Edge sensor system for active reflection plane of radio telescope, and detection method for active reflection plane edge sensor system

A radio telescope and sensor technology, which is applied to instruments, measuring devices, optical devices, etc., can solve the problem of low precision and seeing, heavy workload of batch real-time detection, and inability to real-time detection by radio telescopes and ensure the surface shape accuracy. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

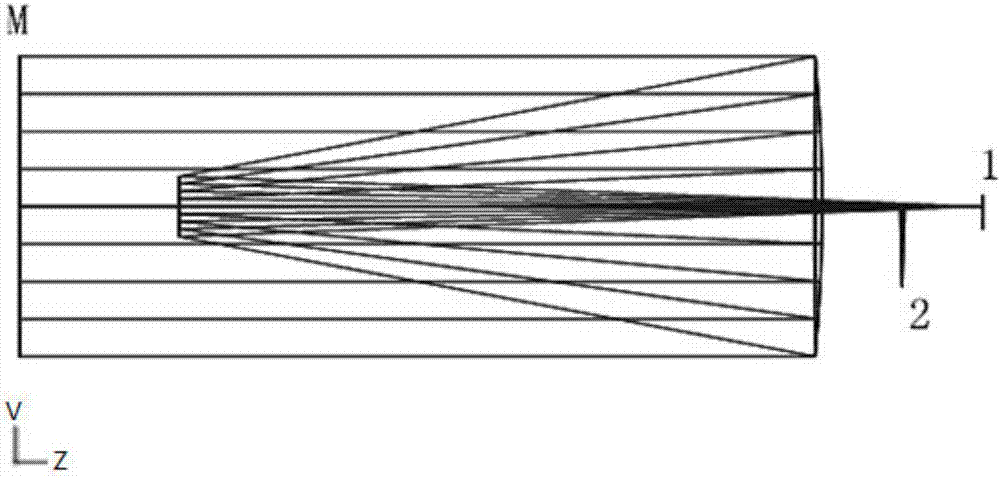

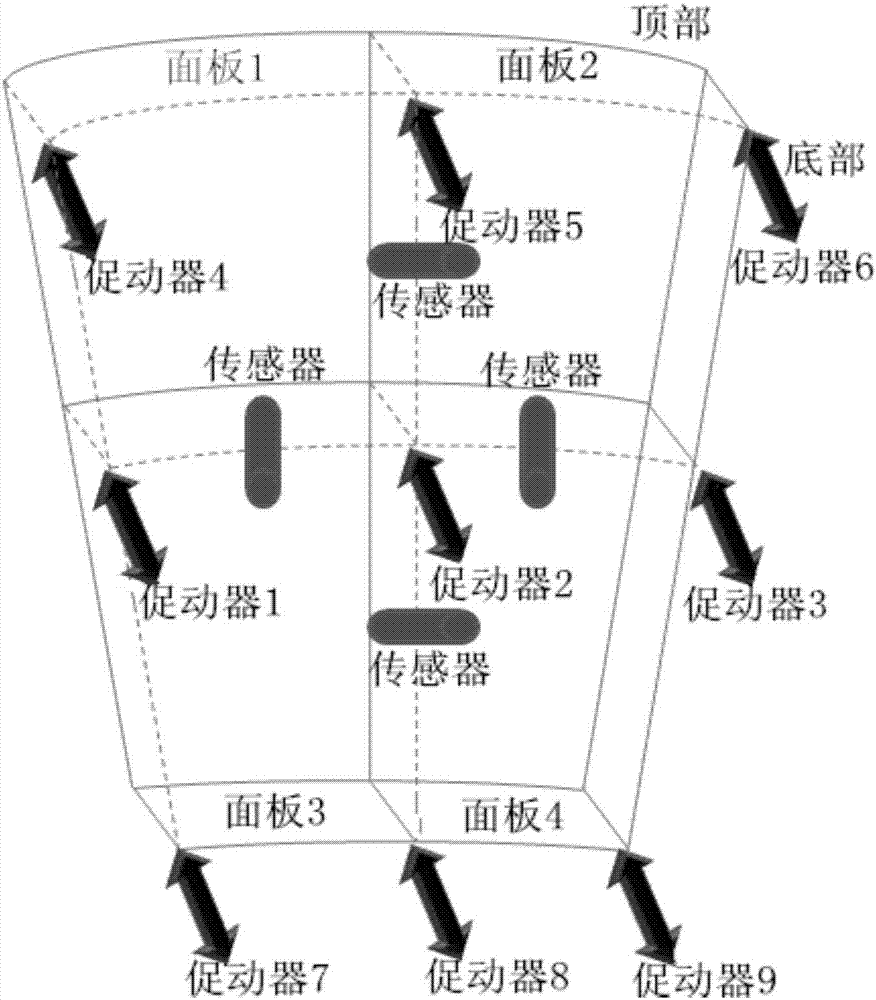

[0046] Embodiment 1, the edge displacement sensor of the reflector of the radio astronomy telescope, carries out figure 1 The optical design of the edge sensor in the center adopts a card system, which increases the focal length by turning the optical path, and the double reflection design eliminates chromatic aberration; the transmitting end (point light source) 2 and the receiving end (target surface) 1 share the optical path and are placed on the edge of a panel. The plane reflector M is placed on the other panel, and the two panels are connected by parallel light to form a complete edge sensor system; the collimated parallel light emitted by the sensor emitter (point light source) is reflected by the plane on the other panel The mirror is reflected back and received by the receiving end (target surface), and the image points are recorded (refer to image 3 The change of the position of the spot profile); through image processing (refer to Pic 4-1 , Figure 4-2 ) to obta...

Embodiment 2

[0047] Embodiment 2 is basically the same as Embodiment 1. In order to switch radio telescopes to different working modes or to achieve large-scale high-precision measurement, the receiver part (target surface) of the edge sensor in the above step (2) uses a high-precision electromagnet Control and switch the field of view / range or the measurement range control mechanism with sensors, realize the switching of two high-precision small measurement ranges, perform measurements in different ranges, and complete the real-time closed-loop calibration of the entire radio telescope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com