Potassium manganese oxide for potassium ion battery positive electrode material and preparation method of potassium manganese oxide

A battery positive electrode and manganese oxide technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of high cost, high temperature, and unfavorable large-scale production, and achieve low cost, uniform chemical composition, and cycle capacity stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

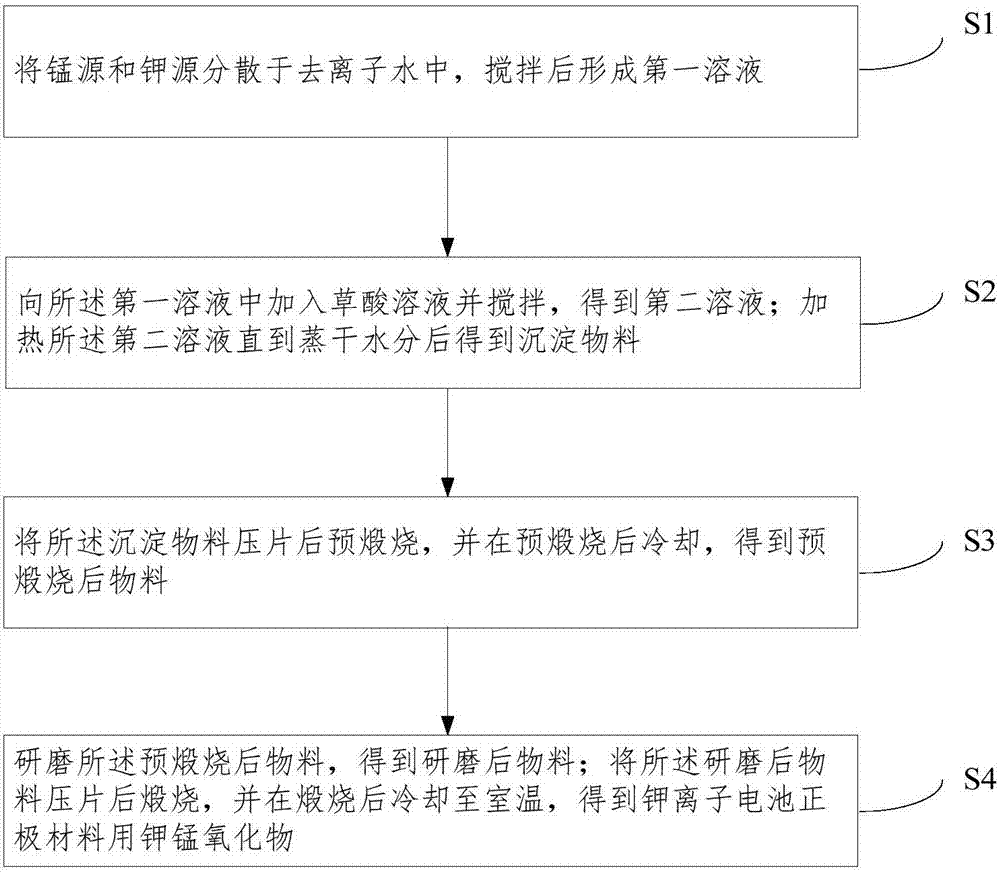

[0035] First aspect, such as figure 1 Shown, the preparation method of potassium manganese oxide for the positive electrode material of potassium ion battery of an embodiment of the present invention, comprises the following steps:

[0036] Step S1: disperse manganese source and potassium source in deionized water, form the first solution after stirring;

[0037] Step S2: adding oxalic acid solution to the first solution and stirring to obtain a second solution; heating the second solution until the water is evaporated to obtain a precipitated material;

[0038] Step S3: pre-calcining the precipitated material after tableting, and cooling after pre-calcining to obtain a pre-calcined material;

[0039] Step S4: Grinding the pre-calcined material to obtain the ground material; pressing the ground material into tablets and calcining, and cooling to room temperature after calcining to obtain potassium manganese oxide for positive electrode materials of potassium ion batteries.

...

Embodiment 1

[0057] Mix and disperse potassium nitrate and manganese nitrate in deionized water at a molar ratio of 0.3:1, stir vigorously to form a transparent solution, then add 1mol / L oxalic acid solution to the transparent solution, and place it in a water bath at 80°C , evaporated to dryness, placed in an oven, and dried overnight to obtain a white precipitate material; the obtained white precipitate material was pressed into tablets and placed in an air atmosphere, and the temperature was raised to 450°C at a rate of 3°C / min, and kept at a constant temperature of 450°C Pre-calcined for 6 hours to obtain the pre-calcined material. The pre-calcined material was ground and re-pressed into tablets, and calcined at a constant temperature of 900°C for 15 hours, and then naturally cooled to room temperature with the furnace.

