Method for preparing high-density electronic-grade semiconductor-purity super-long horizontal nanotube array

A nanotube array and semiconductor technology, which is applied in the direction of carbon nanotubes, nanocarbon, nanotechnology, etc., can solve the problems that the density cannot reach high current output carbon-based electronic devices, and there is a big gap in the purity of electronic grades, etc., to achieve broad commercial The effect of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

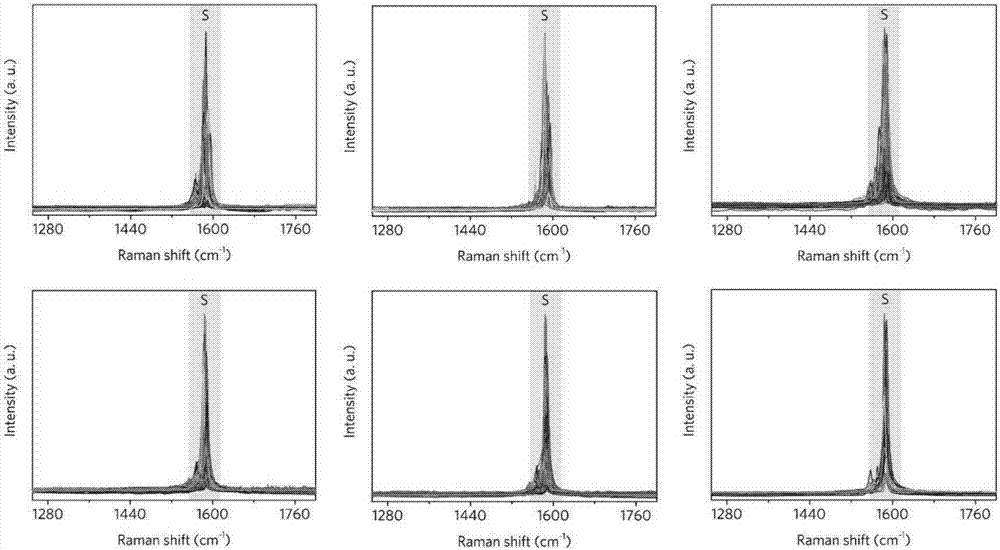

[0059] Example 1: Preparation and characterization of electronic-grade pure semiconducting ultra-long horizontal carbon nanotube arrays

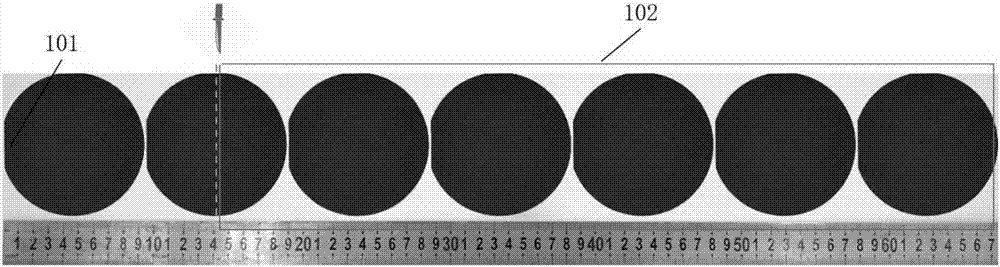

[0060] (1) Seven pieces of Si / SiO with a diameter of 10 cm are placed continuously in a cube-shaped quartz reactor 2 Wafer, with a total length of 70cm, such as figure 1 As shown, 0.05mol / L FeCl 3 Ethanol solution imprinted on the first Si / SiO 2 base front end (101);

[0061] (2) In the reactor, pass into the mixed gas (Ar:H of the argon gas of 220sccm) and hydrogen 2 =1:2, v / v) as a protective gas, and start to heat up. When the temperature rises to 1010°C, keep the temperature constant for 20min, then enter the reaction stage, and feed 160sccm methane and hydrogen gas mixture (H 2 :CH 4 =2.1:1, v / v), the reaction time continues to enter cooling stage after 30min; 2 =1:2, v / v), to prevent the carbon tube from being ablated during the cooling process;

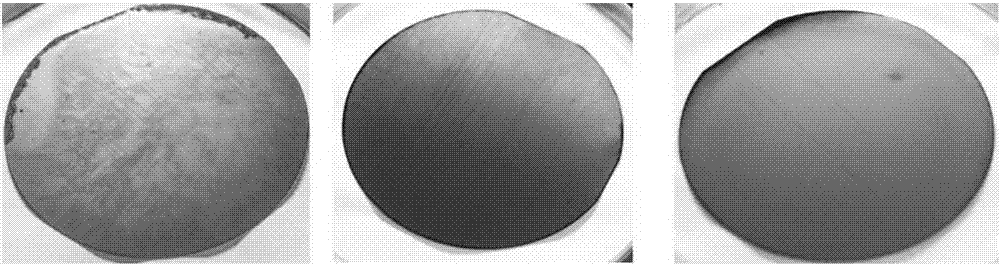

[0062] (3) When the temperature drops to room temperature, remove all Si / SiO 2 wa...

Embodiment 2

[0071]Example 2: Repeated growth improves the array density of electronic-grade purity semiconducting ultra-long horizontal carbon nanotubes

[0072] (1) Spread 0.3g FeCl upstream of the cube-shaped reactor airflow 3 Catalyst powder, feed the mixed gas of the argon of 200sccm and hydrogen (Ar:H in the reactor 2 =1:2, v / v) as a protective gas, and start to heat up, when the temperature rises to 1000°C, enter the cooling stage after constant temperature for 20min, and open the reactor when it drops to room temperature;

[0073] (2) 6 pieces of Si / SiO with a size of 5×8cm are placed continuously in the reactor 2 substrate, the growth direction of carbon nanotubes is along the width direction of the substrate, and 0.03mol / L FeCl 3 Ethanol solution imprinted on the first Si / SiO 2 basal front;

[0074] (3) Into the reactor, a mixture of argon and hydrogen of 200 sccm (Ar:H 2 =1:2, v / v) as a protective gas, and start to heat up. When the temperature rises to 1000°C, keep the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com