Ceramic glaze and preparation method thereof

A production method and a technology for ceramic glaze, applied in the field of ceramic glaze products, can solve the problems affecting the quality of ceramic products, poor surface gloss, uneven texture, etc., achieve less glaze impurities, improve glaze gloss, and improve gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

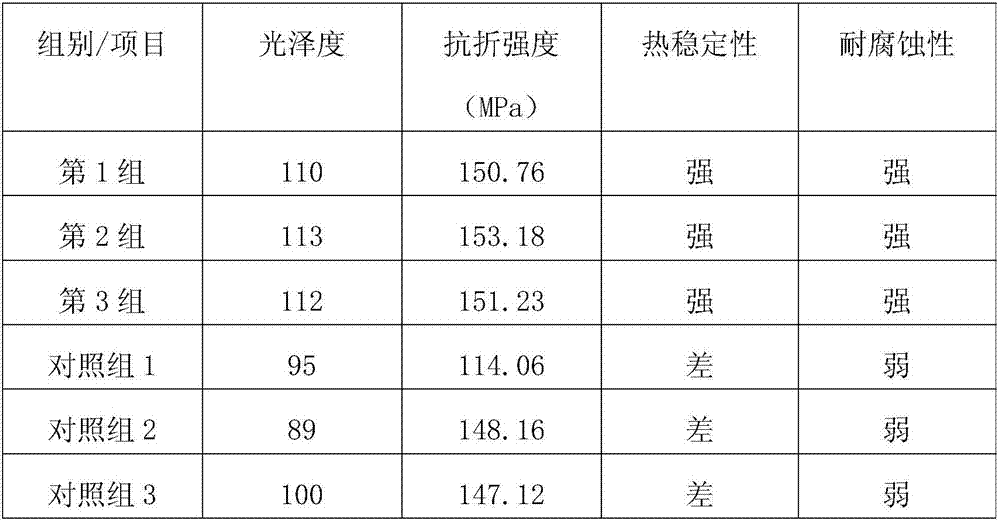

Examples

Embodiment 1

[0024] A kind of ceramic glaze of the present embodiment comprises the following raw materials in parts by weight: 22 parts of green feldspar, 32 parts of anorthite, 19 parts of apatite, 12 parts of allophane, 35 parts of montmorillonite, hexametaphosphoric acid 5 parts of sodium, 1 part of cerium oxide, 3 parts of barium oxide, 4 parts of titanium pentoxide, 8 parts of zinc oxide, 2 parts of tin oxide, 0.7 parts of zinc selenide, 10 parts of aluminum silicate and 3 parts of aluminum oxide; among them, The water content of aluminum silicate is 25%.

[0025] A kind of manufacture method of present embodiment ceramic glaze, comprises the following steps:

[0026] (1) take each raw material by above-mentioned parts by weight;

[0027] (2) Grinding allophane, montmorillonite, sodium hexametaphosphate and aluminum silicate to a fineness of 400-500nm to obtain a mixed powder, adding the mixed powder to 10 times the weight of the mixed powder in water at 55°C After soaking for 1 ho...

Embodiment 2

[0032] A kind of ceramic glaze of the present embodiment comprises the following raw materials in parts by weight: 32 parts of green feldspar, 39 parts of anorthite, 24 parts of apatite, 17 parts of allophane, 43 parts of montmorillonite, hexametaphosphoric acid 9 parts of sodium, 5 parts of cerium oxide, 6 parts of barium oxide, 8 parts of trititanium pentoxide, 11 parts of zinc oxide, 5 parts of tin oxide, 0.9 parts of zinc selenide, 14 parts of aluminum silicate and 7 parts of aluminum oxide; among them, The water content of aluminum silicate is 35%.

[0033] A kind of manufacture method of present embodiment ceramic glaze, comprises the following steps:

[0034] (1) take each raw material by above-mentioned parts by weight;

[0035] (2) Grinding allophane, montmorillonite, sodium hexametaphosphate and aluminum silicate to a fineness of 400-500nm to obtain a mixed powder, adding the mixed powder to water at 65°C that is 18 times the weight of the mixed powder After soakin...

Embodiment 3

[0040] A kind of ceramic glaze of the present embodiment comprises the following raw materials in parts by weight: 28 parts of green feldspar, 35 parts of anorthite, 22 parts of apatite, 16 parts of allophane, 40 parts of montmorillonite, hexametaphosphoric acid 6 parts of sodium, 2 parts of cerium oxide, 4 parts of barium oxide, 5 parts of trititanium pentoxide, 9 parts of zinc oxide, 3 parts of tin oxide, 0.8 parts of zinc selenide, 12 parts of aluminum silicate and 5 parts of aluminum oxide; among them, The water content of aluminum silicate is 25-35%.

[0041] A kind of manufacture method of present embodiment ceramic glaze, comprises the following steps:

[0042] (1) take each raw material by above-mentioned parts by weight;

[0043] (2) Grinding allophane, montmorillonite, sodium hexametaphosphate and aluminum silicate to a fineness of 400-500nm to obtain a mixed powder, adding the mixed powder to 15 times the weight of the mixed powder in water at 60°C After soaking f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com