A kind of hydrophobic silicon dioxide modified rubber and its preparation method

A technology of hydrophobic silica and modified rubber, applied in the field of modified rubber materials, can solve the problems of low modification effect of silica particles, ineffective distribution of coupling agent, and reduced overall performance of rubber, and achieve good moisture resistance. Slip and grip, good economy, good anti-skid and wear-resistant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

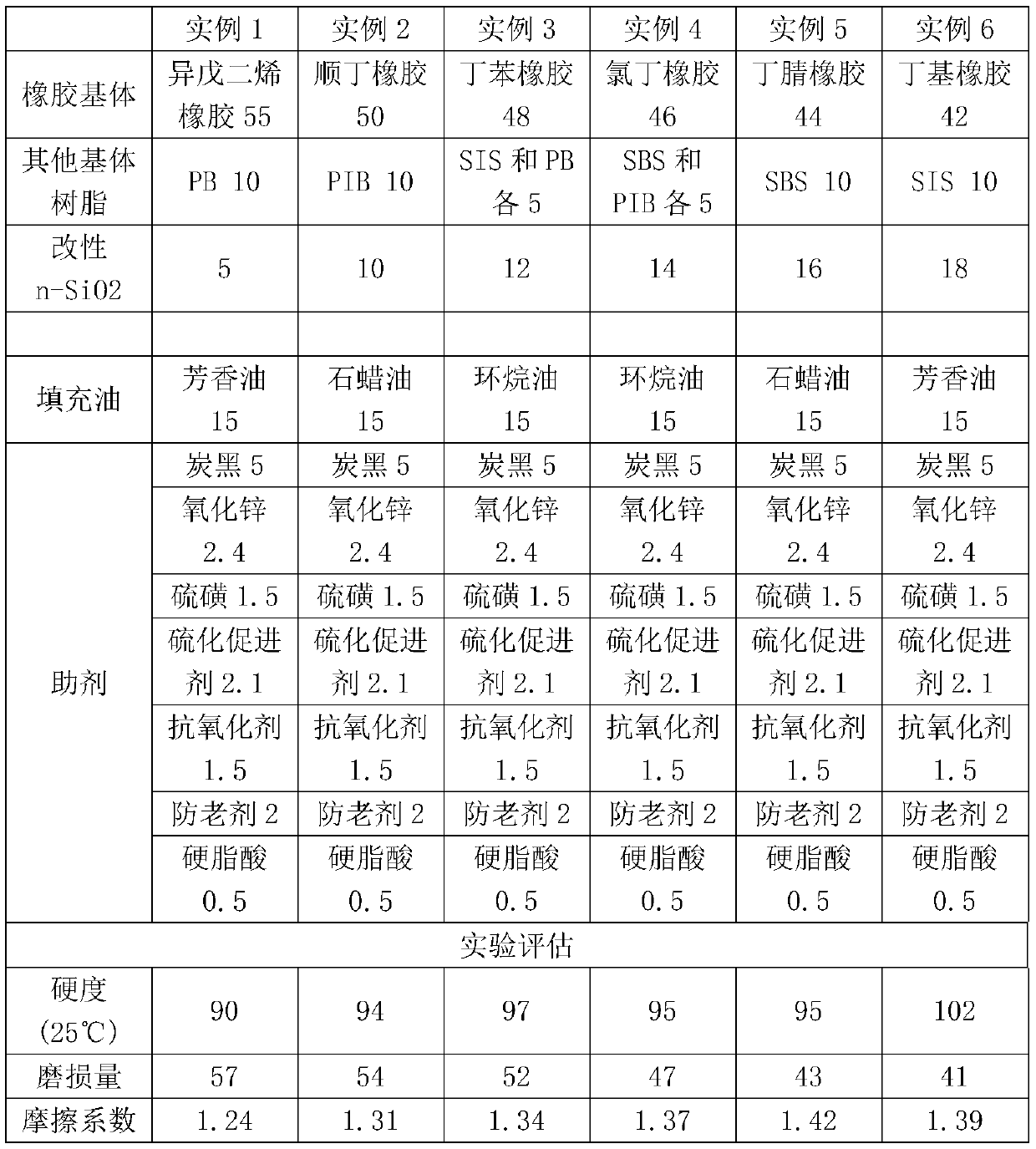

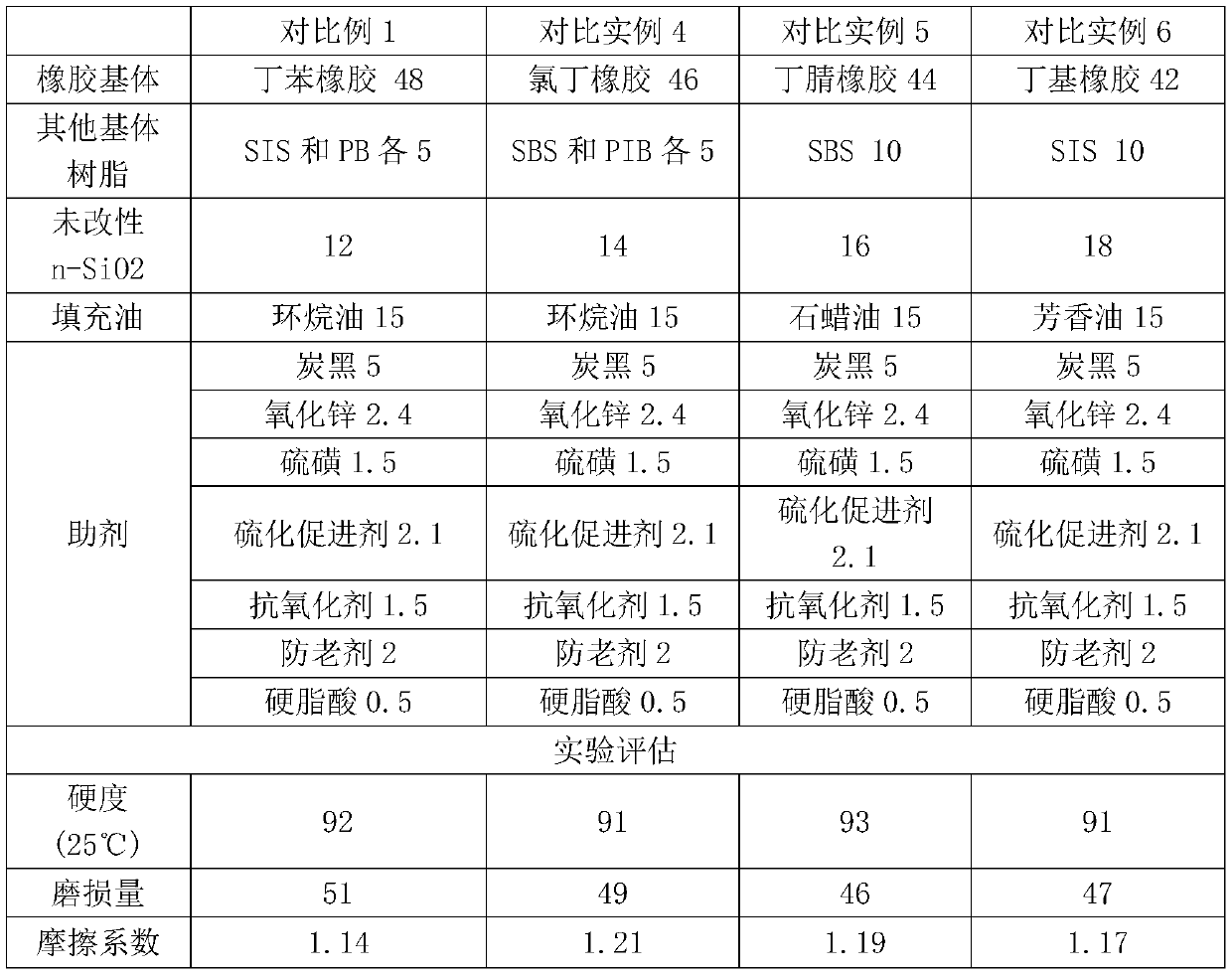

Embodiment 1

[0030] 55wt% isoprene rubber, 10wt% polybutene, 5wt% modified nano silica (modified SiO 2 A), 15wt% aromatic oil, 5wt% carbon black, 2.4wt% zinc oxide, 1.5wt% sulfur, 2.1wt% vulcanization accelerator, 1.5wt% antioxidant, 2wt% antioxidant, 0.5wt% stearic acid;

[0031] First, 55wt% of the rubber matrix was milled for 0.5 hour on a 50-80°C mill, and then 5wt% of the modified nano-silica (modified SiO 2 A) Add kneading and mixing for 15 minutes, control the temperature below 100°C, then take out the sheet, and move it to the internal mixer, then add 10wt% polybutene, 2.4wt% zinc oxide, 2wt% anti-aging agent, 