Novel door and window auxiliary frame and preparation method thereof

A technology for doors and windows and attached frames, which is applied in the field of new door and window attached frames and its preparation, which can solve the problems of low strength, heat resistance, energy saving and environmental protection, and achieve the effects of high tensile strength, good elasticity, and good light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

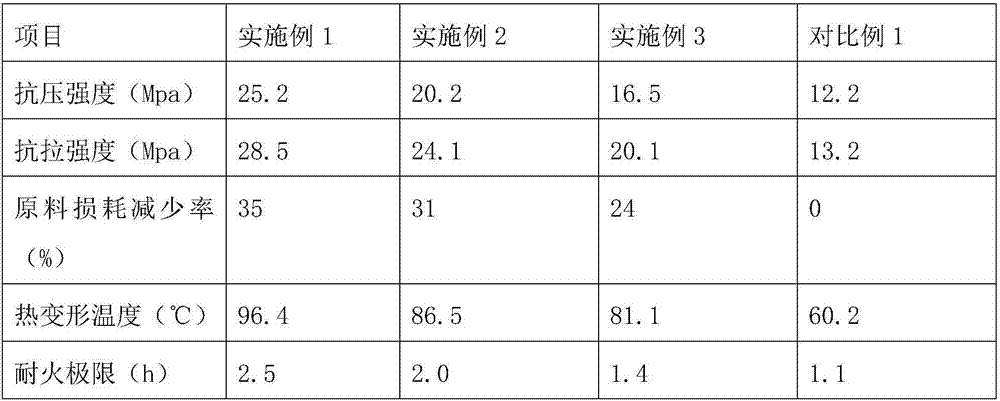

Examples

Embodiment 1

[0036] A new door and window frame, including the following raw materials in parts by weight: 45 parts of polyethylene foam, 35 parts of polypropylene, 23 parts of polyvinyl chloride, 27 parts of hemp pulp fiber, 16 parts of seaweed fiber, 16 parts of chitin fiber, glass 15 parts of fiber, 18 parts of polyester fiber, 30 parts of iron oxide yellow, 14 parts of polyacrylonitrile fiber, 17 parts of calcium stearate, 0.3 part of flame retardant, 0.5 part of adhesive, 0.2 part of compatibilizer, light stabilizer 0.4 parts and 0.3 parts of heat stabilizer.

[0037] Hemp pulp fiber, seaweed fiber and chitin fiber are added to the raw materials. The recycling of these biomass regenerated fibers achieves the purpose of energy saving and environmental protection.

[0038] Hemp pulp fibers are added to the raw materials, and the hemp pulp fibers are strong and tough.

[0039] Glass fiber is added to the raw material, and glass fiber has the advantages of heat resistance, non-combustibi...

Embodiment 2

[0052]A new door and window frame, including the following raw materials in parts by weight: 40 parts of polyethylene foam, 30 parts of polypropylene, 15 parts of polyvinyl chloride, 20 parts of hemp pulp fiber, 13 parts of seaweed fiber, 14 parts of chitin fiber, glass 12 parts of fiber, 15 parts of polyester fiber, 23 parts of iron oxide yellow, 11 parts of polyacrylonitrile fiber, 14 parts of calcium stearate, 0.1 part of flame retardant, 0.3 part of adhesive, 0.1 part of compatibilizer, light stabilizer 0.3 parts and 0.1 parts of heat stabilizer.

[0053] Hemp pulp fiber, seaweed fiber and chitin fiber are added to the raw materials. The recycling of these biomass regenerated fibers achieves the purpose of energy saving and environmental protection.

[0054] Hemp pulp fibers are added to the raw materials, and the hemp pulp fibers are strong and tough.

[0055] Glass fiber is added to the raw material, and glass fiber has the advantages of heat resistance, non-combustibil...

Embodiment 3

[0068] A new door and window frame, comprising the following raw materials in parts by weight: 50 parts of polyethylene foam, 40 parts of polypropylene, 31 parts of polyvinyl chloride, 34 parts of hemp pulp fiber, 19 parts of seaweed fiber, 18 parts of chitin fiber, glass 18 parts of fiber, 21 parts of polyester fiber, 37 parts of iron oxide yellow, 17 parts of polyacrylonitrile fiber, 20 parts of calcium stearate, 0.5 part of flame retardant, 0.7 part of adhesive, 0.3 part of compatibilizer, light stabilizer 0.5 parts and heat stabilizer 0.5 parts.

[0069] Hemp pulp fiber, seaweed fiber and chitin fiber are added to the raw materials. The recycling of these biomass regenerated fibers achieves the purpose of energy saving and environmental protection.

[0070] Hemp pulp fibers are added to the raw materials, and the hemp pulp fibers are strong and tough.

[0071] Glass fiber is added to the raw material, and glass fiber has the advantages of heat resistance, non-combustibili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com