Dead wind source heat pump shaft anti-freezing system based on heat pipe heat exchange

An air source heat pump and heat pipe heat exchange technology, which is applied in the field of heat pumps, can solve the problems of low energy saving rate, small heat gain, and large energy consumption, and achieve the effects of meeting production process requirements, reducing operating time, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

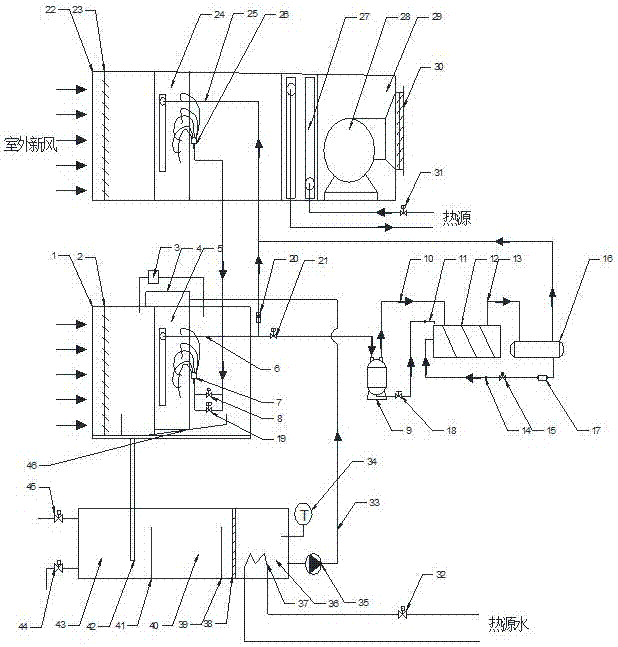

[0027] Example: such as figure 1 As shown, a exhaust air source heat pump wellbore antifreeze system based on heat pipe heat exchange is composed of exhaust air heat extraction device, active and passive air source heat pump unit with heat pipe heat exchanger, exhaust air flushing and defrosting device and heat exchange with heat pipe The mine heating device of the device is composed.

[0028]The exhaust air heating device includes a exhaust air channel 1, which is connected to the exhaust air dry pipe, and an air volume regulating valve 2 is provided at the air inlet of the exhaust air channel 1, and a finned heat exchange pipe is arranged in the exhaust air channel. Heater 5, finned heat pipe heat exchanger 5 is installed on the top of water collection tray 46, the upper end of finned heat pipe heat exchanger 5 is provided with closed spray water tank 4, the inlet of finned heat pipe heat exchanger 5 The air side and the air outlet side are connected to the pressure differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com