A kind of tungsten disulfide/carbon nanofiber composite material and its preparation method and application

A technology of carbon nanofiber and tungsten disulfide, which is applied in the direction of carbon fiber, chemical instruments and methods, fiber treatment, etc., can solve the problems of inhibition performance, easy agglomeration and electrical conductivity, etc., achieve rich pores, solve easy agglomeration, and good electrical conductivity Effect

Inactive Publication Date: 2019-10-01

JIANGSU UNIV

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in practical applications, tungsten disulfide nanosheets often have the problems of easy agglomeration and poor conductivity, which largely inhibit the performance of the material.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

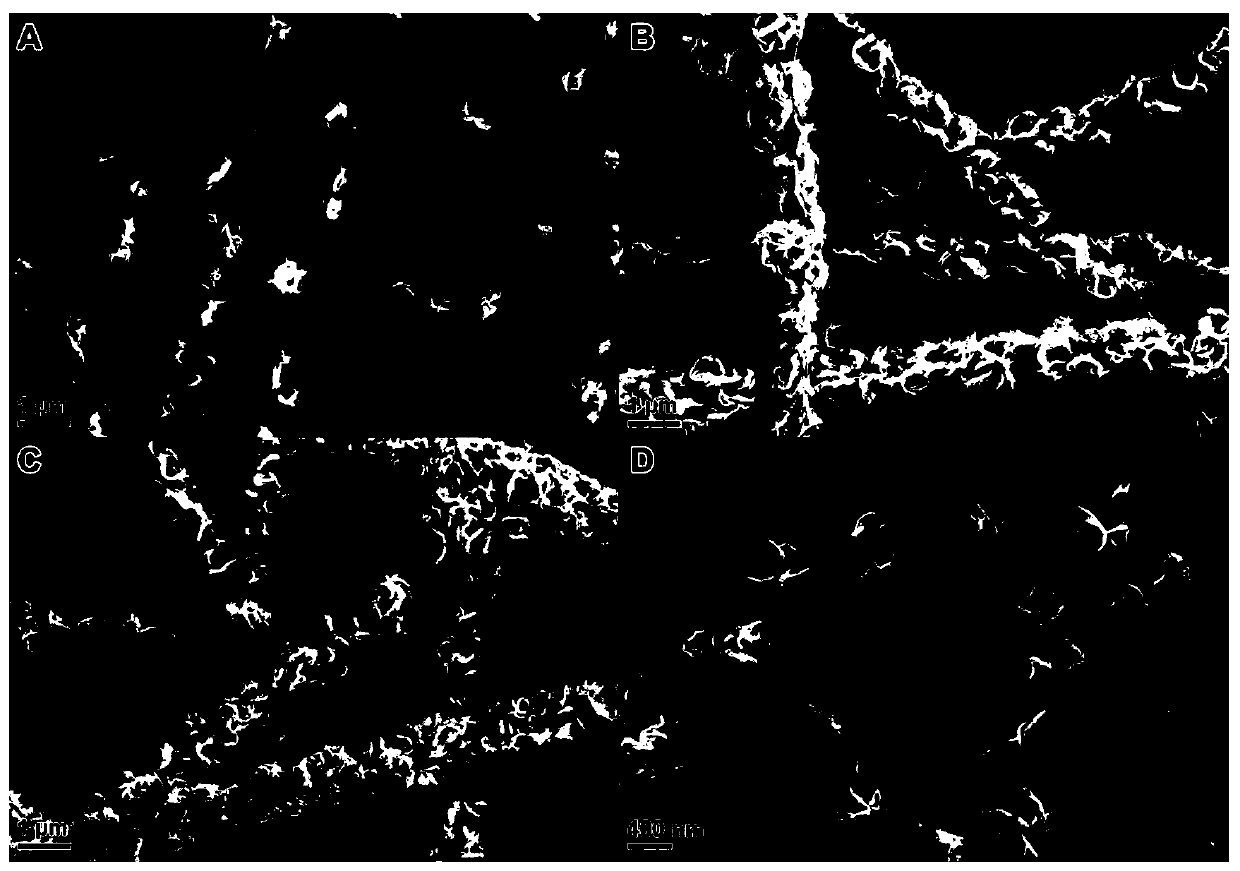

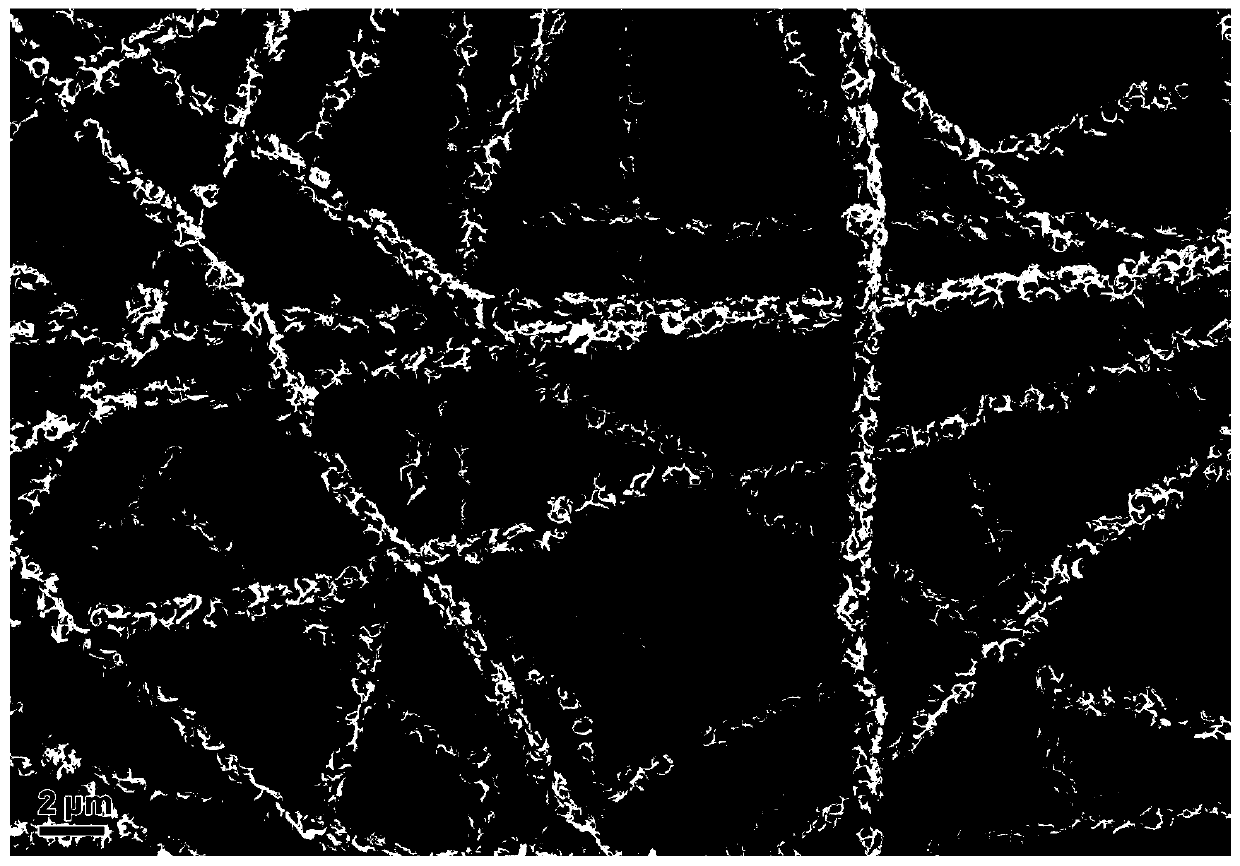

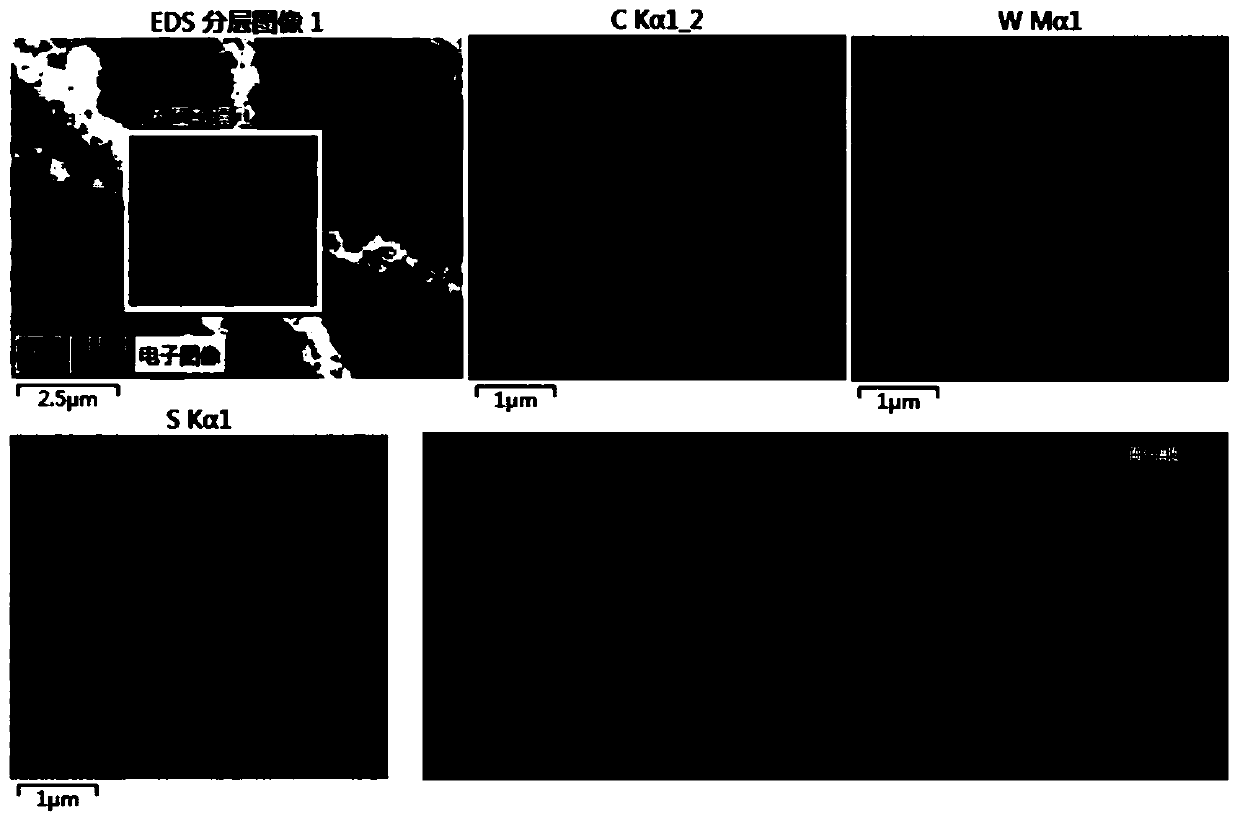

The invention provides a tungsten disulfide / carbon nanofiber composite material and its preparation method and use. The preparation steps are as follows: (1) Under high-speed stirring and oil bath conditions, prepare a