A packaging box and its modified tear-resistant and water-resistant light-coated white-faced kraft cardboard

A kraft paper and packaging box technology, which is applied in the field of white-faced kraft paper, can solve the problems of insufficient waterproofness and inability to protect items well, and achieves good oil-proof effect, good chemical resistance stability and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

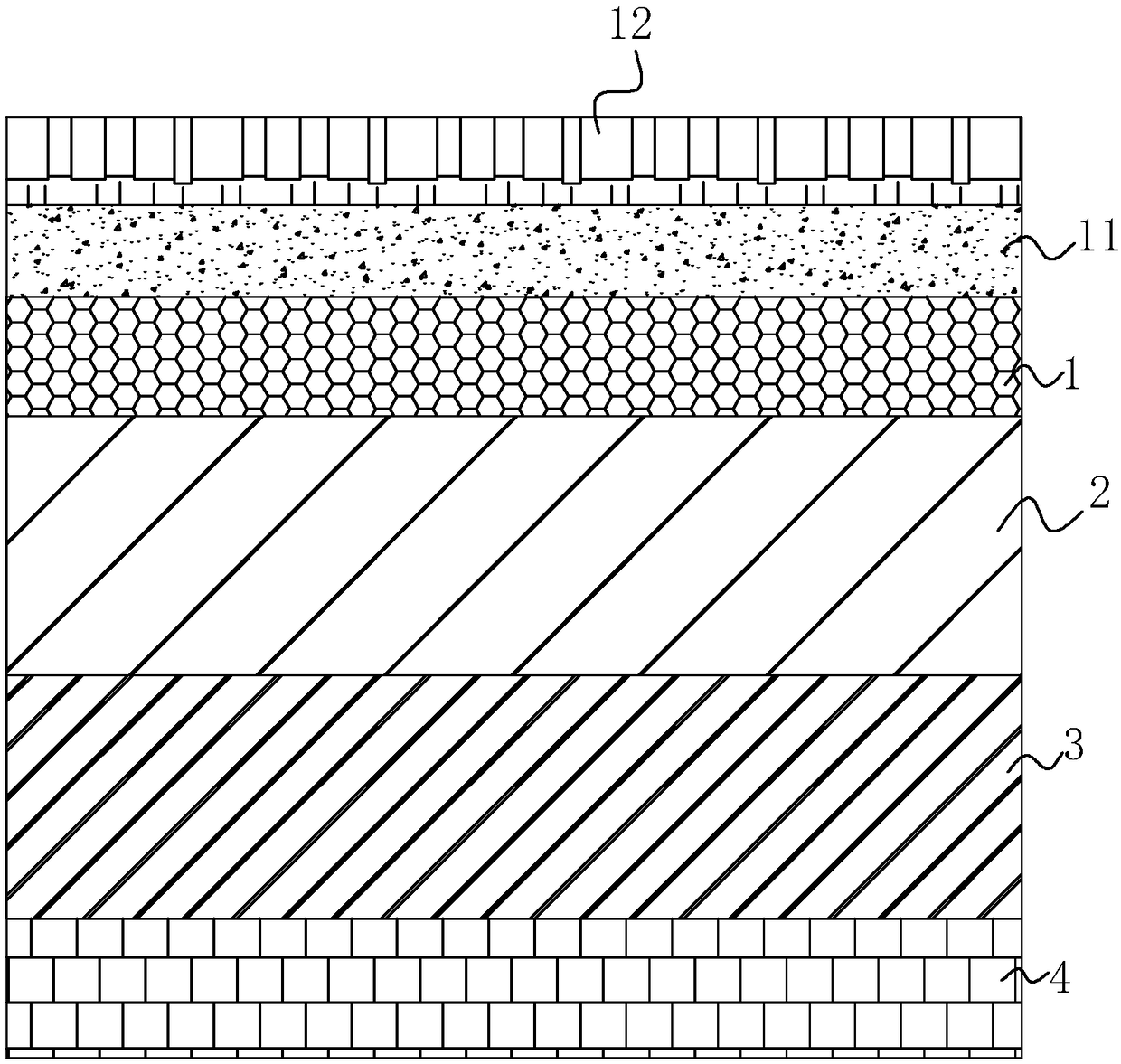

[0044] Modified tear-resistant and water-resistant light-coated white kraft cardboard, such as figure 1 As shown, the amount of coating exposed to the outside including packaging is 10~15g / m 2 The coating layer 11 of the coating layer 11, the surface layer 1 of the coating layer 11, the core layer 2 and the bottom layer 3 sandwiched in the center; the side of the bottom layer 3 away from the core layer 2 also includes a coating amount of 11g / m 2 Waterproof layer 4, the weight of the modified tear-resistant and water-resistant light-coated white-faced kraft cardboard is 230 g / m 2 ; In other embodiments, the quantitative amount of the modified tear-resistant, water-resistant, light-coated white-faced kraft cardboard can be modulated to 210-450g / m as required 2 And correspondingly adjust the coating amount of the waterproof layer 4 to 10-20g / m 2 . The ratio of the two can be controlled so that the ratio of the weight of the light-coated white-faced kraft cardboard to the coati...

