Double-drum and double-mass vibration mill adopting variable-pitch non-closed-coil springs and media in mixed density

A technology of mixing density and variable pitch, applied in grain processing and other directions, can solve the problems of high noise and low efficiency, and achieve the effect of reducing vibration impact, reducing energy consumption and good energy saving.

Inactive Publication Date: 2017-08-29

NANJING INST OF TECH

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

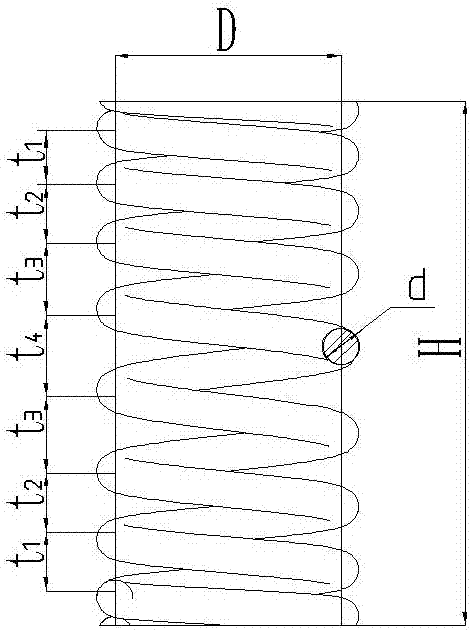

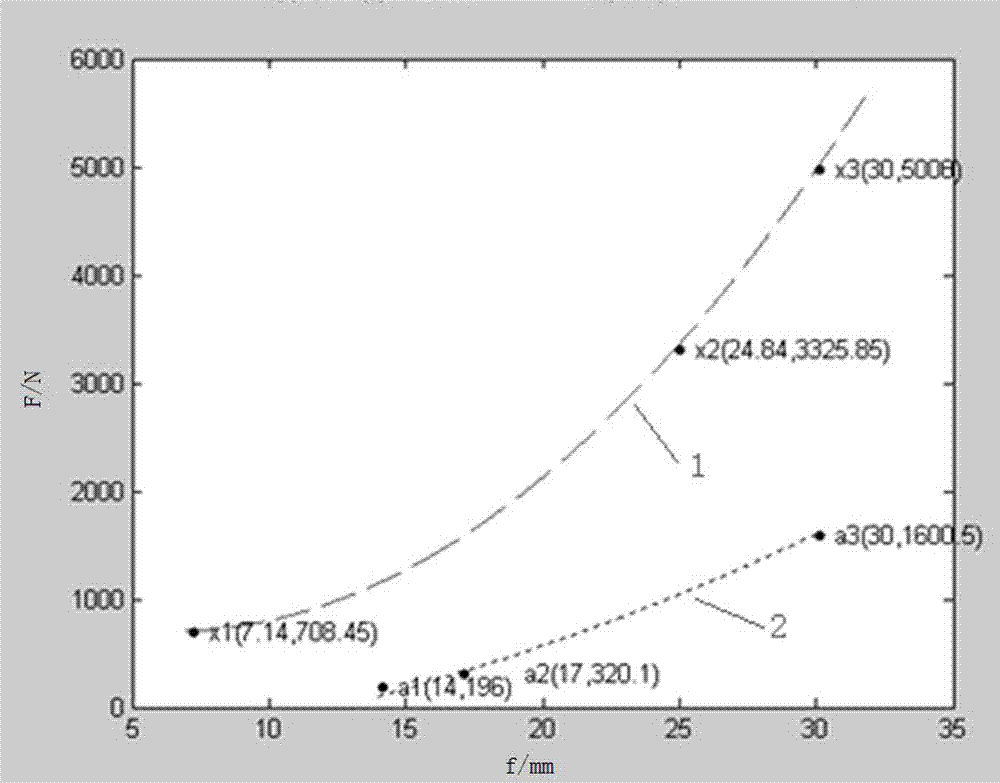

The invention provides a variable-pitch non-coil spring and mixed-density medium double-tube dual-mass vibration mill, which has the technical characteristics of dual-mass. The main vibration spring is a variable-pitch non-coil spring, and the vibration isolation spring is a rubber canvas composite spring. The main-vibration isolation springs are all variable stiffness; in order to increase the impact, extrusion, shearing, and collision energy of the grinding media balls in the cylinder during relative motion, the optimal setting of the mixed density medium ratio is implemented, which is different from the existing widely used common Compared with the double-barrel vibratory mill system, it has the characteristics of high efficiency and low noise. It aims to effectively solve the technical bottleneck problems of high noise and low efficiency that have been pending in the existing vibratory mill.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