polyacrylonitrile spinning solution; (2) Use Preparing polyacrylonitrile nanofibers by electrospinning; (3) Pre-oxidizing the polyacrylonitrile nanofibers in step (2) through programmed temperature control; (4) Pre-oxidizing the polyacrylonitrile nanofibers in step (3) through staged temperature rise The treated polyacrylonitrile nanofibers are carbonized; (5) Add a certain amount of tungsten disulfide precursor compound to the solvent, and obtain a tungsten disulfide precursor solution by ultrasonic; (6) Dip the carbon nanofiber membrane into the tungsten disulfide precursor into a bulk solution, and then placed in a high-pressure reactor to perform a solvothermal reaction at a certain temperature to obtain a tungsten disulfide / carbon nanofiber composite material. The preparation process of the invention is simple, easy to operate, and the polymers and reagents used are environmentally friendly.

Description

technical field The invention belongs to the field of functionalized composite carbon nanometer materials, in particular to a tungsten disulfide / carbon nanofiber composite material and a preparation method thereof. Background technique With the decrease of fossil energy and frequent occurrence of extreme climates, scientists all over the world are committed to developing renewable, low-cost and environmentally friendly energy storage and conversion technologies to meet the needs of mobile electronic devices and new The energy demand brought about by the rapid development of energy vehicles. Among them, supercapacitors, fuel cells, and lithium-ion batteries are considered to be the three most promising electrochemical energy storage and conversion systems. The key to determining the performance of these new energy systems lies in the design and development of high-performance electrode materials and catalyst materials. In order to promote the industrialization of this new e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06M11/53D01F9/22B82Y30/00H01G11/24H01G11/30H01G11/36H01G11/44H01M4/58H01M4/62H01M4/90B01J27/047D06M101/40

CPCH01M4/5815H01M4/625H01M4/9083H01G11/24H01G11/30H01G11/36H01G11/44D01F9/22D06M11/53B82Y30/00B01J27/047D06M2101/40B01J35/33Y02E60/50Y02E60/10

Inventor 黄云鹏袁寿其李华明崔芬赵岩包健

Owner JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com