CO emission forecasting system and method for garbage incineration boiler with circulation fluid bed

A domestic waste incineration and circulating fluidized bed technology, which is applied in chemical process analysis/design, special data processing applications, instruments, etc., can solve problems such as inability to achieve sufficient accuracy, strong multilateralism, and complex components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

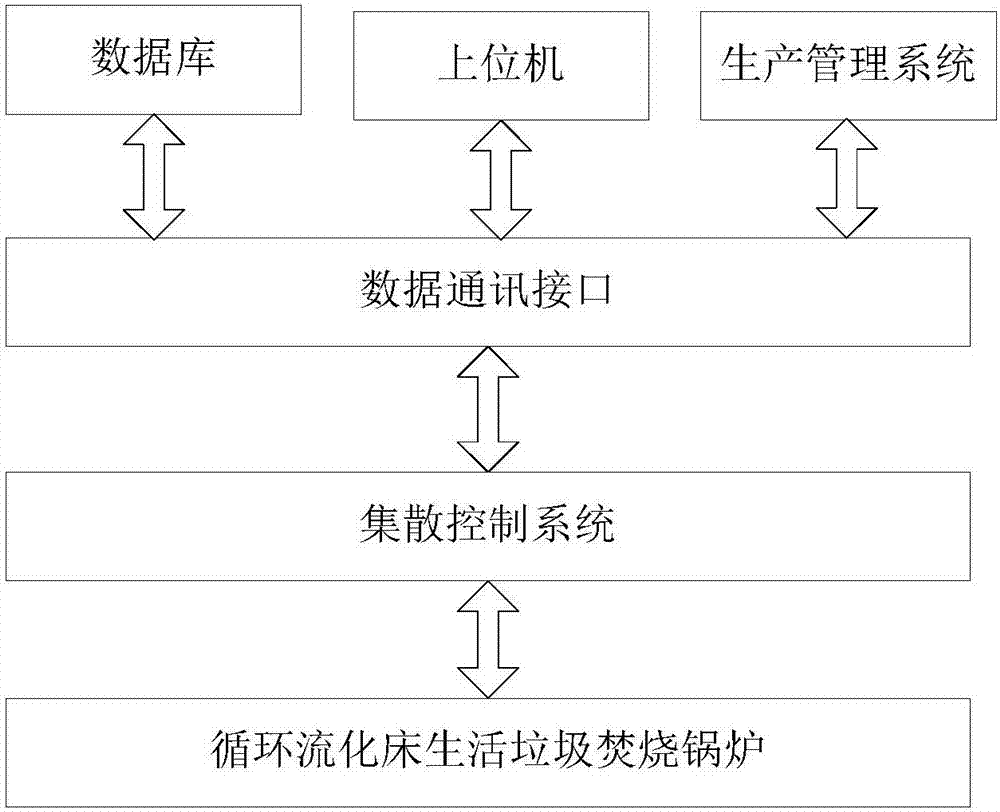

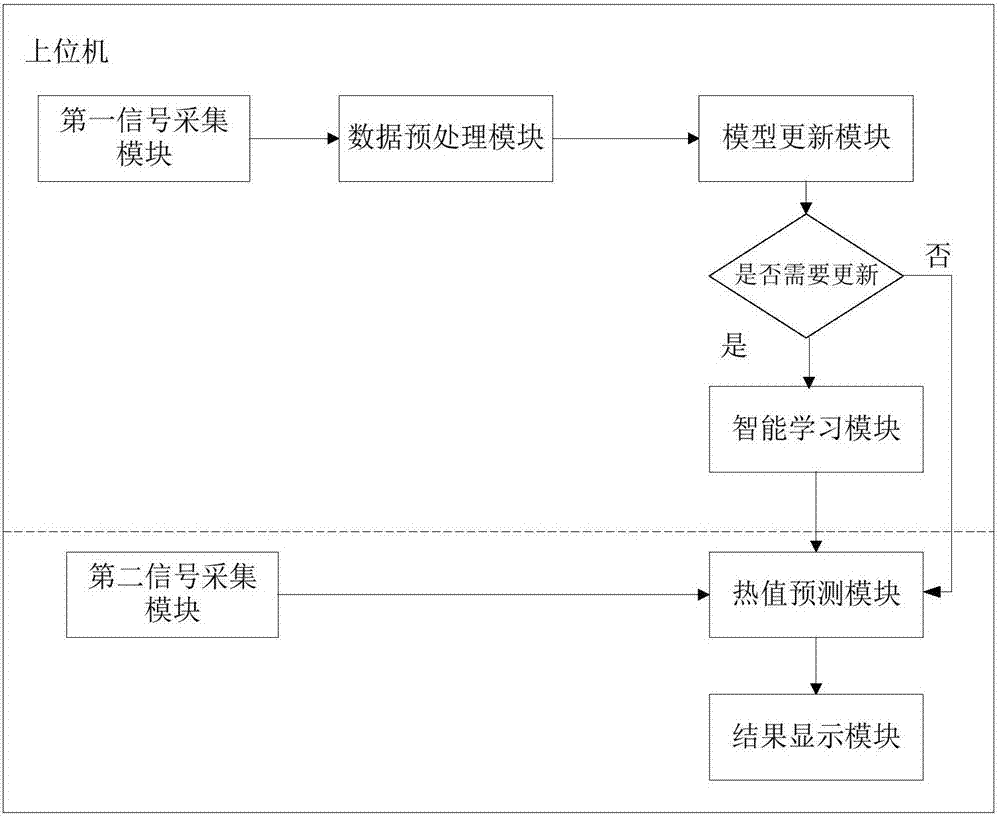

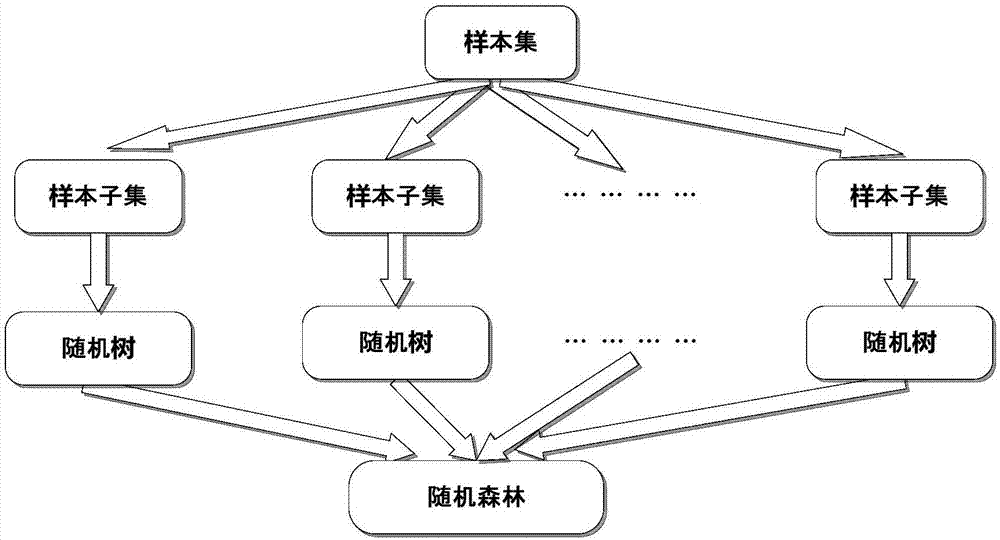

[0087] refer to figure 1 , figure 2 , image 3 , Figure 4 , a CO emission prediction system for a circulating fluidized bed domestic waste incineration boiler provided by the present invention, comprising a circulating fluidized bed domestic waste incineration boiler, a distributed control system for operating control of the boiler, a data communication interface, a database and a host computer. The database reads data from the distributed control system through the data communication interface, and is used for training, learning and testing of the upper computer. The upper computer performs data exchange with the distributed control system through the data communication interface. The upper computer includes online learning, online update, Validation part and online prediction part. Specifically include:

[0088] The first signal acquisition module. This module is used to collect the operating condition parameters and operating variables of the CFB domestic waste incin...

Embodiment 2

[0129] refer to figure 1 , figure 2 , image 3 , Figure 4 , a method for predicting CO emissions from a circulating fluidized bed domestic waste incineration boiler provided by the invention, the method comprises the following steps:

[0130] 1) Analyze the operating mechanism and CO generation mechanism of the circulating fluidized bed domestic waste incineration boiler, and select the waste feeding amount, coal feeding amount, primary air volume, secondary air volume, oxygen content of flue gas, furnace negative pressure, and bed temperature , The temperature in the dilute phase zone of the furnace is used as the input variable of the CO emission prediction model.

[0131] Domestic municipal solid waste is mostly collected in a mixed manner, resulting in complex components of waste entering factories and furnaces. Generally, it mainly includes main components such as kitchen waste, paper, plastic, rubber, fabric, wood, bamboo and inorganic substances, showing low calori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com