Pulse plasma thruster based on capillary discharging

A technology of pulsed plasma and plasma, which is applied in the field of plasma thrusters, can solve the problems of low acceleration efficiency of pulsed plasma thrusters, affecting the energy conversion efficiency of thrusters, and low utilization of working fluid, so as to improve energy utilization efficiency , overall safety and reliability improvement, insulation structure simplification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

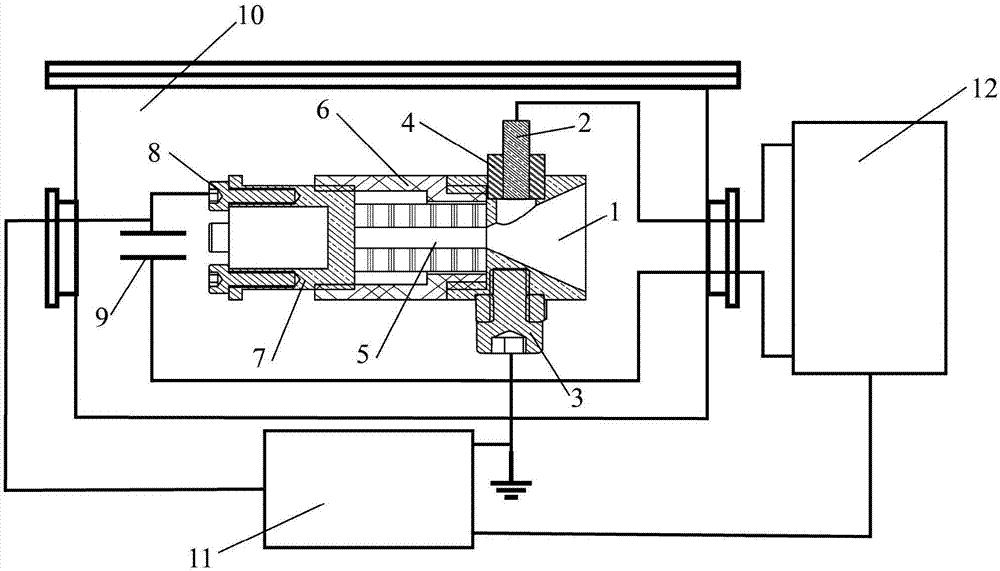

[0020] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

[0021] In one embodiment, the present invention discloses a pulsed plasma thruster based on capillary discharge,

[0022] The thruster includes: a power processing unit, a semiconductor spark plug, an ignition circuit, a main discharge circuit and a propellant working medium;

[0023] The power processing unit is used to provide the voltage required for the thruster to work, charge the main capacitor in the main discharge circuit and supply power to the ignition circuit;

[0024] The ignition circuit is used to output pulse high voltage to cause surface discharge of semiconductor spark plug to generate initial charged particles;

[0025] The initial charged particles generated by the semiconductor spark plug enter the propellant working fluid, and generate plasma through continuous impact ionization;

[0026] The propellant working medium is capillary type, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com