Device for measuring the depth of a weld seam in real time

A welding seam depth and equipment technology, which is applied in the field of equipment for real-time measurement of welding seam depth, can solve problems such as inability to provide depth information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

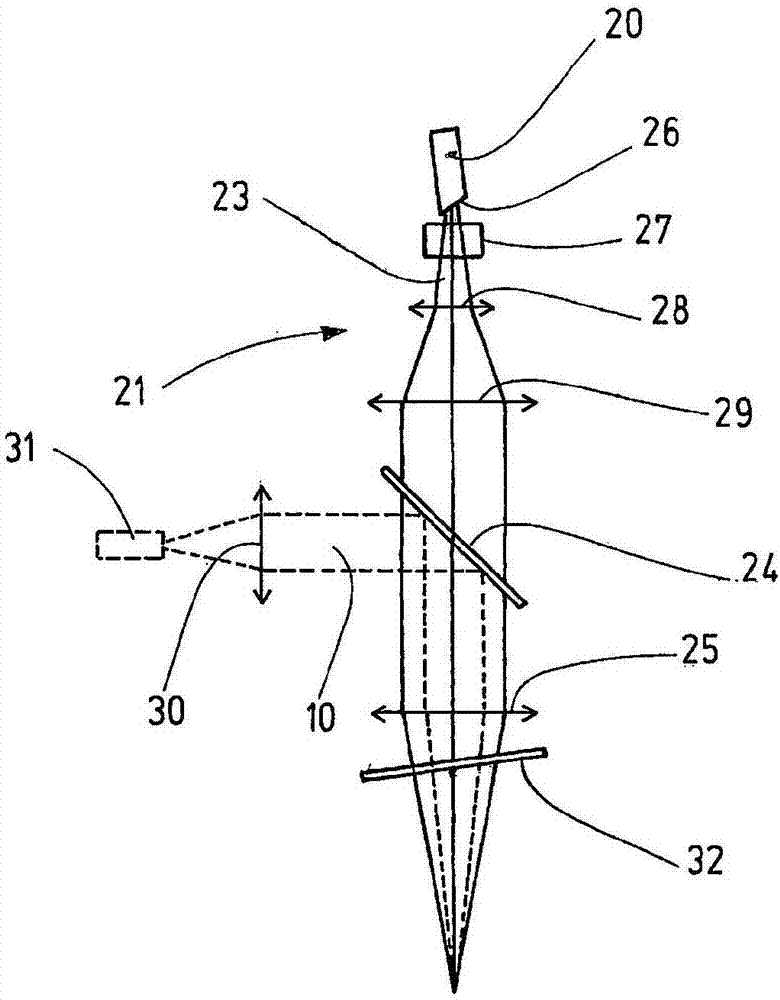

[0045] According to the invention, an optical system, hereinafter referred to as a collimation module, is provided in order to focus the measuring light of the measuring system into the locking hole through the welding head and redirect the measuring light reflected at the bottom of the locking hole into the measuring system.

