Method of rapid determination of hydrogen peroxide content of solution

A hydrogen peroxide, rapid determination technology, applied in the direction of material analysis through observation of the influence of chemical indicators, analysis through chemical reaction of materials, color/spectral characteristic measurement, etc., can solve the cost of toxic determination of reaction reagents, Large errors in measurement results, complex and cumbersome operations, etc., to achieve rapid determination of hydrogen peroxide content, reliable results, and cheap instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of rapid assay method of hydrogen peroxide content in the solution of the present embodiment, it is to carry out according to the following steps:

[0022] Step 1: Make a standard curve:

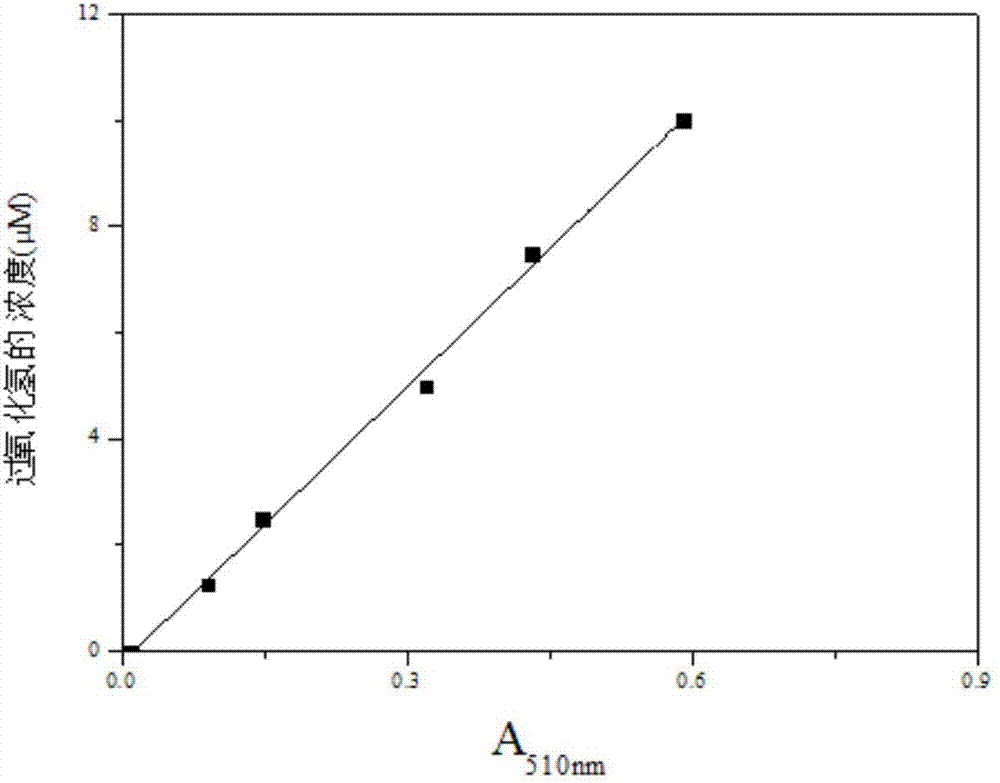

[0023] 1. Add 3mL of ferrous sulfate solution and 1mL of N,N-diethyl-p-phenylenediamine sulfate solution into 5.95mL of distilled water to obtain mixed solution A, measure the absorbance value of mixed solution A at 510nm, and zero ;

[0024] 2. Add 0.05mL of hydrogen peroxide solution standard samples of different concentrations to mixed solution A to form mixed solution B, so that hydrogen peroxide in different mixed solutions B forms a concentration gradient, and the total reaction volume is 10mL;

[0025] 3. After the mixed solution B was oxidized and developed for 0.5 minutes, measure the absorbance value of the mixed solution B at 510 nm after color development, denoted as a;

[0026] 4. Take a as the abscissa and the final concentration of hydrogen peroxide in the mixe...

Embodiment 2

[0041] A kind of rapid assay method of hydrogen peroxide content in the solution of the present embodiment, it is to carry out according to the following steps:

[0042] Step 1: Make a standard curve:

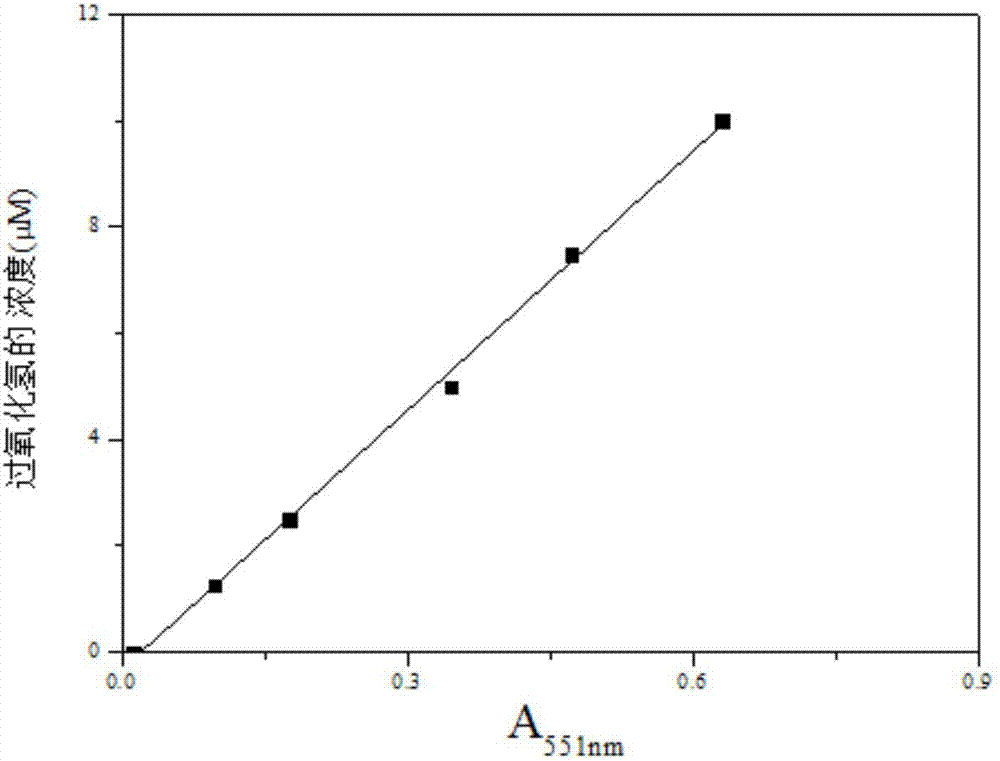

[0043] 1. Add 3mL of ferrous sulfate solution and 1mL of N,N-diethyl-p-phenylenediamine sulfate solution into 6.95mL of distilled water to obtain mixed solution A, measure the absorbance value of mixed solution A at 551nm, and zero ;

[0044] 2. Add 0.05mL of hydrogen peroxide solution standard samples of different concentrations to mixed solution A to form mixed solution B, so that hydrogen peroxide in different mixed solutions B forms a concentration gradient, and the total reaction volume is 10mL;

[0045] 3. After the mixed solution B was oxidized and developed for 0.5 minutes, measure the absorbance value of the mixed solution B at 551 nm after color development, which is recorded as a;

[0046] 4. Take a as the abscissa and the final concentration of hydrogen peroxide i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com