Preparation method of catalyst for synthesis of N-methylaniline and application

A methylaniline and catalyst technology, applied in the field of chemical technology, can solve the problems of dangerous inconvenience, inconvenience to use, etc., and achieve the effect of avoiding hydrogenation reduction pretreatment and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

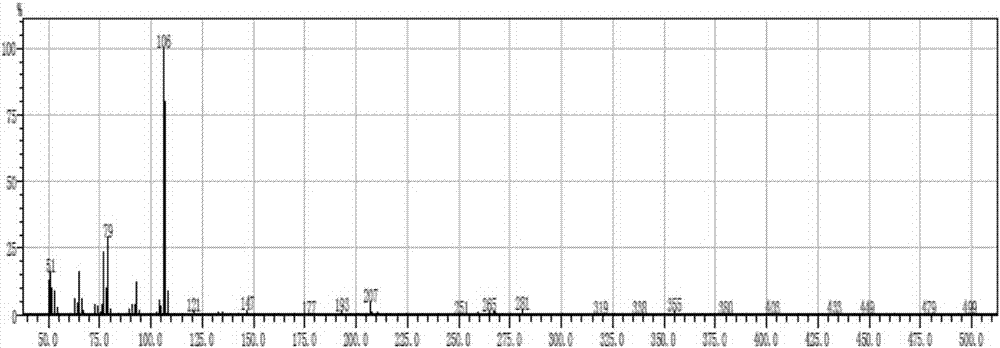

Image

Examples

Embodiment 1

[0018] (1) Accurately measure 87.5mL (0.00875mol) of 0.1mol / L copper nitrate aqueous solution, 262.5mL (0.02625mol) of 0.1mol / L zinc nitrate aqueous solution, 175mL (0.0175mol) of 0.1mol / L chromium nitrate and 0.1 Mix 525 mL (0.0525 mol) of mol / L aluminum nitrate thoroughly, take 0.1 mol / L sodium hydroxide aqueous solution as a precipitant, and use the co-precipitation method to allow the nitrate mixed solution and sodium hydroxide aqueous solution to react in a 60°C water bath to pH After reaching 10, age for 10 hours;

[0019] (2) centrifuging the aged system in step (1), washing the obtained filter cake until the pH value is 7 and drying at 80° C. under normal pressure for 10 hours to obtain a copper-zinc-chromium-aluminum quaternary coprecipitate;

[0020] (3) placing the co-precipitate obtained in step (2) in a 900°C muffle furnace for roasting for 6h, and cooling naturally;

[0021] (4) Mix the mixture obtained in step (3) with alumina, pseudoboehmite, and 15wt% nitric ...

Embodiment 2

[0025] (1) Accurately measure 116.7mL (0.01167mol) of 0.1mol / L copper nitrate aqueous solution, 233.3mL (0.02333mol) of 0.1mol / L zinc nitrate aqueous solution, 175mL (0.0175mol) of 0.1mol / L chromium nitrate and 0.1 Mix 525 mL (0.0525 mol) of mol / L aluminum nitrate thoroughly, take 0.1 mol / L sodium hydroxide aqueous solution as a precipitant, and use the co-precipitation method to allow the nitrate mixed solution and sodium hydroxide aqueous solution to react in a 60°C water bath to pH After reaching 10, age for 10 hours;

[0026] (2) centrifuging the aged system in step (1), washing the obtained filter cake until the pH value is 7 and drying at 80° C. under normal pressure for 10 hours to obtain a copper-zinc-chromium-aluminum quaternary coprecipitate;

[0027] (3) placing the co-precipitate obtained in step (2) in a 900°C muffle furnace for roasting for 6h, and cooling naturally;

[0028] (4) Mix the mixture obtained in step (3) with alumina, pseudoboehmite, and 15wt% nitric...

Embodiment 3

[0032] (1) Accurately measure 175mL (0.0175mol) of 0.1mol / L copper nitrate aqueous solution, 175mL (0.0175mol) of 0.1mol / L zinc nitrate aqueous solution, 175mL (0.0175mol) of 0.1mol / L chromium nitrate and 0.1mol / L 525 mL (0.0525 mol) of aluminum nitrate in L was fully mixed, and 0.1 mol / L sodium hydroxide aqueous solution was used as a precipitating agent, and the nitrate mixed solution and sodium hydroxide aqueous solution were reacted in a water bath at 60°C until the pH reached 10 by co-precipitation method. Afterwards, aging for 10 hours;

[0033] (2) centrifuging the aged system in step (1), washing the obtained filter cake until the pH value is 7 and drying at 80° C. under normal pressure for 10 hours to obtain a copper-zinc-chromium-aluminum quaternary coprecipitate;

[0034] (3) placing the co-precipitate obtained in step (2) in a 900°C muffle furnace for roasting for 6h, and cooling naturally;

[0035] (4) Mix the mixture obtained in step (3) with alumina, pseudoboeh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com