Electrochemical electrode for detecting copper ions and preparation method and application thereof

An electrochemical and copper ion technology, applied in the field of electrochemical analysis and detection, can solve the problems of weak detection signal, low detection accuracy, weak activity, etc., and achieve the effects of high sensitivity, improved detection accuracy and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1) Gently wipe the surface of the glassy carbon electrode with wet lens tissue to remove dirt. Use 0.3μm and 0.05μm alumina polishing powder to polish the electrode into a "mirror surface" on the polishing cloth in turn, rinse the surface of the electrode with deionized water, and immerse the electrode in absolute ethanol and deionized water for ultrasonic cleaning for 2 to 3 minutes. Let it dry naturally, and use it as a conductive base material for later use;

[0049] 2) Prepare a solution, wherein: the concentration of carbon black is 0.35g / L, the concentration of graphene oxide is 0.2g / L, the solvent is deionized water, and ultrasonic treatment is performed for 90 minutes;

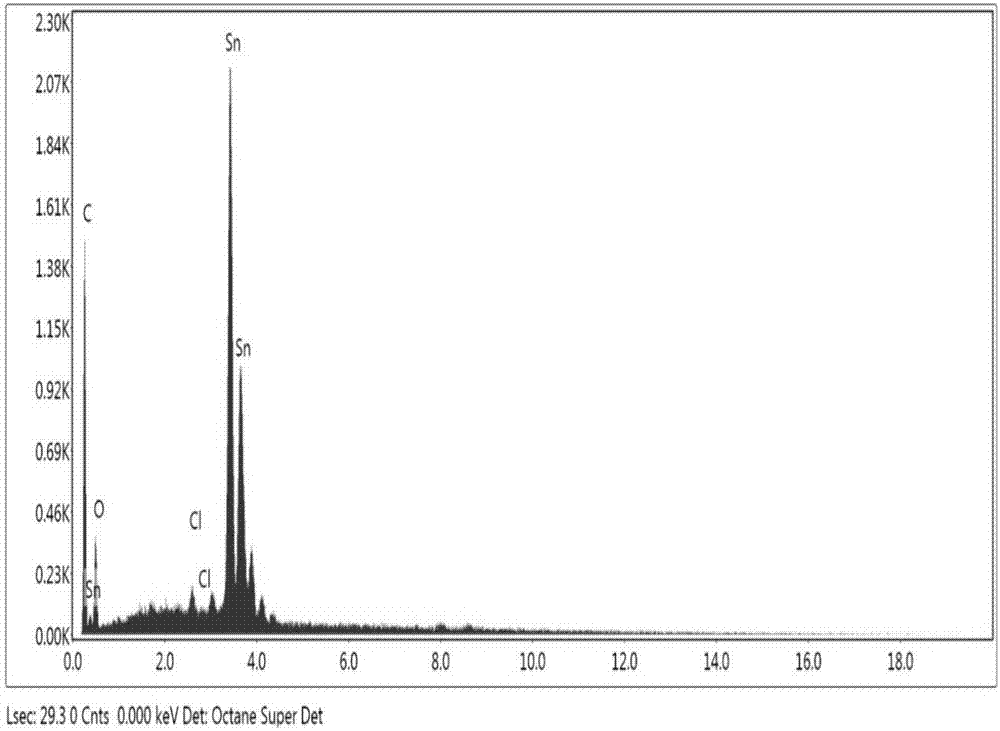

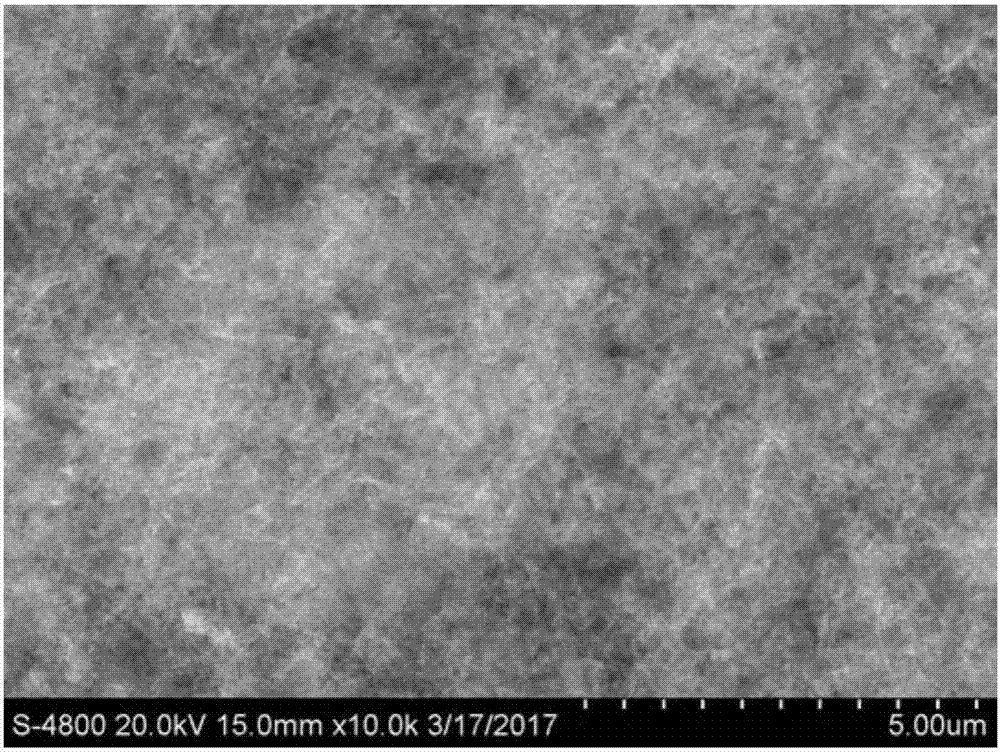

[0050] 3) 2.4g SnCl 4 ·5H 2 O was dissolved in 20 mL deionized water to prepare 0.24 M SnCl 4 solution, and 8 mL of the solution prepared in step 2) was added. The mixed solution was placed in a magnetic stirrer and stirred for 5 hours, then placed in a centrifuge for separation for 5 minute...

Embodiment 2

[0059] 1) Gently wipe the surface of the electrode with wet lens tissue to remove dirt. Use 0.3μm and 0.05μm alumina polishing powder to polish the electrode into a "mirror surface" on the polishing cloth in turn, rinse the surface of the electrode with deionized water, and immerse the electrode in absolute ethanol and deionized water for ultrasonic cleaning for 2 to 3 minutes. Let it dry naturally, and use it as a conductive base material for later use;