1.5wt% % antioxidant, 1.5wt% sulfur, 2.1wt% vulcanization accelerator, 5wt% carbon black, finally add 15wt% aromatic oil and masticate for 30min, the banburying temperature is between 100-120°C; sliced and packaged for later use;

[0032] After the prepared rubber sheet was parked at room temperature for 8 hours, according to the "hardness test method of vulcanized rubber...

Embodiment 2

[0034] 50wt% butadiene rubber, 10wt% polyisobutylene, 10wt% modified nano silica (modified SiO 2 A), 15wt% paraffin oil, 5wt% carbon black, 2.4wt% zinc oxide, 1.5wt% sulfur, 2.1wt% vulcanization accelerator, 1.5wt% antioxidant, 2wt% antioxidant, 0.5wt% stearic acid;

[0035] First, 50wt% butadiene rubber matrix was milled for 0.5 hour on a 50-80°C open mill, and then 10wt% modified nano-silica (modified SiO 2A) Add kneading and mixing for 15 minutes, control the temperature below 100°C, then take out the sheet, and move it to the internal mixer, then add 10wt% polyisobutylene, 2.4wt% zinc oxide, 2wt% anti-aging agent, 1.5wt% Antioxidant, 1.5wt% sulfur, 2.1wt% vulcanization accelerator, 5wt% carbon black, and finally add 15wt% paraffin oil for masticating for 30 minutes, and the banburying temperature is between 100-120°C; and packaged for later use;

