Epoxy resin composition with antibacterial function and manufacturing method of epoxy resin composition

A technology of epoxy resin and composition, which is applied in the field of polymers and can solve problems such as lack of antibacterial function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

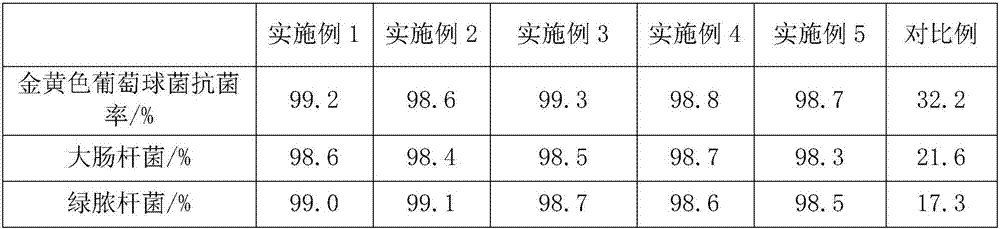

Examples

Embodiment 1

[0026] The epoxy resin composition with antibacterial function is composed of the following raw materials in parts by weight: 100 parts of a mixture of epoxy resin E51 and epoxy resin E44, 15 parts of 4,4'-diaminodiphenylmethane, 1.1 parts of DMP-30 25 parts of quartz powder, 12 parts of a mixture of ammonium polyphosphate and melamine, 1.2 parts of palm wax, 1.1 parts of antioxidant DNP, 5 parts of dibutyl phthalate, and 4.5 parts of antibacterial agent.

[0027] Its manufacturing method is:

[0028] (1) Add butyl titanate to absolute ethanol, stir magnetically for half an hour to obtain solution A, add molybdenum nitrate and ferric nitrate to the mixture of absolute ethanol and deionized water, stir magnetically until uniformly mixed to obtain solution B, Add solution A to solution B dropwise, stir for 2 hours to obtain a sol, age the sol at room temperature for 20 hours to obtain a wet gel, put it in an oven at 70°C for 9 hours to obtain a dry gel, and transfer it to a calc...

Embodiment 2

[0033] The epoxy resin composition with antibacterial function is composed of the following raw materials in parts by weight: 100 parts of a mixture of epoxy resin E51 and epoxy resin E44, 13 parts of 4,4'-diaminodiphenylmethane, 1.3 parts of DMP-30 23 parts of quartz powder, 14 parts of a mixture of ammonium polyphosphate and melamine, 1 part of palm wax, 1.3 parts of antioxidant DNP, 7 parts of dibutyl phthalate, and 4.8 parts of antibacterial agent.

[0034] The manufacture method of this epoxy resin composition is with embodiment 1.

Embodiment 3

[0036] The epoxy resin composition with antibacterial function is composed of the following raw materials in parts by weight: 100 parts of a mixture of epoxy resin E51 and epoxy resin E44, 11 parts of 4,4'-diaminodiphenylmethane, 1.5 parts of DMP-30 21 parts of quartz powder, 16 parts of a mixture of ammonium polyphosphate and melamine, 1.8 parts of palm wax, 0.9 parts of antioxidant DNP, 9 parts of dibutyl phthalate, and 4 parts of antibacterial agent.

[0037] The manufacture method of this epoxy resin composition is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com