[0060] 2) Prepare a solution, wherein: the concentration of carbon nanotubes is 0.25g / L, the concentration of graphene oxide is 0.2g / L, the concentration of activated carbon is 0.01g / L, the solvent is deionized water, and ultrasonic treatment is performed for 90 minutes;

[0061] 3) 2.4gSnCl 4 ·5H 2 O was dissolved in 20 mL deionized water to prepare 0.24 M SnCl 4 solution, and 8 mL of the solution prepared in step 2) was added. The mixed solution was placed in a magnetic stirrer and stirred for 5 hours, then placed in a...

Embodiment 3

[0068] 1) Gently wipe the surface of the electrode with wet lens tissue to remove dirt. Use 0.3μm and 0.05μm alumina polishing powder to polish the electrode into a "mirror surface" on the polishing cloth in turn, rinse the surface of the electrode with deionized water, and immerse the electrode in absolute ethanol and deionized water for ultrasonic cleaning for 2 to 3 minutes. Let it dry naturally, and use it as a conductive base material for later use;

[0069] 2) Prepare the solution, wherein: the concentration of carbon black is 0.25g / L, the concentration of graphene oxide is 0.2g / L, the concentration of activated carbon is 6g / L, the solvent is deionized water, and ultrasonic treatment is performed for 90 minutes;

[0070] 3) 2.4gSnCl 4 ·5H 2 O was dissolved in 20 mL deionized water to prepare 0.24 M SnCl 4 solution, and 8 mL of the solution prepared in step 2) was added. The mixed solution was placed in a magnetic stirrer and stirred for 5 hours, then placed in a cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com