[0036] After the prepared rubber sheet was parked at room temperature for 8 hours, according to the "hardness test method of ...

Embodiment 3

[0038] 48wt% styrene-butadiene rubber, polybutylene and styrene-isoprene-styrene each 5wt%, 12wt% modified nano silica (modified SiO 2 A), 15wt% naphthenic oil, 5wt% carbon black, 2.4wt% zinc oxide, 1.5wt% sulfur, 2.1wt% vulcanization accelerator, 1.5wt% antioxidant, 2wt% antioxidant, 0.5wt% stearic acid;

[0039] First, the 48wt% styrene-butadiene rubber matrix was milled for 0.5 hour on a 50-80°C open mill, and then 12wt% modified nano-silica (modified SiO 2 A) Add in milling and mixing for 15 minutes, control the temperature below 100°C, then take out the sheet, and move it to the internal mixer, then add polybutene and styrene-isoprene-styrene respectively 5wt%, 2.4 wt% zinc oxide, 2wt% antioxidant, 1.5wt% antioxidant, 1.5wt% sulfur, 2.1wt% vulcanization accelerator, 5wt% carbon black, finally add 15wt% naphthenic oil and masticate for 30min, banburying temperature is 100- Between 120°C; finally transferred to the open mill to produce flakes and packaged for later use;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com