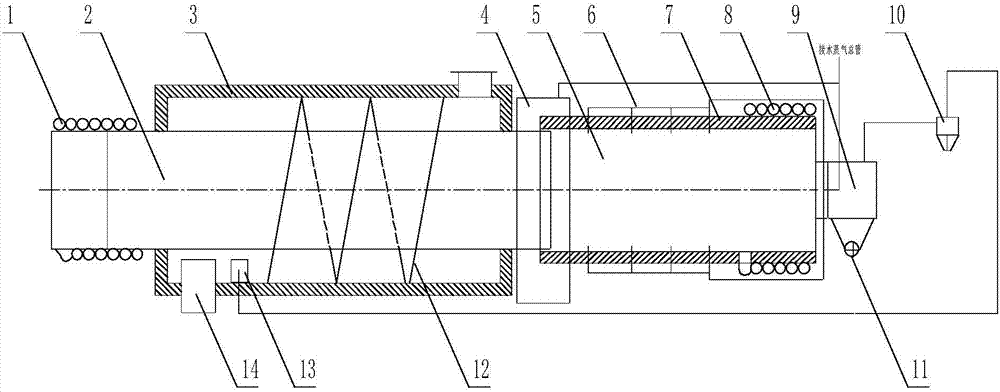

Internal and external integrated biomass rotation pyrolysis gasification device and application

A technology for pyrolysis gasification and biomass, which is applied to the mechanical details of gasification devices, the feeding tools of gasification devices, and the manufacture of combustible gases, etc. It can solve problems such as low carbon quality, reduce exhaust gas temperature, and reduce production costs. , the effect of low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

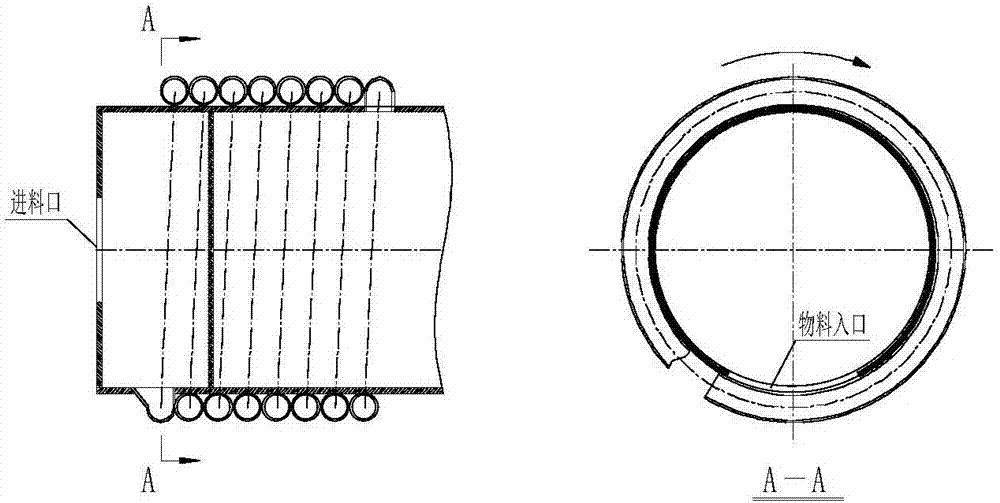

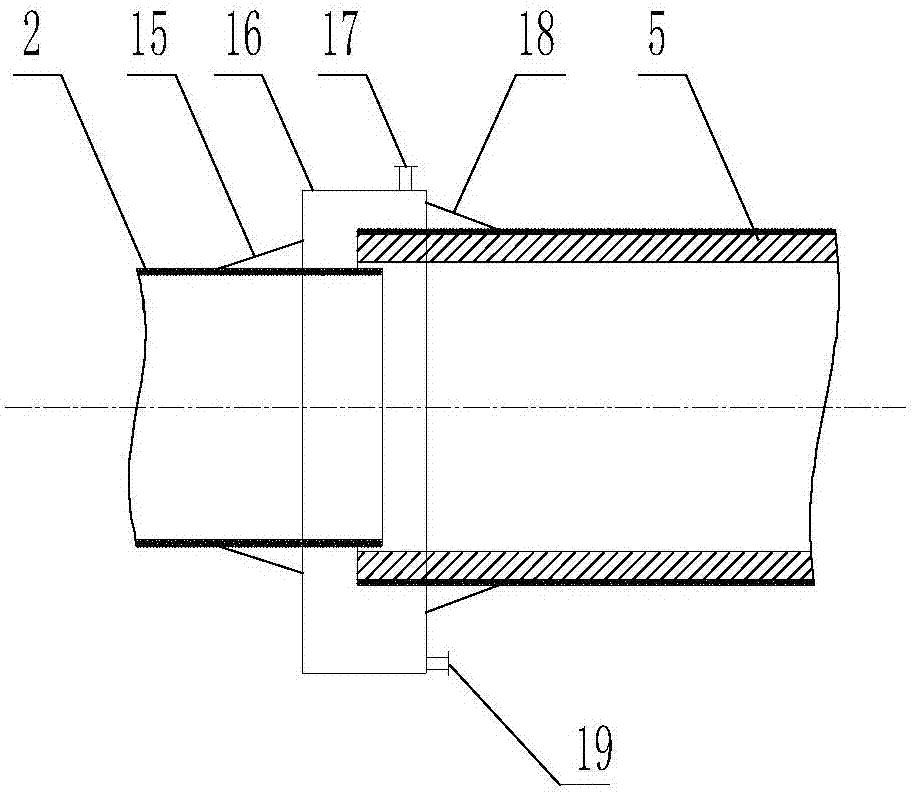

Method used

Image

Examples

Embodiment

[0040] Embodiment: Using wood chips to produce biomass gas and carbon adsorption materials

[0041] The biomass rotary pyrolysis and gasification equipment with internal and external heat integration of the present invention is adopted, the raw material is wood chips, the length is about 20-40mm, and the moisture content is 15-20%. First turn on the pellet burner, raise the temperature of the externally heated rotary furnace to 500-700°C, put the wood chips into the feed bin, the wood chips complete the pyrolysis reaction in the externally heated rotary furnace and enter the internally heated gasification device, and send them into the water The mixture of steam and air, the ratio of water vapor to air is 2:1, and the charcoal gasification and activation reaction occurs in the internal heating gasification device. The reaction temperature is 1100-1200 ℃ to generate gas and activated carbon, and part of the generated gas is sent to the external heat The combustion chamber of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com