Compound bacteria adapting to uranium ore leaching system and application thereof

A technology of compound flora and uranium ore, applied in the directions of bacteria, process efficiency improvement, microorganism-based methods, etc., can solve problems such as difficult leaching, and achieve the effect of environmental friendliness and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

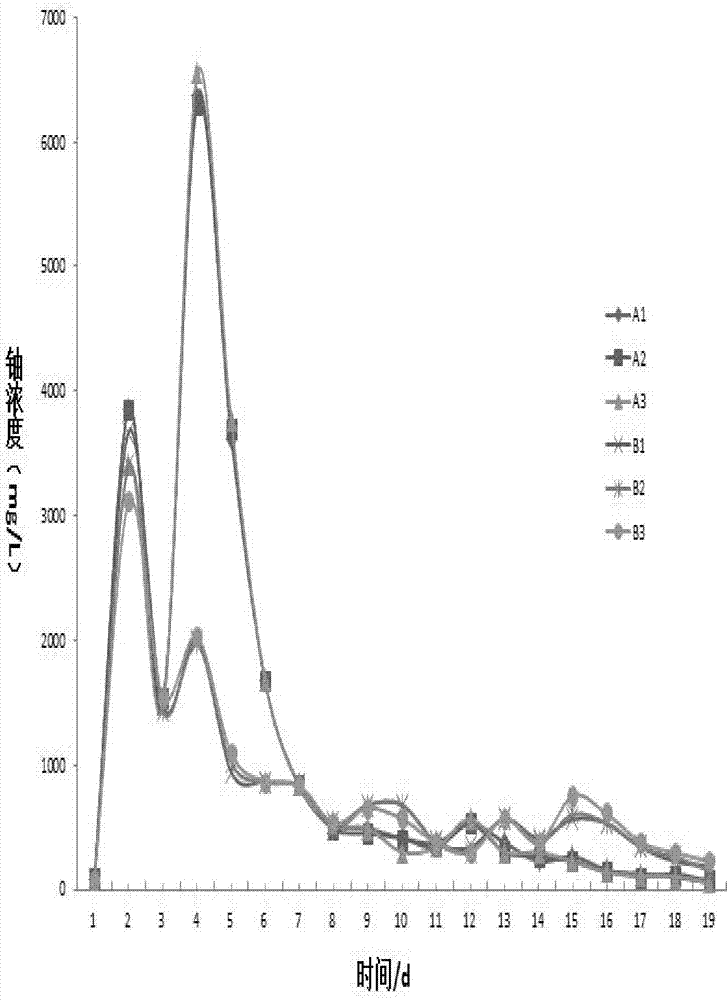

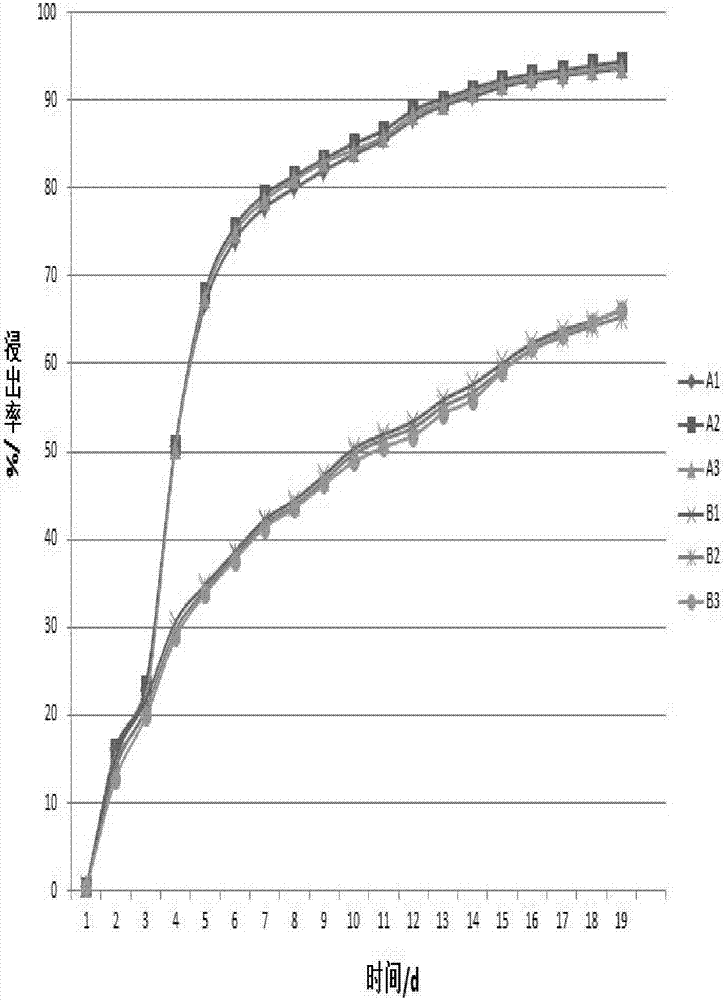

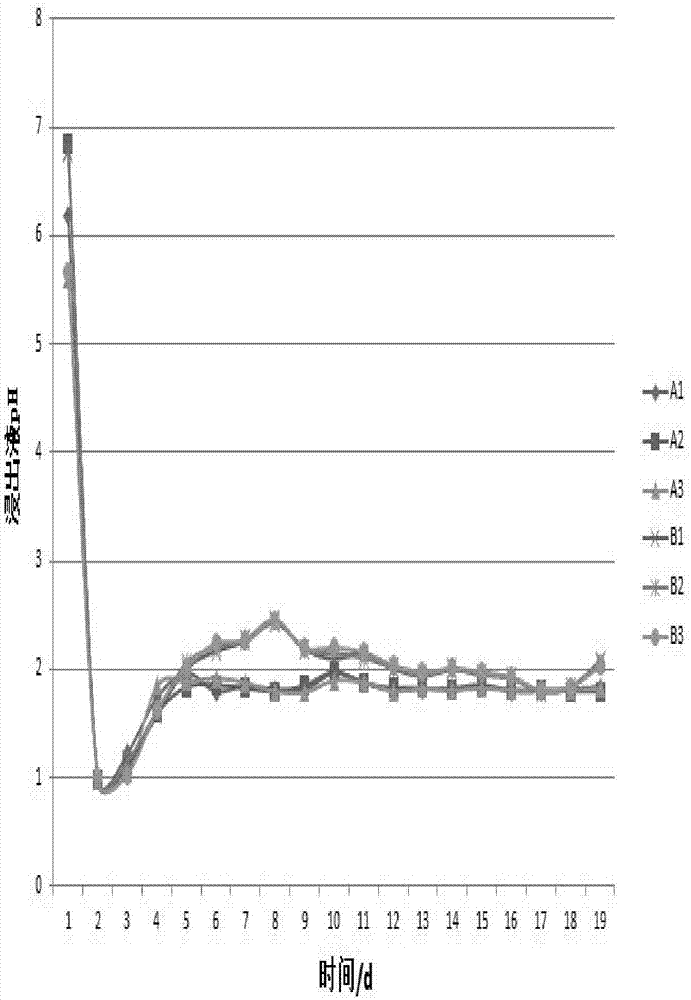

[0041] Example 1 Comparison of the leaching effects of chemical leaching and microbial complex flora leaching on titanium uranium ore

[0042] In this example, the leaching with sulfuric acid plus potassium chlorate at room temperature is compared with the leaching of microbial metallurgical flora AM12, and the leaching law of titanium uranium ore is discussed.

[0043] (1) Experimental flora: microbial metallurgical flora 05B-10: Leptospirrilium sp., Athidithiobacillus thiooxidans, Athidithiobacillus ferrooxidans, Acidiphilium sp. and Sulfobacillus sp. The inoculation initial concentrations were 60.0%, 30.0%, 5.0%, 1.0% and 4.0% respectively Volume ratio.

[0044] (2) Ore source: a uranium ore titanium uranium ore with a grade of 6.407%.

[0045] (3) Test plan: In this experiment, two groups were designed for comparison, and three groups were paralleled. During the test, shaking table vibration (160r / min) was used. 250ml Erlenmeyer flask, 20g of ore passing through 200 mesh...

Embodiment 2

[0051] Example 2 Electron probe analysis of chemical leaching and microbial complex flora leaching on titanium uranium ore

[0052] In this example, chemical leaching and microbial leaching are analyzed and compared on the raw ore and tailings electronic probe, and the treatment effects of the two methods on titanium-uranium ore are discussed.

[0053] 1) Raw ore:

[0054] Electron probes were carried out on uranium minerals in 4 typical uranium ore thin-section samples from a deposit, and 21 probe points were drilled in total. The mineral composition of the uranium ore, especially the type, particle size, occurrence state and output of the uranium ore were basically ascertained through the results of electronic probe and NEP analysis. After analysis and testing, the uranium minerals in the samples are mainly pitchblende, titanite, uranite and a small amount of uranite. The particle size of uranium minerals varies, most of which are between 10 and 100 μm, and are produced in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap