve to obtain a particle size of 20 μm to 80 μm. The powder; then calcined the powder at 1150°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com