Method for preparing shearing strength improving agents for drilling fluid

A cutting agent and drilling fluid technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of ineffective effect, broken chain, failure, etc., to avoid broken chain failure and obvious cutting effect , Improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

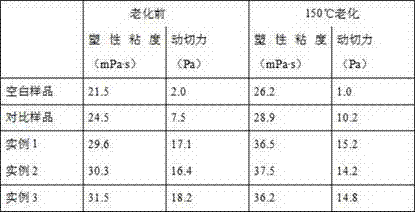

Examples

example 1

[0020] First, add 50g of itaconic acid, 0.4g of azobisisobutyronitrile, 400mL of N,N-dimethylformamide in sequence in the three-necked flask, stir and mix with a glass rod for 15min, then add 30mL of 3-chloropropene, and then put the three-necked flask Transfer to a digital display speed measuring constant temperature magnetic stirrer, and pass nitrogen gas into the three-necked flask at a rate of 5mL / min, under the condition of nitrogen protection, at a temperature of 85°C and a rotation speed of 600r / min, stir and react at a constant temperature for 12h; After the constant temperature stirring reaction is completed and naturally cooled to room temperature, add 10mL of ethylenediamine and 0.5g of N,N'-methylene bisacrylamide to the three-necked flask in sequence, and then move the three-necked flask to a digital speed measuring constant temperature magnetic stirrer , adjust the temperature to 80°C, and the stirring speed to 500r / min. Under constant temperature stirring, add 5 ...

example 2

[0023]First, add 30g of itaconic acid, 0.2g of azobisisobutyronitrile, 300mL of N,N-dimethylformamide into the three-necked flask, stir and mix with a glass rod for 10min, then add 20mL of 3-chloropropene, and then put the three-necked flask Transfer to a digital display speed measuring constant temperature magnetic stirrer, and pass nitrogen gas into the three-necked flask at a rate of 3mL / min, under the condition of nitrogen protection, at a temperature of 80°C and a rotation speed of 400r / min, stir and react at a constant temperature for 8h; After the constant temperature stirring reaction is completed and cooled to room temperature naturally, add 8mL of ethylenediamine and 0.3g of N,N'-methylenebisacrylamide to the three-necked flask successively, and then move the three-necked flask to a digital speed measuring constant temperature magnetic stirrer , adjust the temperature to 75°C, and the stirring speed to 300r / min. Under constant temperature stirring, add 3 mL of sulfuri...

example 3

[0026] First, add 40g itaconic acid, 0.2~0.4g azobisisobutyronitrile, 300~400mL N,N-dimethylformamide in sequence in a three-neck flask, stir and mix with a glass rod for 10~15min, then add 20~30mL 3 -Chloropropene, then transfer the three-necked flask to a digital display speed measuring constant temperature magnetic stirrer, and feed nitrogen gas into the three-necked flask at a rate of 3-5mL / min, under nitrogen protection, at a temperature of 80-85°C, Under the condition of 400~600r / min, stir and react at constant temperature for 8~12h; after the stirring reaction at constant temperature is completed and cooled to room temperature naturally, add 8~10mL ethylenediamine, 0.3~0.5g N,N'- Methylbisacrylamide, and then move the three-necked flask to a digital display speed measuring constant temperature magnetic stirrer, adjust the temperature to 75-80°C, and stir at a speed of 300-500r / min. Add 3 to 5 mL of sulfuric acid with a mass fraction of 98% dropwise into the flask, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com