Embodiment 2

[0054] Modified tear-resistant and water-resistant light-coated white-faced kraft cardboard, the difference between embodiment two and embodiment one is that the waterproof layer 4 is made of nano-titanium dioxide surface-modified tridecafluorooctyltriethoxysilane; soak the nano-titanium dioxide In an ethanol solvent, tridecafluorooctyltriethoxysilane is added to obtain nano-titanium dioxide with strong hydrophobicity and surface modification of tridecafluorooctyltriethoxysilane;

[0055] Tridecafluorooctyltriethoxysilane is a kind of bifunctional compound, which contains silaneoxyl functional group and releases low molecular weight alcohol after hydrolysis. The resulting active silanol can interact with hydroxyl groups in many inorganic and organic substrates. , carboxyl and oxygen-containing groups produce chemical bonds, making it easier to modify the substrate; its inert and low surface energy groups can make the treated nano-titanium dioxide have extremely low surface ener...

Embodiment 3

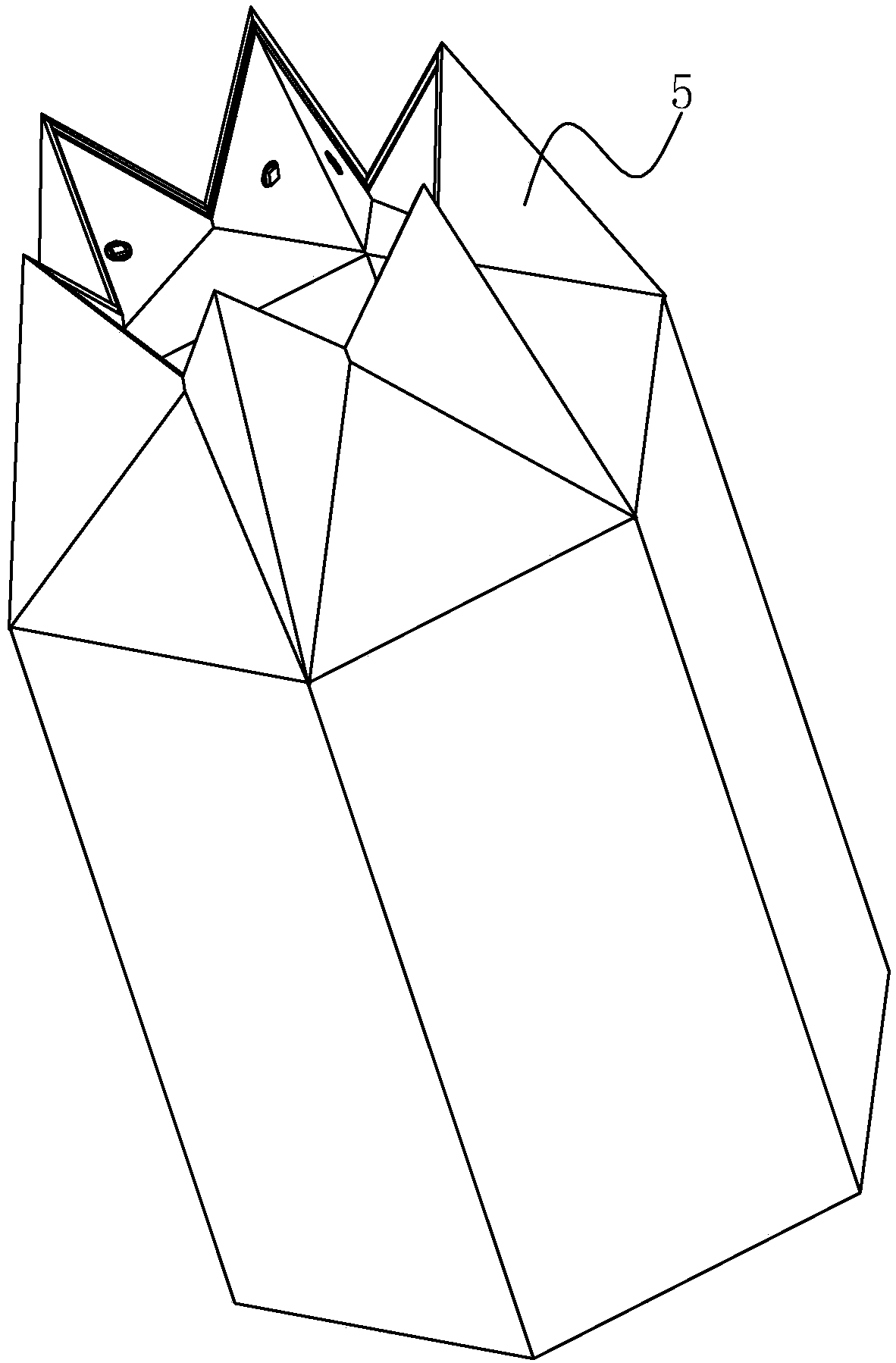

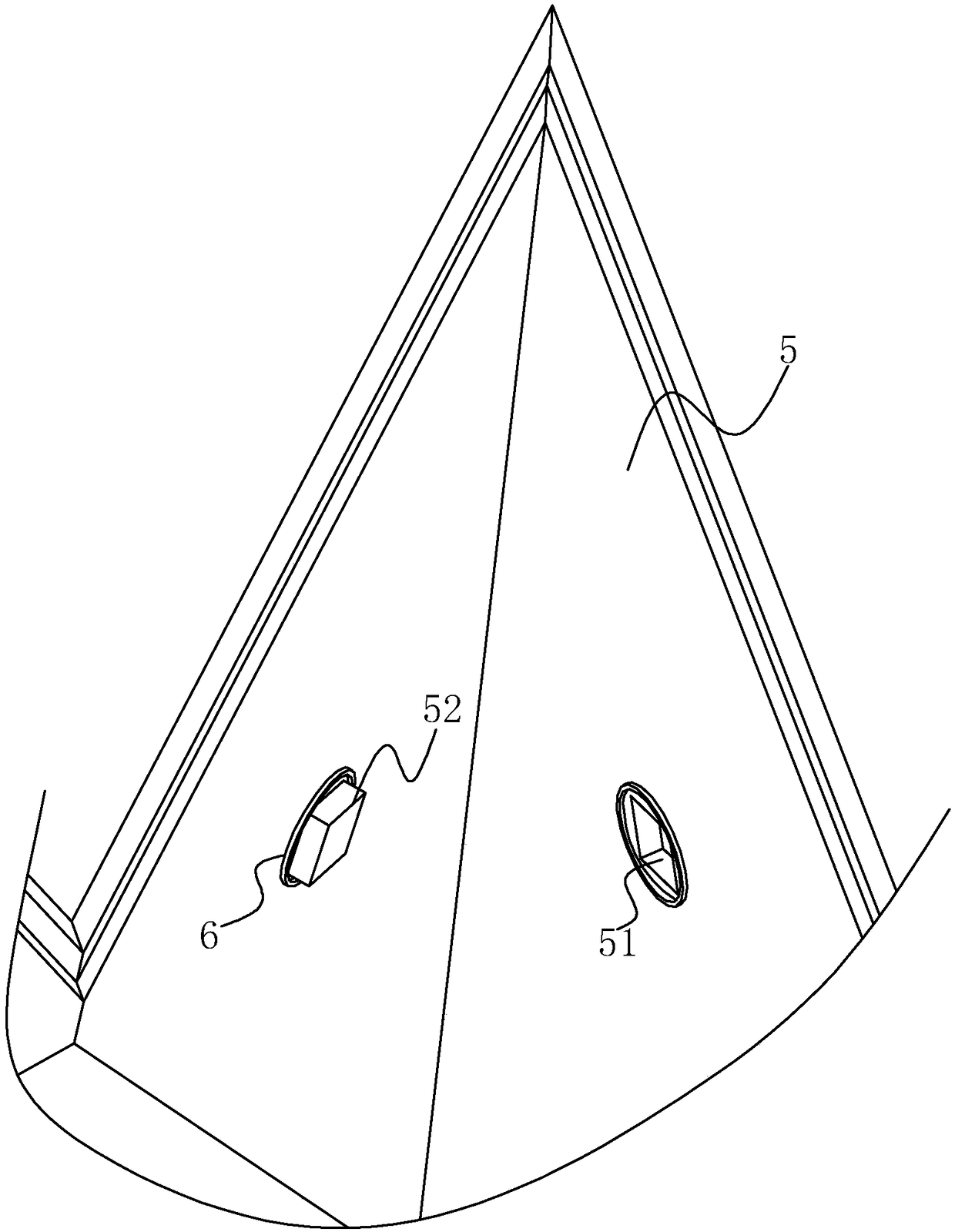

[0057] A box such as figure 2 As shown, it is assembled from the modified tear-resistant and water-resistant light-coated white-faced kraft cardboard in the above scheme. The packaging box includes six groups of 12-piece packaging boxes with lightly coated white-faced kraft cardboard for sealing 5, combined with image 3 The sealing part 5 is formed on the side of the bottom layer 3 close to the waterproof layer 4 and has a groove 51 and a protrusion 52 that are inserted into each other through a mould, so as to realize the rapid sealing of the modified tear-resistant and water-resistant light-coated white-faced kraft cardboard. Dislocation is not easy to occur when hot-melt sealing is performed, which affects the aesthetics of the seal;

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com