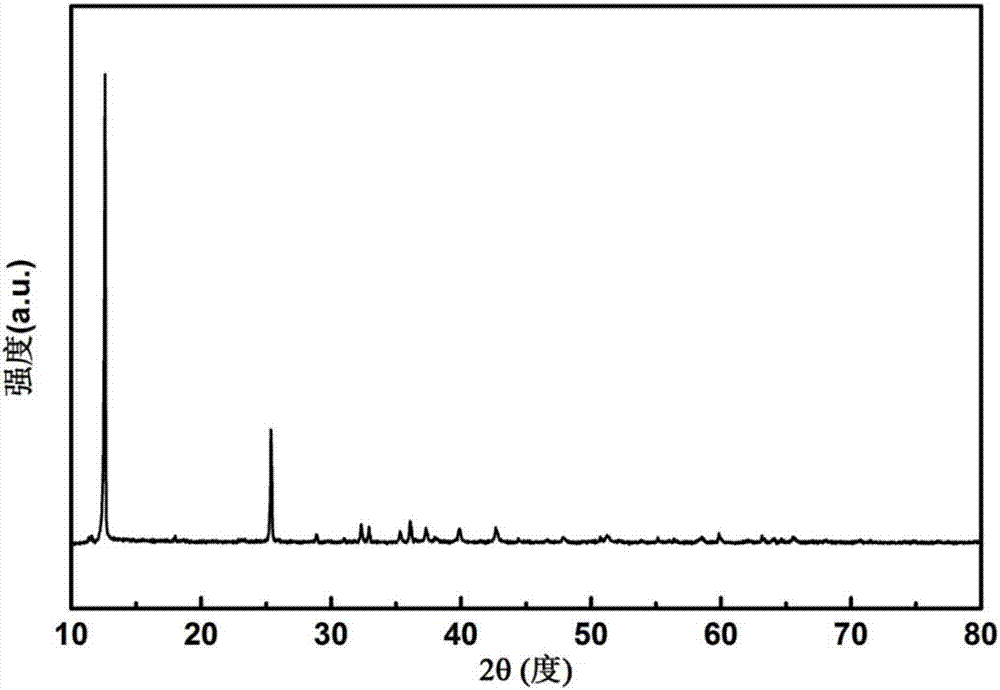

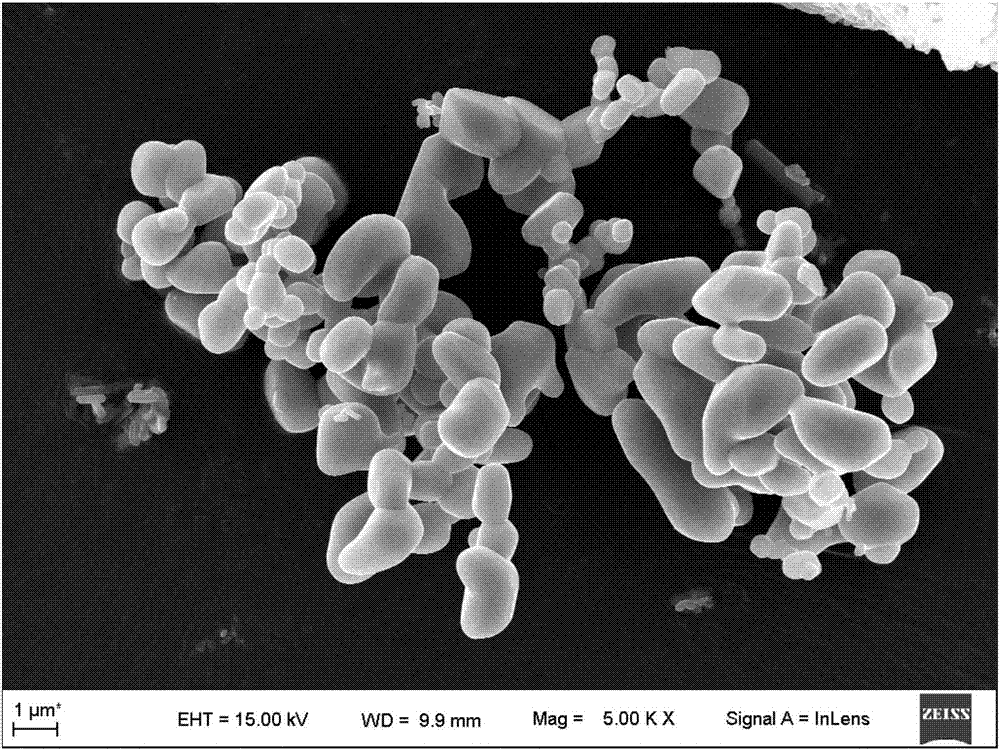

[0058] The nominal composition of the resulting product is K 0.3 MnO 2 , X-ray diffraction analysis was performed on the prepared cathode material. according to ...

Embodiment 2

[0066] Mix and disperse potassium acetate and manganese acetate in deionized water at a molar ratio of 0.7:1, stir vigorously to form a transparent solution, then add 1mol / L oxalic acid solution to the transparent solution, and place it in a 90°C water bath , after evaporating the water, put it in an oven and dry it overnight to obtain a white precipitated material; press the obtained white precipitated material into tablets, place it in an air atmosphere, raise the temperature to 350°C at a rate of 2°C / min, and keep the constant temperature at 350°C Pre-calcined for 6 hours to obtain the pre-calcined material. The pre-calcined material was ground and re-pressed into tablets, calcined at a constant temperature of 750°C for 15 hours, and then cooled to room temperature in liquid nitrogen. The nominal composition of the resulting product is K 0.7 MnO 2 .

[0067] A potassium ion battery was prepared according to the method in Example 1 and a charge and discharge test was perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com