Halogen-free, flame-retardant and environment-friendly photovoltaic cable as well as preparation method and application thereof

A photovoltaic cable, environmental protection technology, applied in the direction of cable/conductor manufacturing, insulating cables, conductor/cable insulation, etc., can solve the problems of high cost, complex production process, poor weather resistance, etc., achieve excellent weather resistance and mechanical properties, production The effect of simple process and huge market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

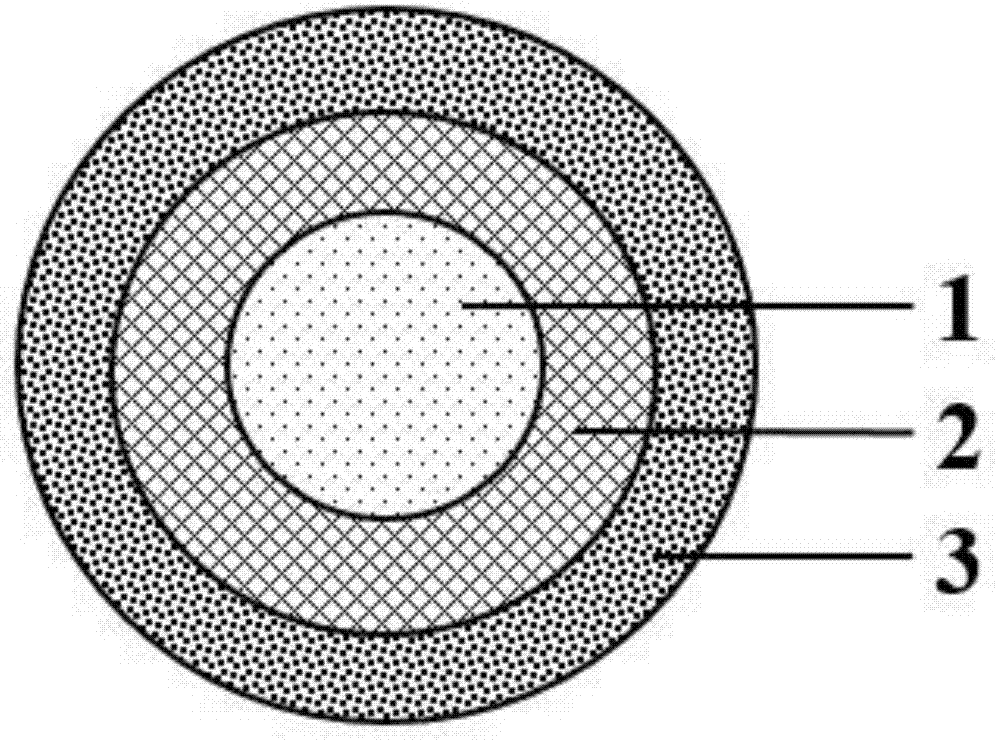

preparation example Construction

[0036] The preparation method of the above-mentioned halogen-free flame-retardant environment-friendly photovoltaic cable comprises the following steps:

[0037] 1) Put all the raw materials into a high-speed mixer, mix them evenly, then add them into a compacting granulator, extrude at 100-140°C, wire drawing, air cooling, and pelletizing to obtain cable materials for insulating layers;

[0038] 2) Put all raw materials into a high-speed mixer, mix and mix them evenly, then add them into a compacting granulator, extrude at 100-140°C, wire drawing, air cooling, and pelletizing to obtain sheath layer cable material;

[0039] 3) Put the conductive core wire, insulation layer cable material and sheath layer cable material into the double-layer co-extruder, co-extrude at 100-150 °C, and then perform radiation cross-linking. The radiation dose is 3-8 Mrad, and no Halogen flame retardant and environmentally friendly photovoltaic cables.

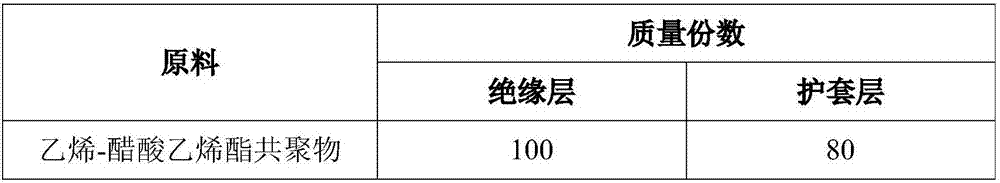

Embodiment 1

[0042] A halogen-free flame-retardant environmentally friendly photovoltaic cable, the raw material composition of its insulating layer and sheath layer is shown in Table 1:

[0043] Table 1 The raw material composition of the insulating layer and the sheath layer of a halogen-free flame-retardant environmentally friendly photovoltaic cable

[0044]

Embodiment 2

[0046] A halogen-free flame-retardant environmentally friendly photovoltaic cable, the raw material composition of its insulating layer and sheath layer is shown in Table 2:

[0047] Table 2 The raw material composition of the insulating layer and the sheath layer of a halogen-free flame-retardant environmentally friendly photovoltaic cable

[0048]

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com