Solid-free, pollution-free, low-injury, high-density well completion fluid and preparation method thereof

A pollution-free, high-density technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low solubility, easy scaling, high price, etc., and achieves simple preparation method, wide applicable temperature, corrosiveness slight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

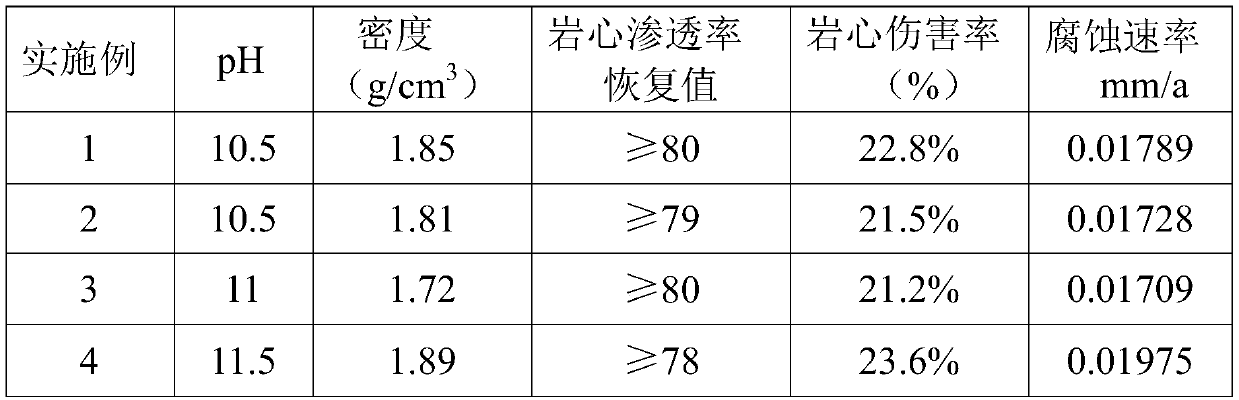

Examples

Embodiment 1

[0018] Add 23 parts of water, 38 parts of potassium monohydrogen phosphate, 8 parts of potassium dihydrogen phosphate, 3 parts of potassium formate, 10 parts of potassium pyrophosphate, and 11 parts of cesium formate into the reaction flask, and stir until completely dissolved. Prepare an inorganic salt aqueous base liquid; add 0.5 parts of xanthan gum to the base liquid, mix well; then add 1.5 parts of fluid loss reducer, mix again, and finally add a pH regulator: 2 parts of potassium hydroxide, Increase the solubility of salt in the liquid system, and prepare a solid-phase, pollution-free, low-damage, high-density completion fluid.

Embodiment 2

[0020] Add 25 parts of water, 29 parts of potassium monohydrogen phosphate, 5 parts of potassium dihydrogen phosphate, 2 parts of potassium formate, 24 parts of potassium pyrophosphate, and 10 parts of cesium formate into the reaction flask, stir until completely dissolved, Prepare an inorganic salt aqueous base liquid; add 0.8 parts of kale gum to the base liquid, mix well; then add 1.2 parts of fluid loss reducer, mix again, and finally add a pH regulator: 3 parts of potassium hydroxide, Increase the solubility of salt in the liquid system, and prepare a solid-phase, pollution-free, low-damage, high-density completion fluid.

Embodiment 3

[0022] Add 29 parts of water, 25 parts of potassium monohydrogen phosphate, 10 parts of potassium dihydrogen phosphate, 4 parts of potassium formate, 20 parts of potassium pyrophosphate, and 6 parts of cesium formate into the reaction flask, stir until completely dissolved, Prepare an inorganic salt aqueous base liquid; add 0.2 parts of guar gum to the base liquid, mix well; then add 1.8 parts of fluid loss reducer, mix again, and finally add pH regulator: 4 parts of potassium hydroxide, increase The solubility of salt in the liquid system is formulated into a solid-phase, pollution-free, low-damage, high-density completion fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com