Inorganic-organic hybrid gadolinium-based molecular-based low-temperature magnetic refrigeration material and preparation method thereof

A technology of low-temperature magnetic refrigeration and organic hybridization, applied in the fields of organic chemistry, magnetism of organic materials/organic magnetic materials, organic chemistry, etc. Problems such as reporting or use, to achieve the effect of simple method, easy access to raw materials, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, 0.08g gadolinium chloride, 0.05g oxalic acid and 0.2mL hypophosphorous acid are added to 10mL polytetrafluoroethylene as the lining stainless steel reaction kettle and dissolved with 6mL water, then the stainless steel reaction kettle with the reaction solution is sealed, and Crystallize in an oven at 80°C for 3 days. After the reaction is completed, take out the stainless steel reactor and let it cool naturally at room temperature. Remove the crystals generated in the stainless steel reactor and wash them repeatedly with deionized water for 5 times. Dry at room temperature to obtain a colorless blocky crystals.

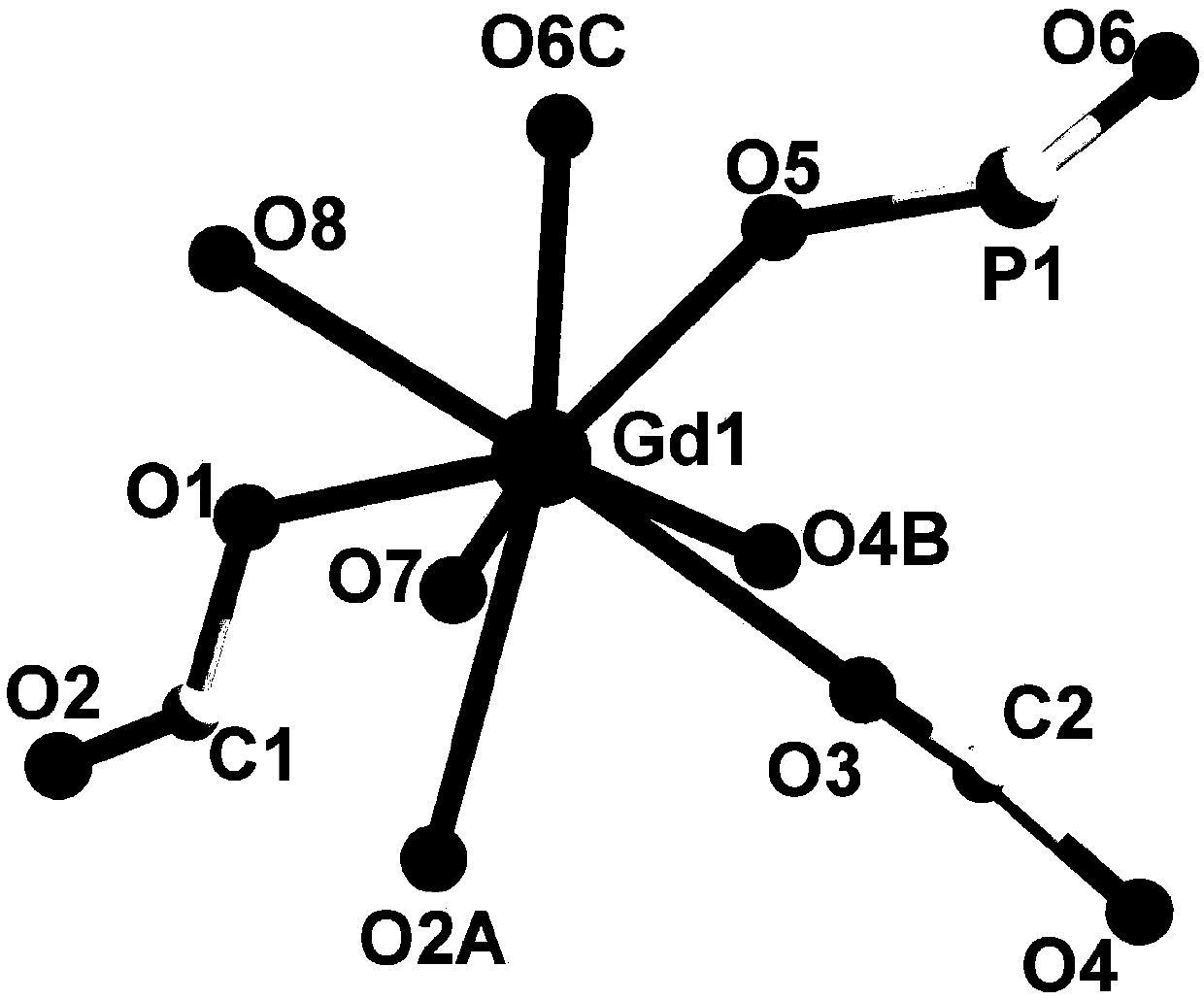

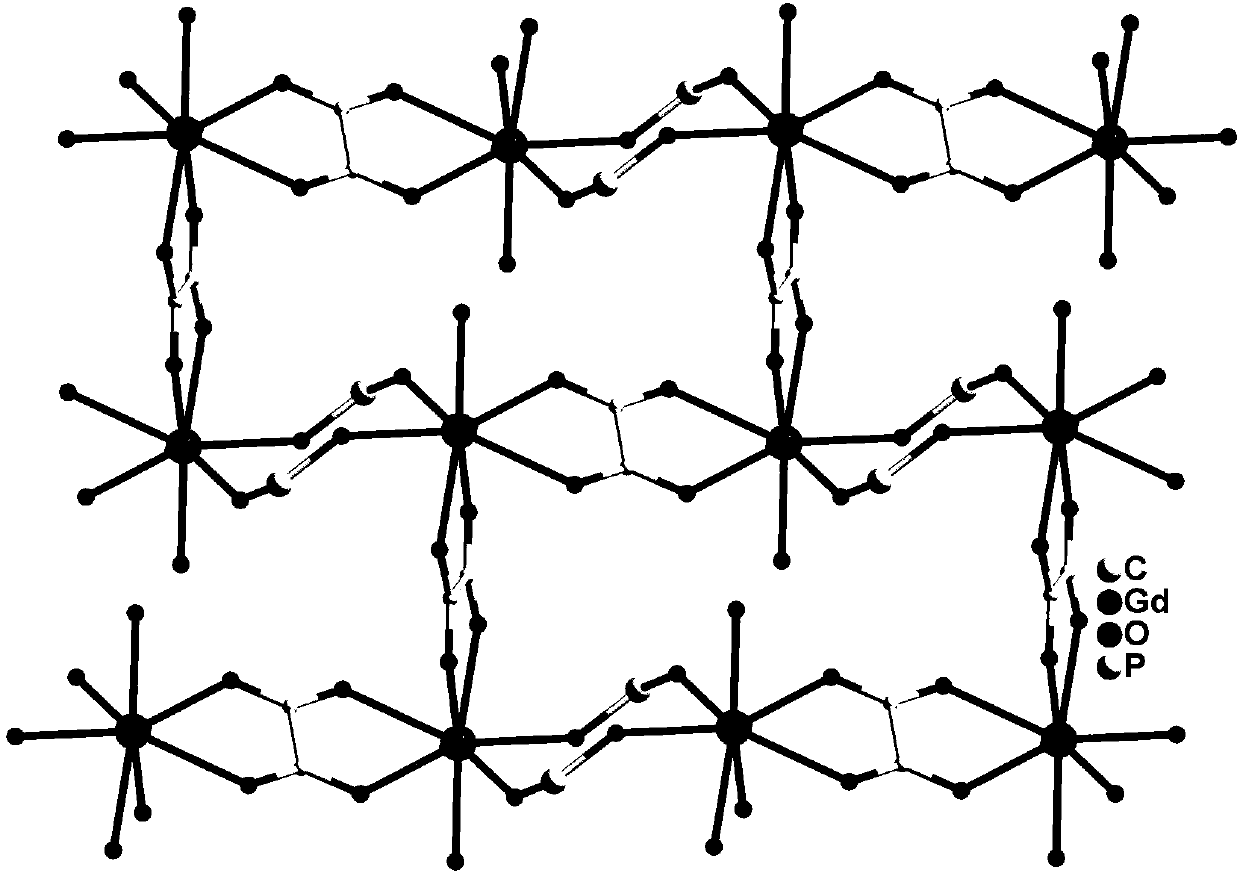

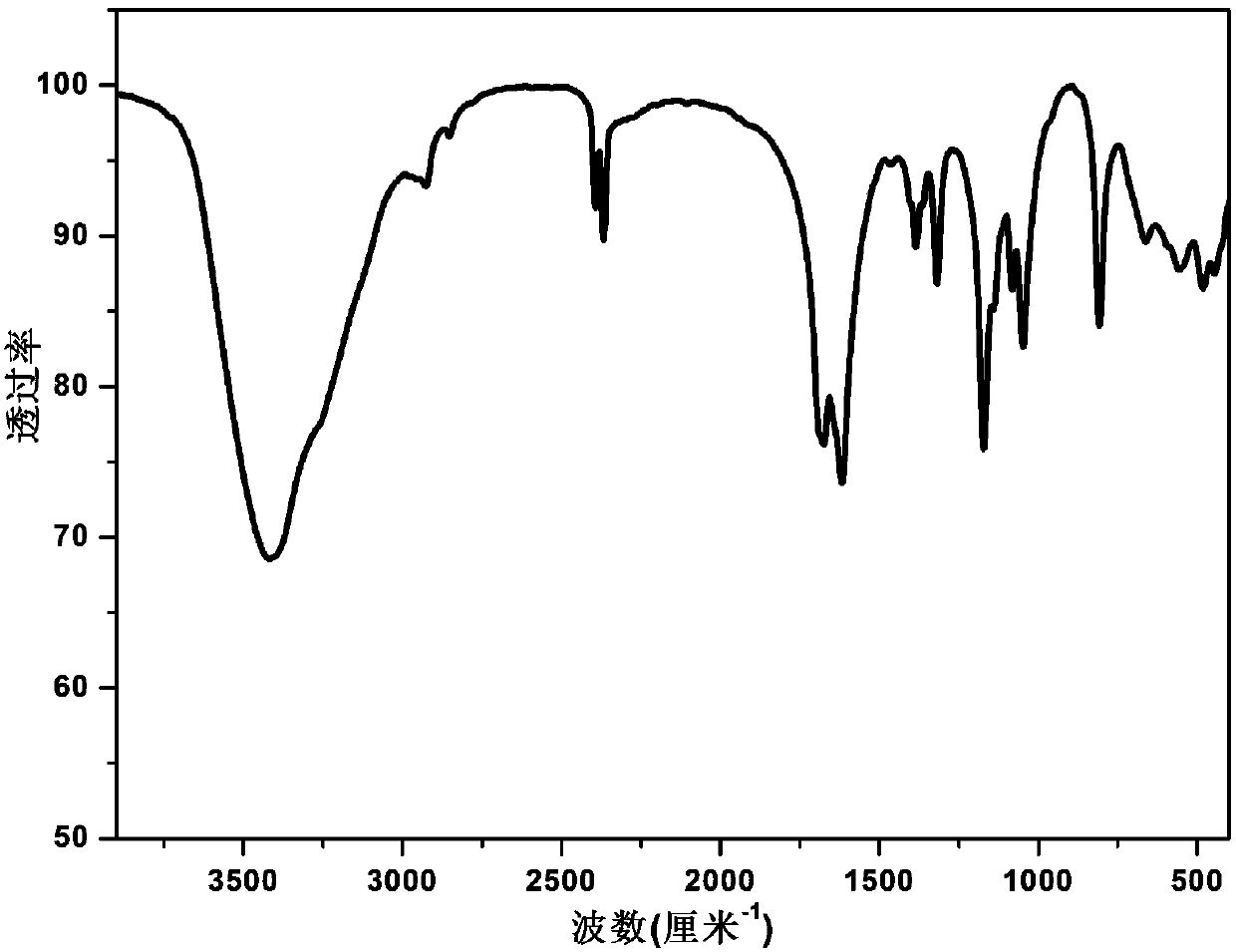

[0029] The single crystal diffraction data analysis of the colorless blocky crystal prepared in this example shows that the obtained complex has a 2D layer structure, wherein the inorganic ligand hypophosphorous acid adopts η 1 :η 1 :μ 2Mode bridging two gadolinium atoms, organic ligand oxalic acid adopts η 1 :η 1 :η 1 :η 1 :μ 2 The ...

Embodiment 2

[0031] In this embodiment, 0.08g gadolinium chloride, 0.05g oxalic acid and 0.3mL hypophosphorous acid are added to 10mL polytetrafluoroethylene as the lining stainless steel reaction kettle and dissolved with 6mL water, then the stainless steel reaction kettle with the reaction solution is sealed, and After crystallization in an oven at 80° C. for 3 days, colorless massive crystals were obtained. After cooling, filtering, washing and drying as in Example 1, the characteristics and results of the target product obtained were the same as those in Example 1.

Embodiment 3

[0033] In this embodiment, 0.08g gadolinium chloride, 0.05g oxalic acid and 0.4mL hypophosphorous acid are added to 10mL polytetrafluoroethylene as the lining stainless steel reaction kettle and dissolved with 6mL water, then the stainless steel reaction kettle with the reaction solution is sealed, and After crystallization in an oven at 80° C. for 3 days, colorless massive crystals were obtained. After cooling, filtering, washing and drying as in Example 1, the characteristics and results of the target product obtained were the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com