Bra prepared from taxus chinensis viscose fibers

A technology of viscose fiber and yew, applied in the field of textiles, can solve the problems of health impact, high price, unsuitable for ordinary people's daily wear and use, etc., and achieve the effect of smooth hand feeling, good elasticity and good gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

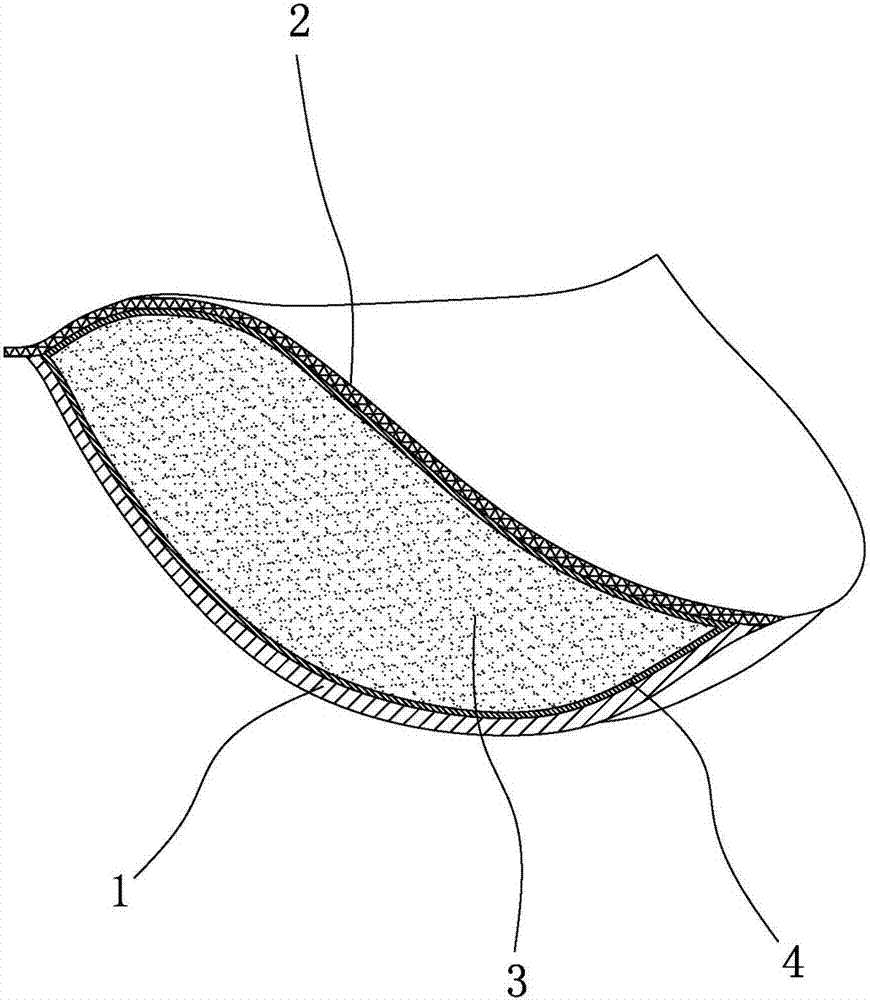

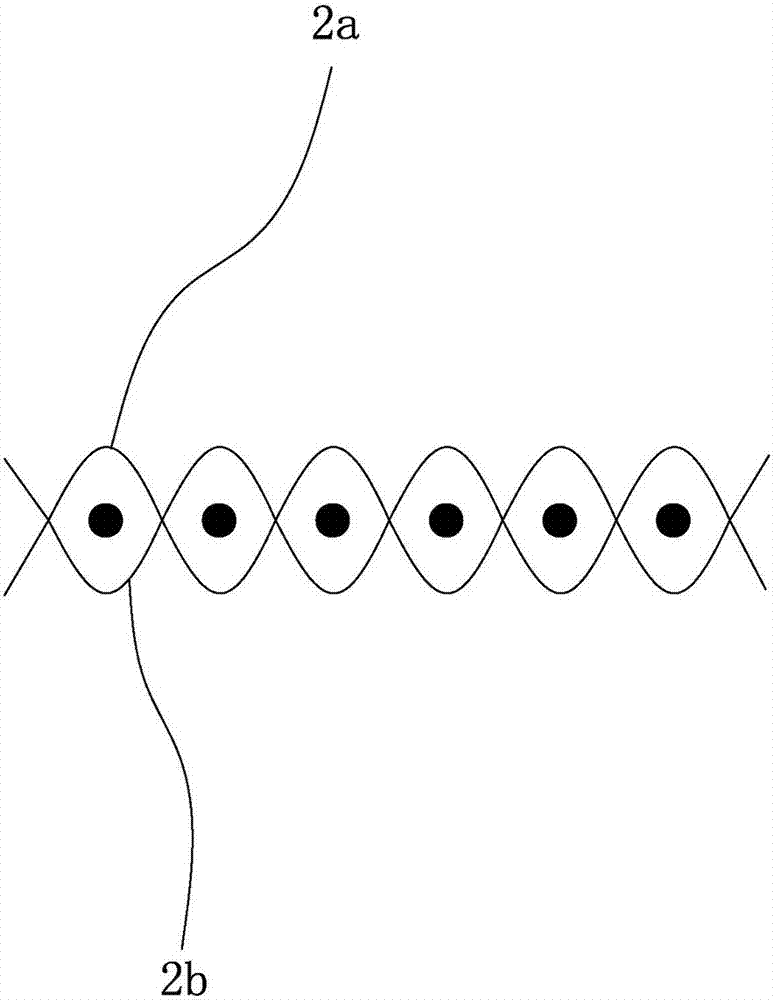

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0023] This yew viscose fiber is made by the following steps:

[0024] 1) Material selection: select mature yew branches and leaves as raw materials;

[0025] 2) Cleaning: Rinse the selected yew branches and leaves under warm water at 30° to 65° for 10 to 15 minutes;

[0026] 3) Pound the cleaned yew branches and leaves in a mortar to get out the slurry, then add dilute lye, remove most of the lignin and hemicellulose, and obtain the yew decomposition product;

[0027] 4) The yew decomposed product obtained in 3) is divided and thinned by a mechanical processing and dividing machine. The temperature during dividing is 10° to 20°, and the dividing time is 20 to 30 minutes;

[0028] 5) Add dilute lye to the decomposed yew ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com