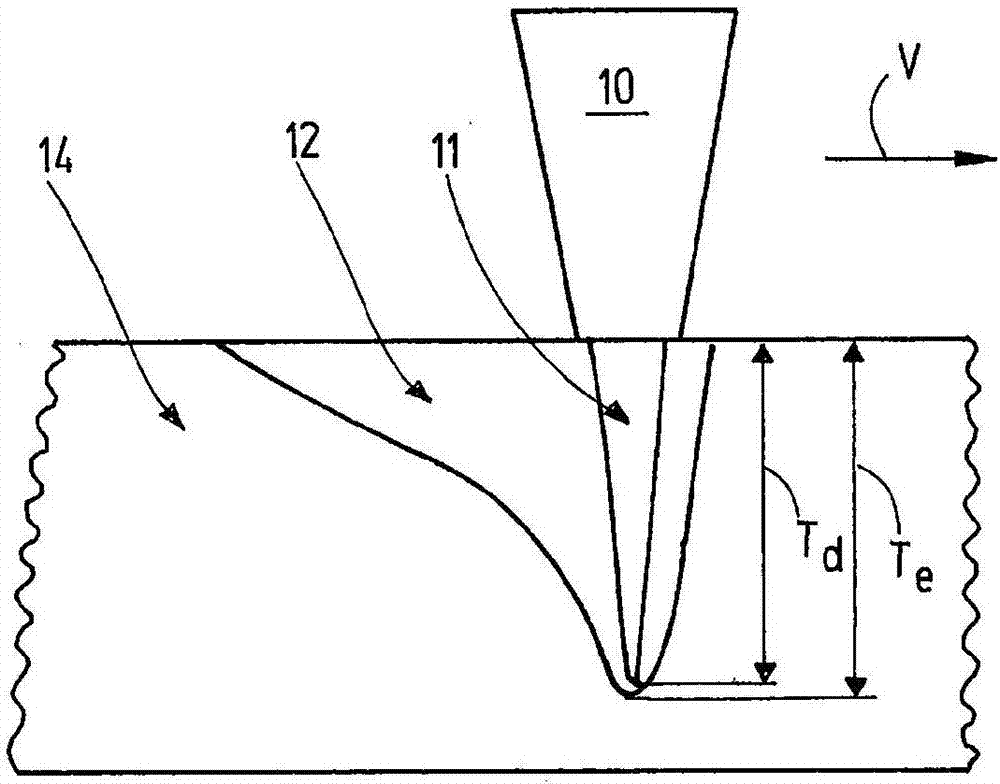

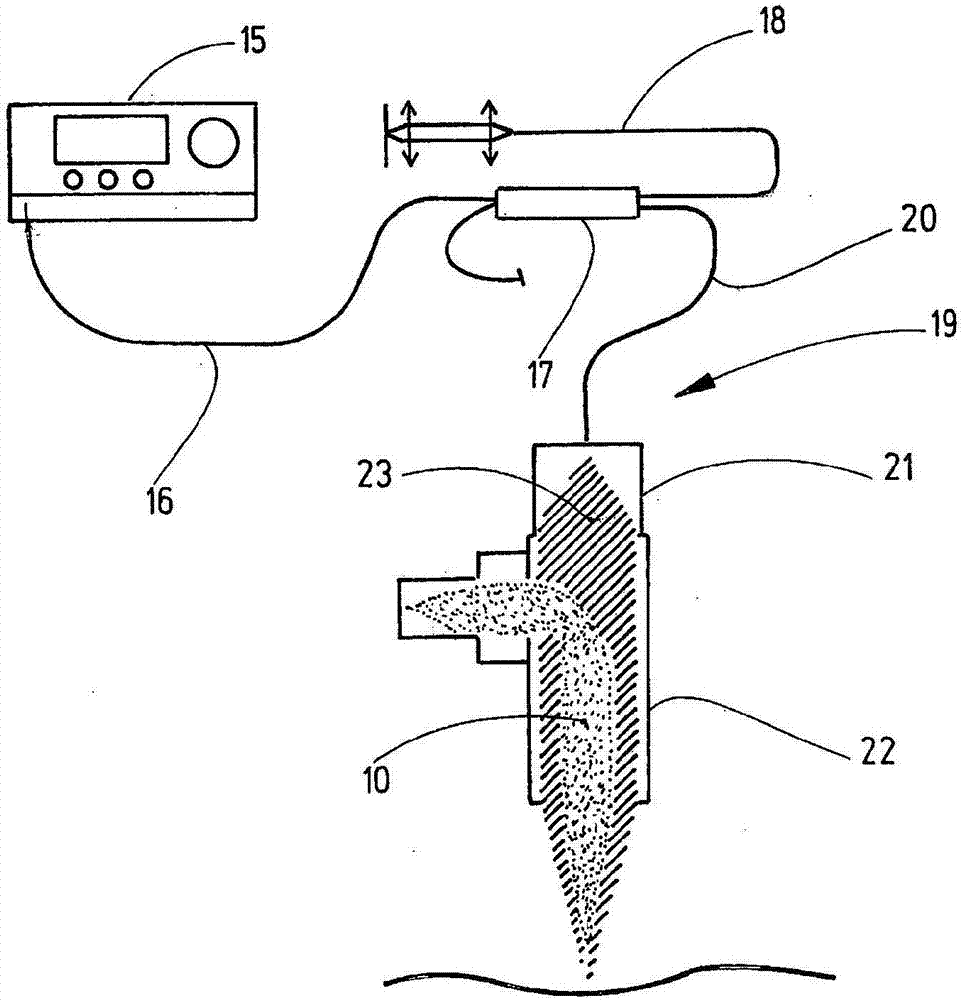

[0046] figure 2 The complete apparatus for real-time determination of keyhole depth is shown. The determination or measurement of the keyhole depth Td is based on optical coherence tomography, which utilizes the coherence properties of light by means of an interferometer. For this purpose, the evaluation unit 15 contains a broadband light source (Superlumineszenzdiode, SLD) which couples the measuring light into the optical waveguide 16 . In a beam splitter 17 , preferably with a fiber optic coupler, the measurement light is split into a reference arm 18 and a measurement arm 19 , which has an optical waveguide 20 , a collimation module 21 and a weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com