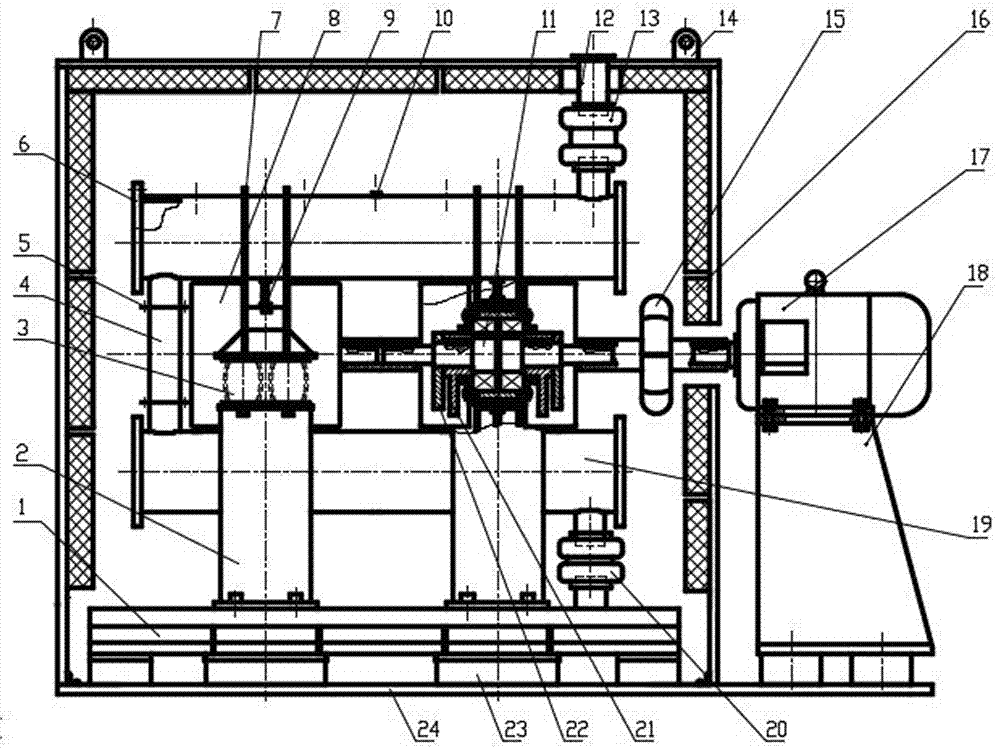

The invention discloses a double-drum and double-mass vibration mill adopting variable-pitch non-closed-coil springs and media in the mixed density. The vibration mill comprises a main vibration system and a vibration isolating system; the main vibration system comprises a motor controlled by a frequency converter and arranged on a motor support; a vibration exciter shaft is connected with an outer shaft of the motor through a coupling; the vibration exciter shaft is arranged on a machine seat; the machine seat of the vibration exciter shaft is fixedly connected between upper drum and a lower drum, and an upper mass is formed; the upper grinding drum and the lower grinding drum are arranged on the upper mass; a vibration exciter is mounted between connecting plates of the upper grinding drum and the lower grinding drum of the upper mass and becomes a vibration exciting source of the whole mill; the vibration isolating system comprises a lower mass connected with a main vibration spring group; the other end of the lower mass is connected with vibration isolating springs; and the vibration isolating springs are connected with a foundation through a base. The vibration mill has the characteristics of being capable of realizing ultrafine particle refining, realizing de-agglomeration and narrowing the powder product distributing zone, low in energy consumption, high in grinding efficiency, high in energy utilization rate, capable of realizing effective energy storage, saving energy, running stably and remarkably reducing the noise, good in vibration isolating effect and the like.

Description

Variable-pitch non-coil spring and mixed-density medium double-barrel double-mass vibration mill technical field The invention relates to a grinding equipment for vibration preparation of superfine powder of materials, which is a double-barrel two-mass vibratory mill with variable pitch non-coil springs and a medium of mixed density ratio, belonging to vibration utilization and powder grinding equipment. Interdisciplinary science and technology of body engineering. Background technique Vibrating mill is a vibrating mechanical equipment that uses the principle of vibration to complete the ultrafine grinding operation of materials. In the existing ultrafine powder preparation technology, vibrating mill and other preparation methods include gas phase synthesis, liquid phase synthesis, jet milling, Compared with the drum milling method, it has the advantages of high mechanical activity of the material, convenient purification, low cost, simple structure, and high efficiency. T...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B02C17/14B02C17/24

CPCB02C17/14B02C17/24

Inventor 杨小兰刘极峰刘扬正

Owner NANJING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com