Preparation method of graphene-elastic polyester in-situ polymerized compound functional fibers

An in-situ polymerization and elastic polyester technology, applied in the field of fiber materials, can solve problems such as solvent residues, and achieve the effects of improved elongation at break, good effect and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

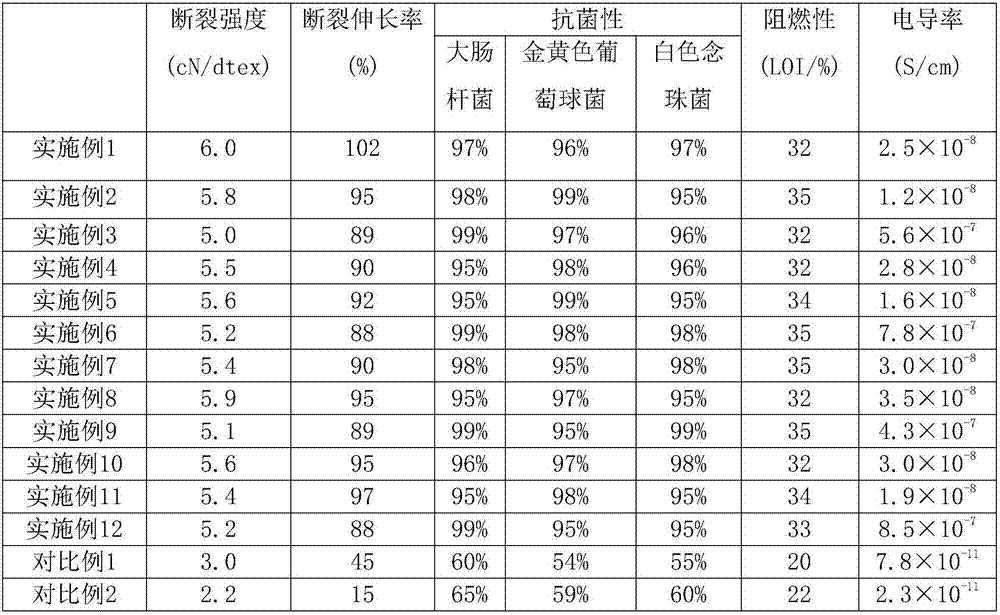

[0035] This example provides a method for in-situ polymerization and compounding of graphene and new polyester to obtain graphene-polyester composite chips, and then melt spinning to prepare functional fibers. The present invention adopts the in-situ polymerization and compounding process to prepare graphene-polyester composite slices and obtains graphene composite functional fibers by melt spinning, compared with the traditional compounding method in which polyester slices and graphene are directly mixed by mechanical grinding and stirring. In terms of the method, the composite method of the present invention has reached the molecular level, and has an obvious reinforcing effect on the material, and the prepared composite chips are generally applicable to almost all melt spinning platforms.

[0036] The preparation method is as follows:

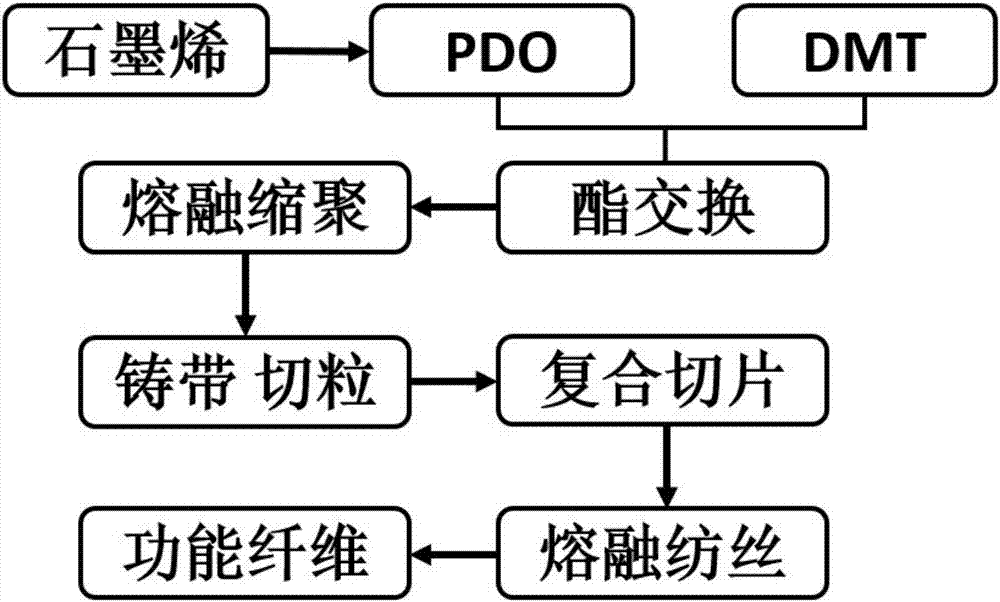

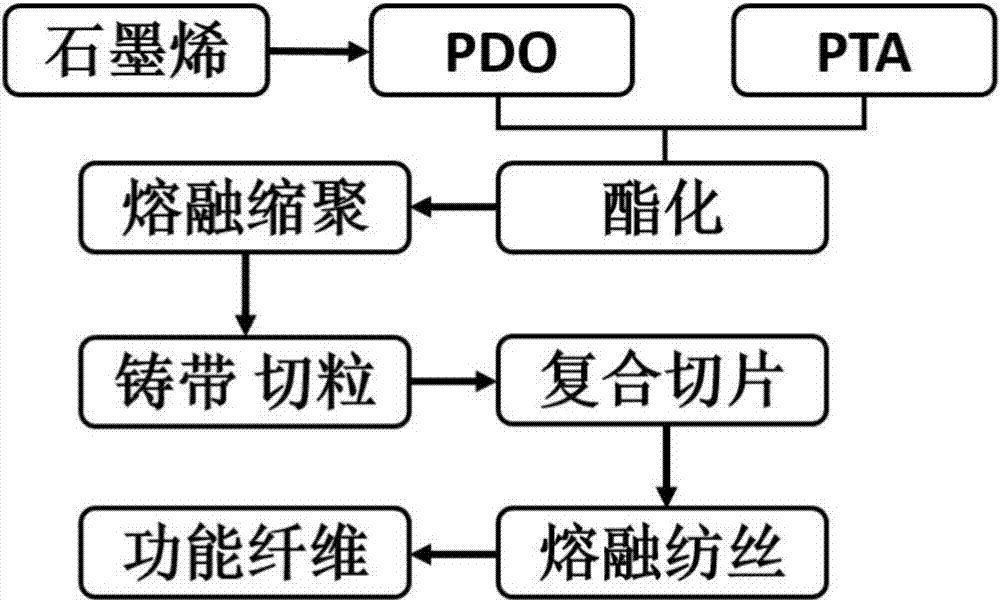

[0037] Composite chip preparation method 1: the preparation scheme of the transesterification-polycondensation method of graphene / PTT (such...

Embodiment 1

[0050] Example 1, the graphene-polyester composite high elastic functional fiber obtained according to the preparation method 1 is recorded as Example 1.

Embodiment 2

[0051] Embodiment 2, the difference with embodiment 1 is: take 0.0346g graphene and add in 152g 1,3-propanediol (PDO), mix by solution, at 170~220 ℃, under inert gas protection, with 194g p-benzene Dimethyl dicarboxylate (DMT) undergoes a transesterification reaction to form the polyester oligomer trimethylene terephthalate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com