An Atomic Magnetic Microscopy Method Based on Cavity Resonance and Magnetic Concentration Structures

A magnetic aggregation, atomic technology, applied in the size/direction of the magnetic field, measuring magnetic variables, electromagnetism and other directions, can solve the problems of reducing the magnetic field sensitivity, sample magnetic field attenuation, etc., to achieve shortened settling time, enhanced signal contrast, high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

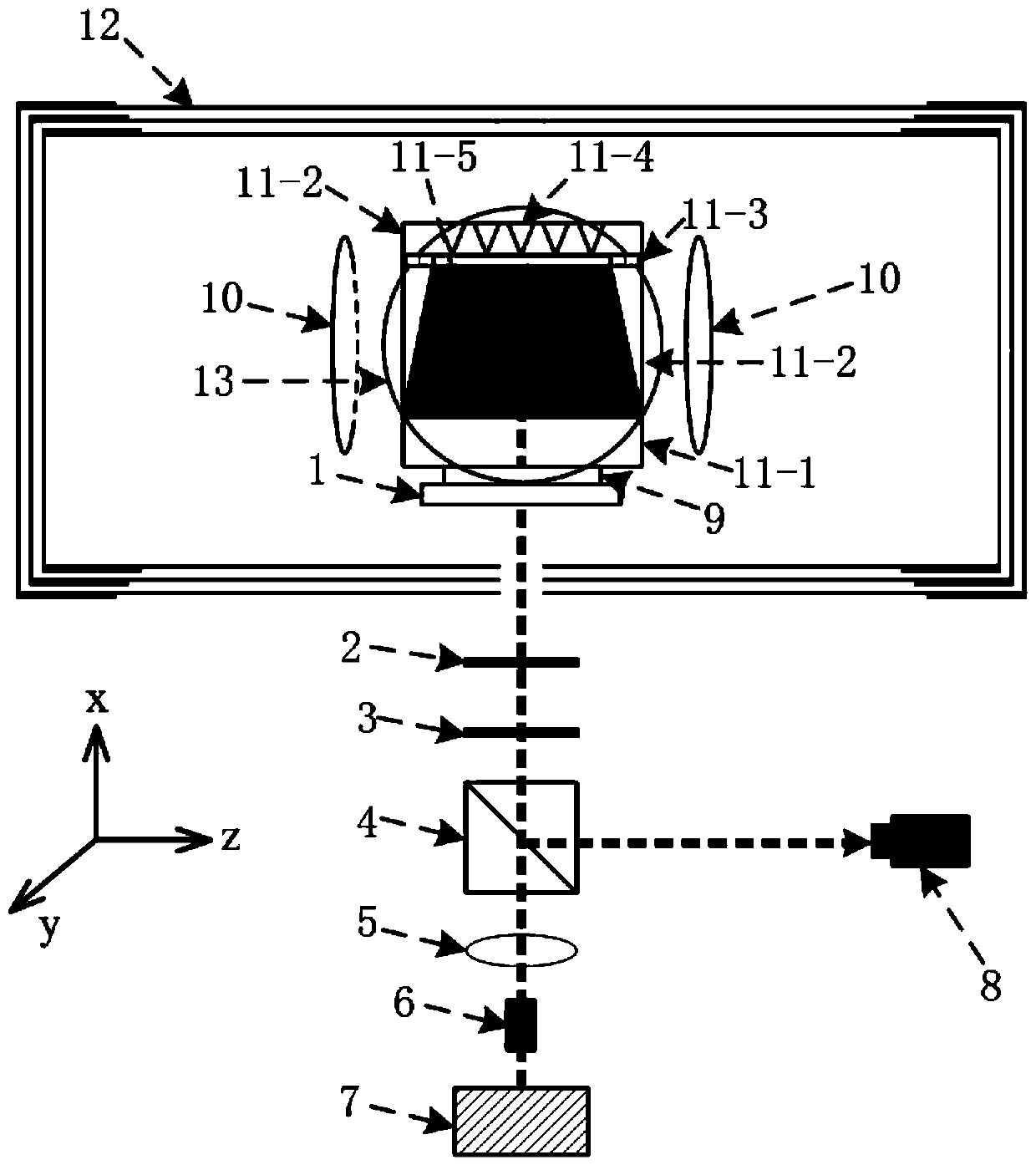

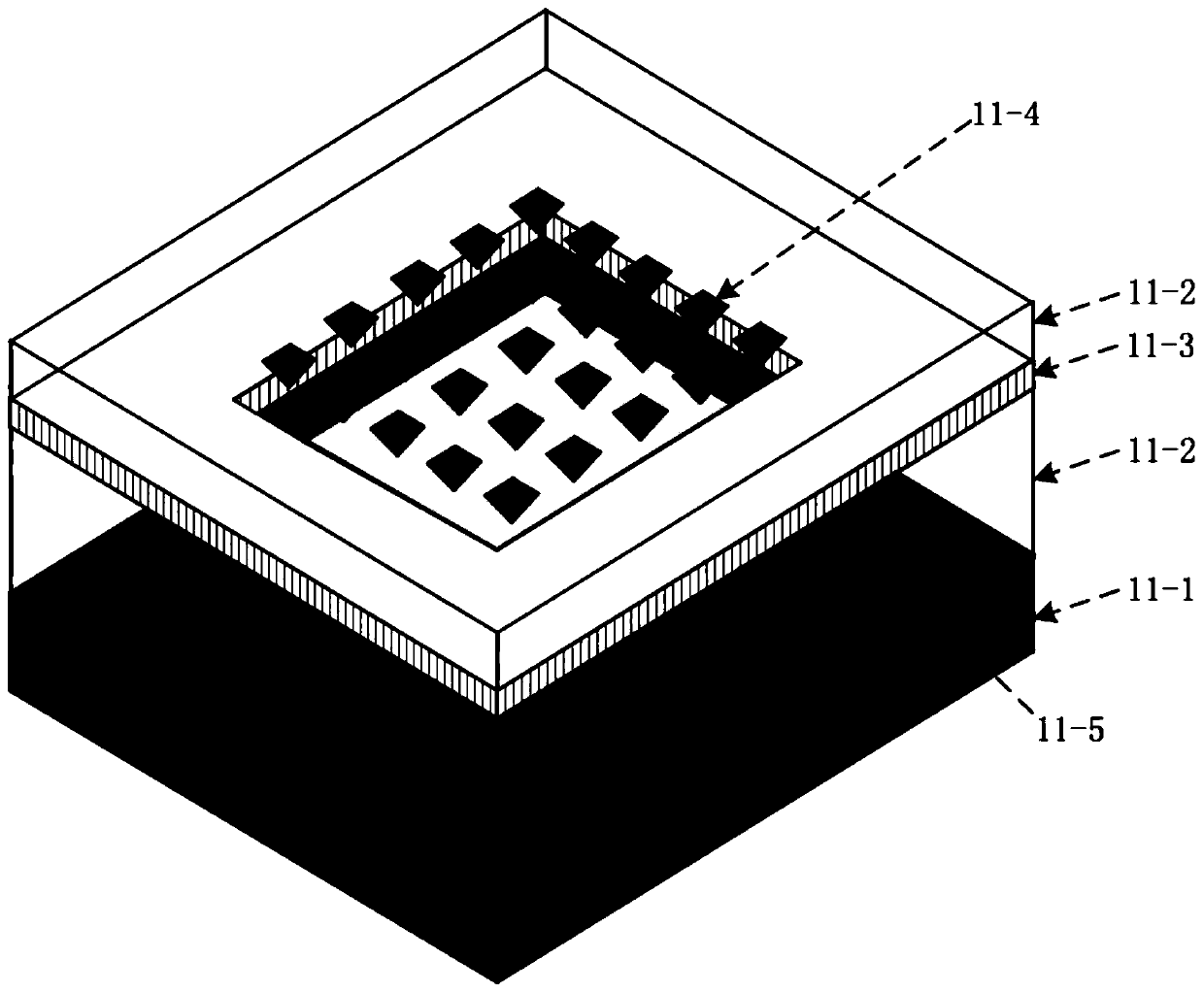

[0033] Such as figure 1 and figure 2 As shown, an atomic magnetic microscopy method based on cavity resonance and magnetic concentration structure, the device used in this method includes a short pulse laser 7, an optical isolator 6, a collimator lens 5, a broadband beam splitter prism 4, and a Glan-Taylor prism 3 , a quarter-wave plate 2, a concave mirror 1, an annular piezoelectric ceramic 9, a magnetic shield barrel 12, a magnetically concentrated atom gas chamber 11, a z-direction magnetic field coil 10, a y-direction magnetic field coil 13 and a CCD detector 8, using A short-pulse laser 7 with a wavelength of 894.5nm is used for pumping and detecting alkali metal cesium atoms at the same time. The pulse power of the laser is 100W; the pulsed laser passes through the optical isolator 6, collimator lens 5, broadband beam splitter 4, and Gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com